Paddy rice hole dibbler

A kind of on-demand machine and acupoint technology, which is applied in the field of agricultural machinery, can solve the problems of reduced lodging resistance, failure to improve the root growth environment, new root growth and root penetration, and root support force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

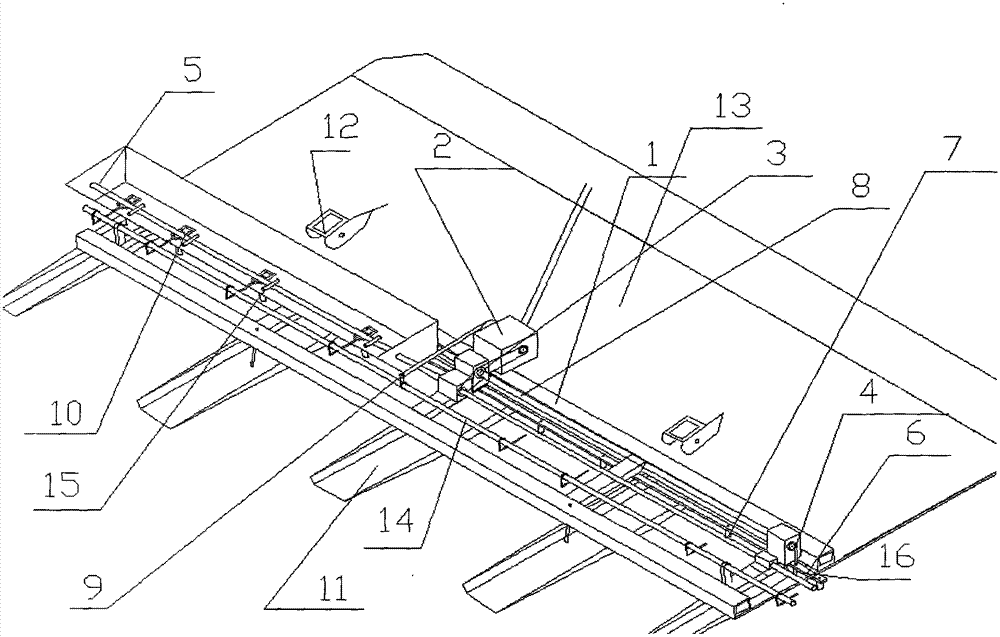

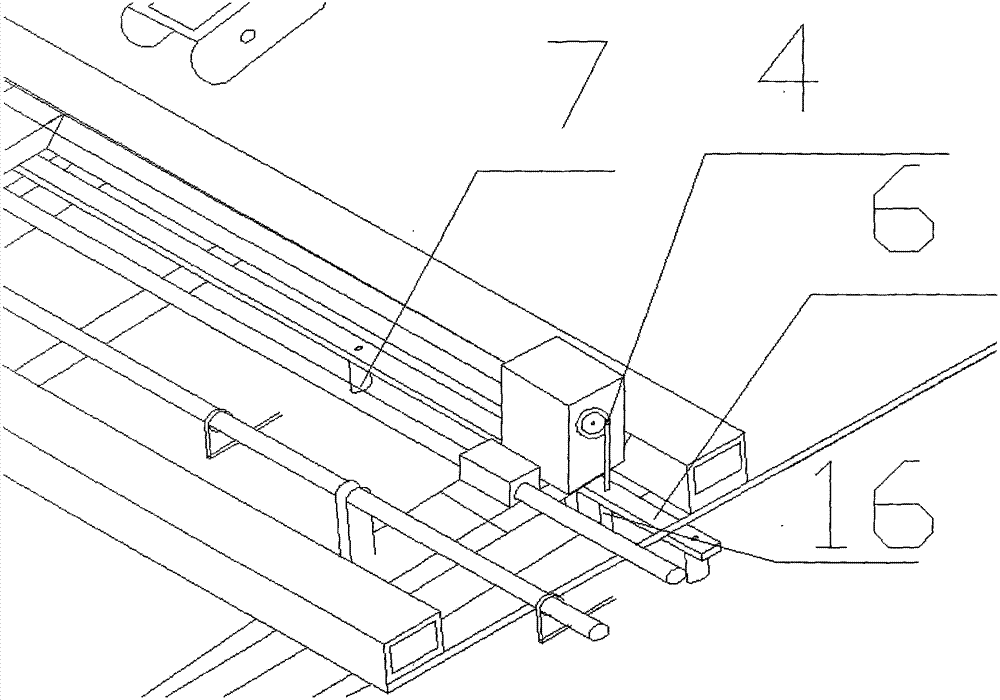

[0015] Such as Figure 1-2 Shown, the present invention provides a kind of paddy acupoint planting machine, and this planting machine comprises boat-shaped flat dragging bottom plate 13, frame 1, transmission device 2, speed changer 3, is provided with eccentric wheel 4, square pipe 6, pound hole stick 7, Front cross axis 8. The front end of the boat-shaped flat drag base plate 13 is provided with a traction claw 12 connected to the traction frame of the locomotive, and the tail portion of the boat-shaped flat drag base plate 13 is provided with a stern drag plate 11 that stretches out backwards and plays a balancing role. The frame 1 can It is disassembled and installed on the stern drag plate 11, the front cross shaft 8 is fixed on the frame 1 with movable bearing bearings, the transmission device 2 is connected with the power locomotive, and the transmission device 2 is provided with the driving gear of the eccentric wheel 4 and the speed changer 3 , the speed changer 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com