Highly viscous, largely amorphous polyolefin

A technology of polyolefin and polypropylene polymer, applied in the field of preparing such polyalpha-olefin, can solve the problems of poor operability, narrow molecular weight distribution, adverse effect of viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 8

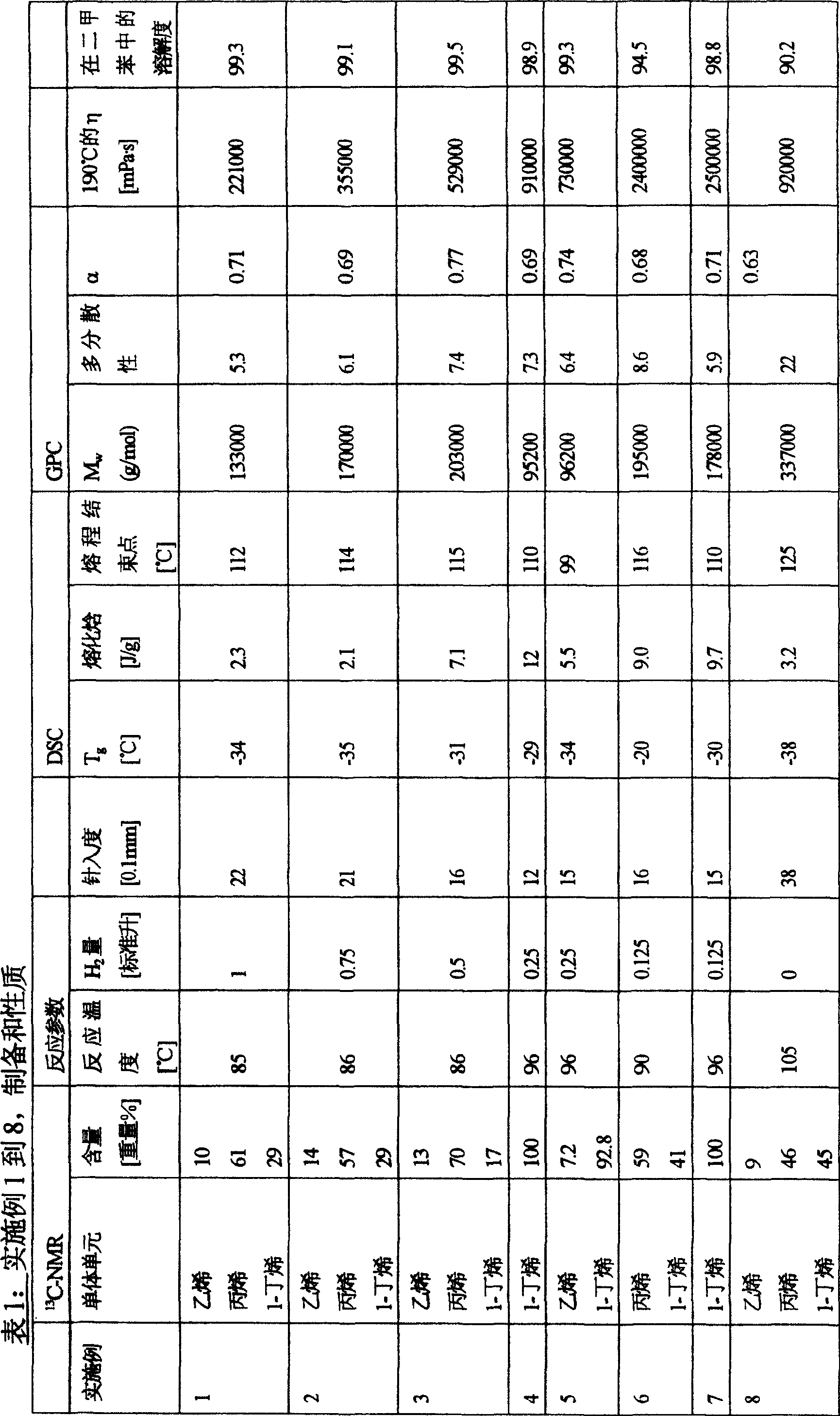

[0078] Examples 1 to 8: Preparation of polyolefins

[0079] Using TiCl reduced with Al 4 (TiCl 3 0.33AlCl 3 ) form of crystalline titanium trichloride and triisobutylaluminum (weight ratio 1:4) composition of the mixed catalyst, the monomer in n-butane given in Table 1 at the temperature given in Table 1, in The polymerization was carried out in a laboratory autoclave, optionally using hydrogen as molar mass regulator. The pressure is 22 to 25 bar. The monomers ethylene and propylene were metered in continuously over a reaction time of 3 hours; the monomer 1-butene and optionally higher olefins were added first. After 3 hours, the reaction mixture was mixed with isopropanol to terminate the reaction. Unreacted monomers and the solvent n-butane were evaporated in an evaporator. The polyolefin melt exits at a temperature of about 190°C.

[0080] The analytical values of the obtained products are listed in Table 1.

[0081] Measurement method 1 For determining solubi...

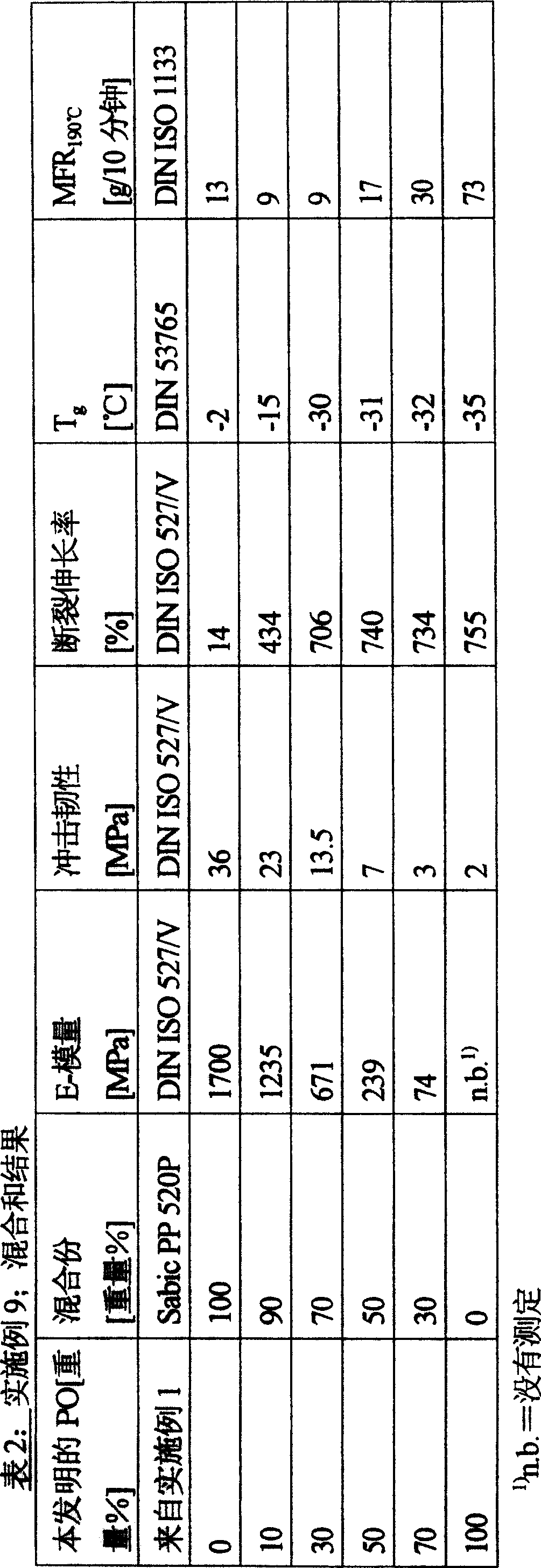

Embodiment 9

[0087] Mixtures of Sabic PP520P, isotactic polypropylene and the product from Example 1 in different quantitative ratios were prepared on an ENTEX extruder at 190° C. and a mixing time of 10 minutes. Table 2 gives details and results.

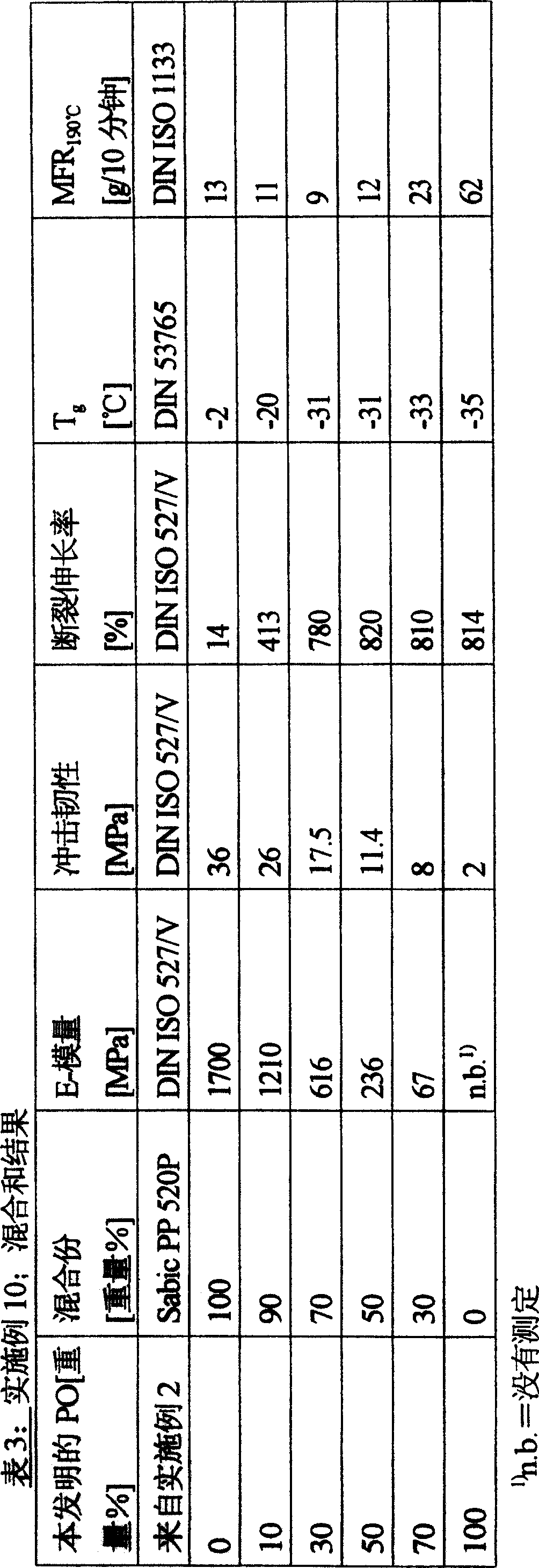

Embodiment 10

[0089] As Example 9; instead of the product from Example 1, the product from Example 2 was used. Table 3 gives details and results.

[0090] As can be seen from Examples 9 and 10, in the scope of mixing a small amount of the polyolefin of the present invention (up to about 30% by weight), compared with the corresponding composition ratio, the elongation at break is obviously improved, and the glass transition point T g Significantly lower. Elongation at break is e.g. related to films, while T g The position of α significantly affects the low temperature impact toughness. The melt flow in this range is surprisingly small, so that this molding compound is well suited for extrusion.

[0091]

[0092]

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com