Shaft seat of balance shaft

A technology of balance shaft and shaft seat, which is applied in interconnection system, suspension, transportation and packaging, etc. It can solve the problems of small bearing area, affecting service life, easy fracture of square steel frame and side guard plate, etc., and achieves increased Strength, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

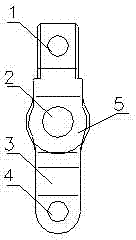

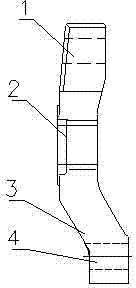

[0012] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The accompanying drawing is a specific embodiment of the present invention. It includes a shaft seat body 5, and the shaft seat body 5 is respectively provided with a cross shaft mounting hole 2 for connecting a cross shaft and a cross beam mounting hole 1 for connecting a cross beam. The characteristic is that the shaft seat adopts an elongated structure, Both the lower part of the horizontal axis mounting hole 2 on the shaft seat body 5 is also provided with a lower support body 3, and the lower part of the lower support body 3 is also provided with a connecting mechanism fixedly connected with the lower support body of the shaft seat on the other side, so that both sides The axle seat is connected as a whole to increase the strength of the axle seat. The lower support body 3 is parallel to the inner surface of the bracket that fixes the horizontal axis in the middle of the axle seat body 5; it can share the force carri...

Embodiment 2

[0014] For the convenience of manufacture, the shaft hole and the connecting shaft can also adopt a clearance fit. In order to ensure a firm connection, positioning pin holes are set in the radial direction of the shaft hole and the connecting shaft 4, and the positioning pin holes are installed in the positioning pin holes. pin. Other parts are identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com