Controlling melt fracture in bimodal resin pipe

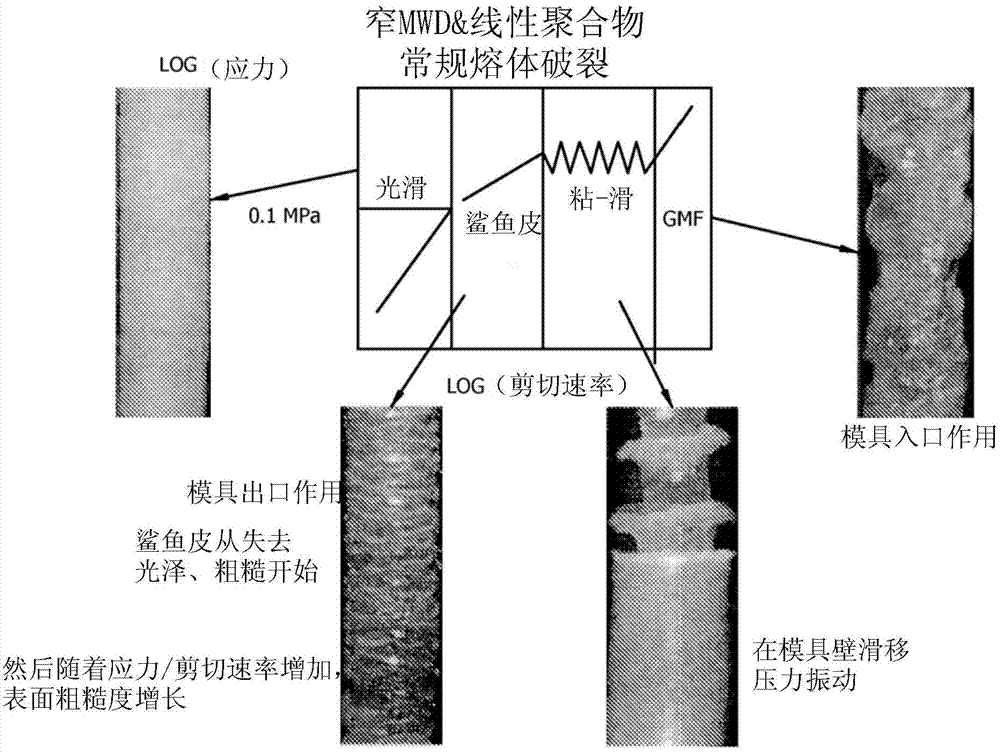

A melt fracturing, polyethylene resin technology, used in pipes, rigid pipes, molecular entity identification, etc., can solve problems such as surface irregularity, reduced production speed, melt fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

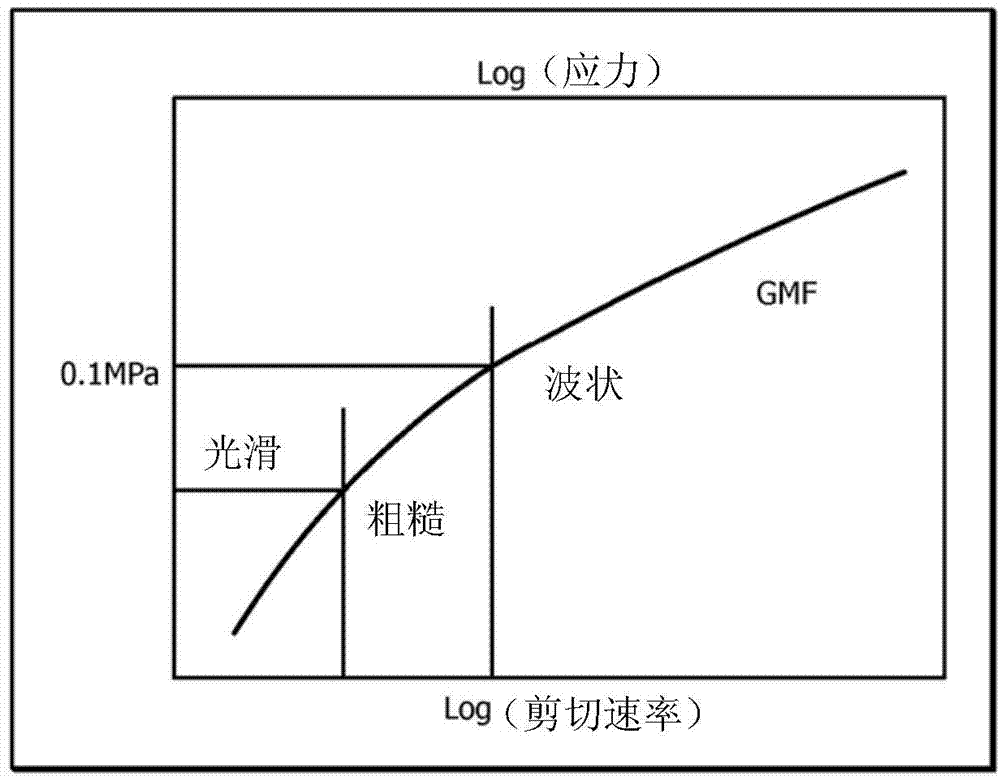

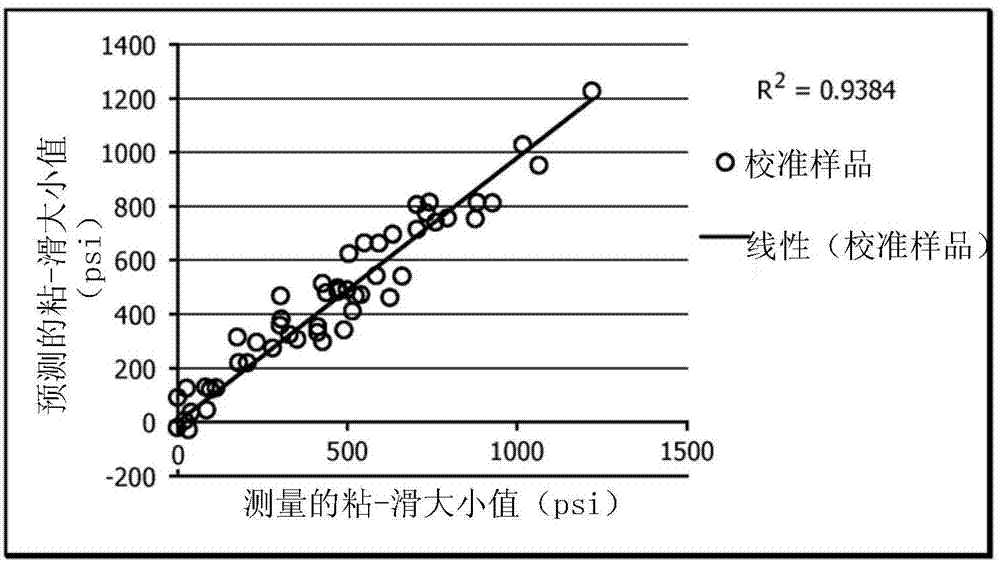

[0127] A first embodiment, which is a method for improving the processing of polyethylene resins, comprises obtaining a plurality of multimodal metallocene-catalyzed polyethylene samples; measuring the shear rate of the plurality of multimodal metallocene-catalyzed polyethylene samples using capillary rheometry Shear stress as a function of shear rate, where measurements yield values for slip-viscosity magnitude, stress for smooth-to-rough transition, and shear rate for smooth-to-rough transition; Individual multimodal metallocene-catalyzed polyethylene resins having a reduced tendency to melt fracture from a slip-stick magnitude greater than about 300 psi, a smooth-to-rough transition stress greater than about 90 kPa, and greater than about 10 s -1 Shear rate characterization of the smooth-to-rough transition.

no. 2 approach

[0128] A second embodiment, which is the method of the first embodiment, wherein each of the plurality of multimodal metallocene-catalyzed polyethylene samples comprises a polymer blend.

no. 3 approach

[0129] A third embodiment, which is the method of any one of the first to second embodiments, wherein each of the plurality of multimodal metallocene-catalyzed polyethylene samples includes a high molecular weight component and a low molecular weight component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com