Novel LED (light emitting diode) lamp tube

A new type of LED lamp technology, applied in lighting and heating equipment, point light sources, lighting devices, etc., can solve the problems of long production process, cumbersome, lifespan reduction, etc., to improve the utilization rate of light, simple maintenance process, Effects that increase the glow range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

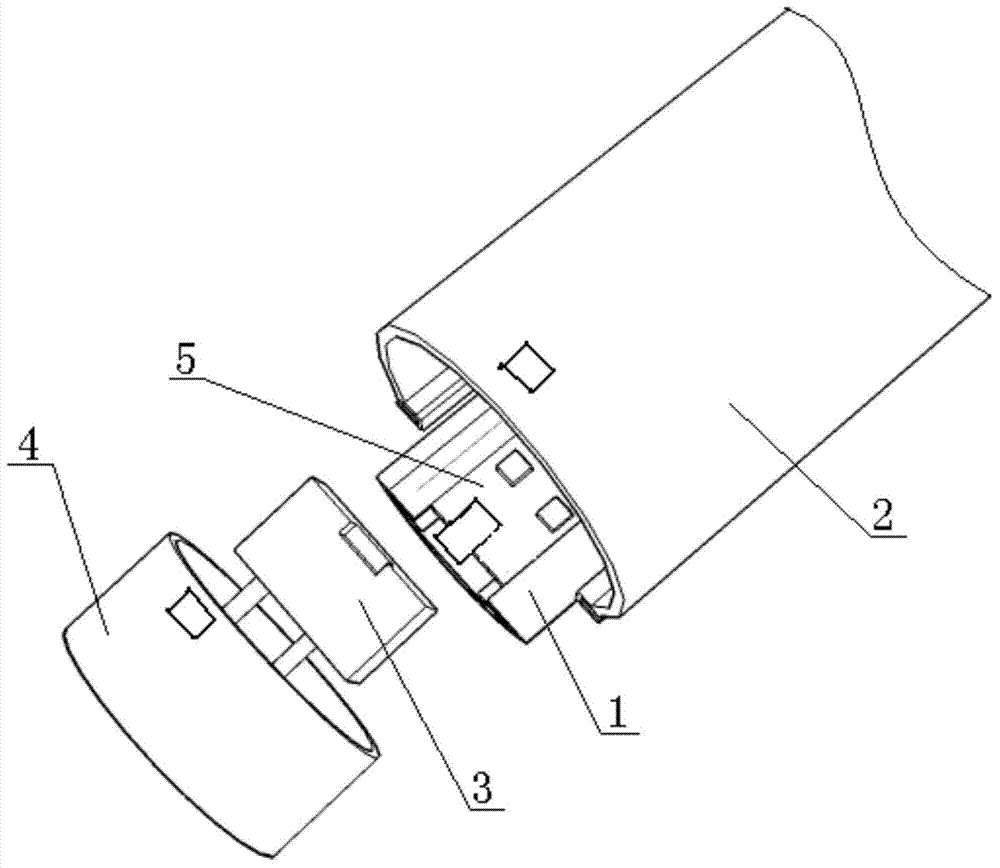

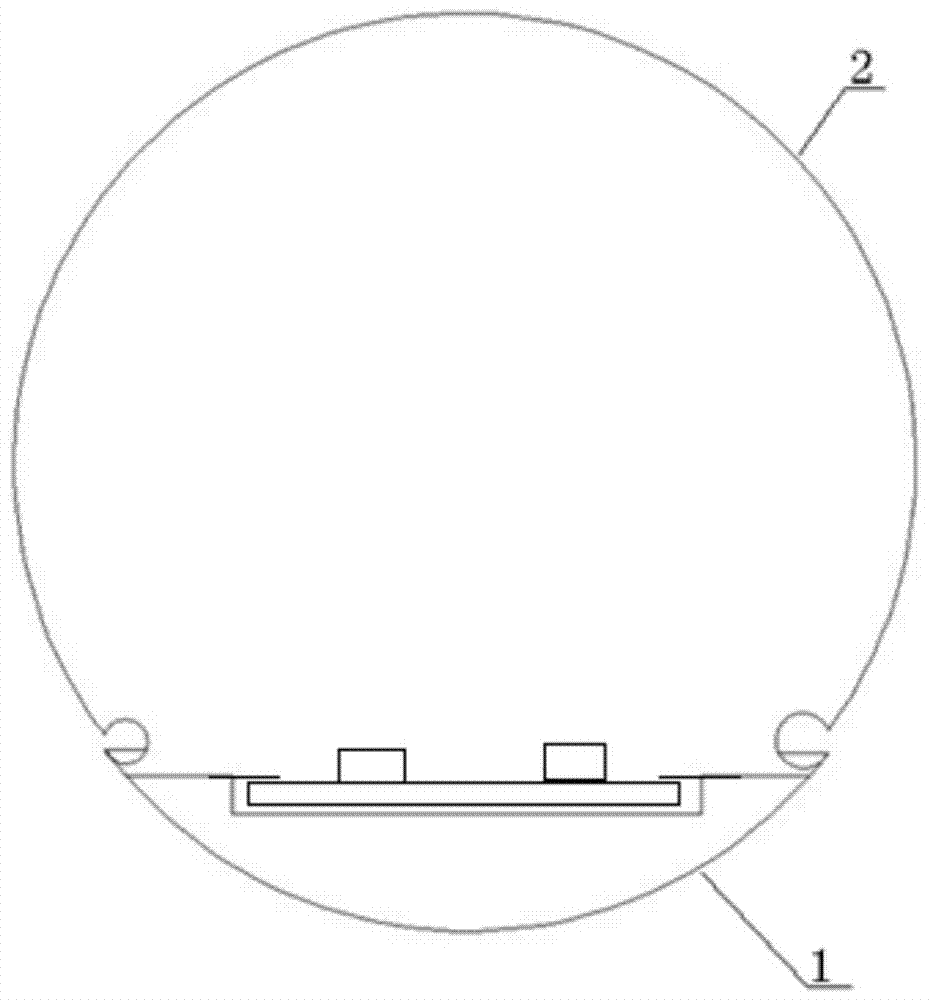

[0026] Such as figure 1 , 2 As shown, the novel LED lamp of the present invention includes an aluminum shell 1, a lampshade 2, a driving power supply 3, a plug 4 and a substrate 5;

[0027] The lampshade 2 is provided with a casing slot, and the aluminum casing 1 is provided with a buckle corresponding to the casing slot, and the lampshade 2 and the aluminum casing 1 are clipped together;

[0028] The aluminum housing 1 is provided with a substrate clamping slot, and the aluminum housing 1 is clamped with the substrate 5;

[0029] The outer side of the plug 4 is provided with a bayonet, and the aluminum casing 1 and the lampshade 2 are provided with corresponding clips, the aluminum casing 1 and the lampshade 2 form a lamp tube, and the two ends of the lamp tube are snapped into the plug 4;

[0030] The inner side of the plug 4 where the drive power supply 3 is installed is provided with a drive card slot and a pin hole, the drive power supply 4 is plugged into the drive car...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap