Isolator system for a pressure transmitter

An isolation system and transmitter technology, applied in the field of isolation systems, can solve the problems of not inhibiting the rapid response of the pressure sensor, slowing down the pressure sensor, restricting the flow of oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

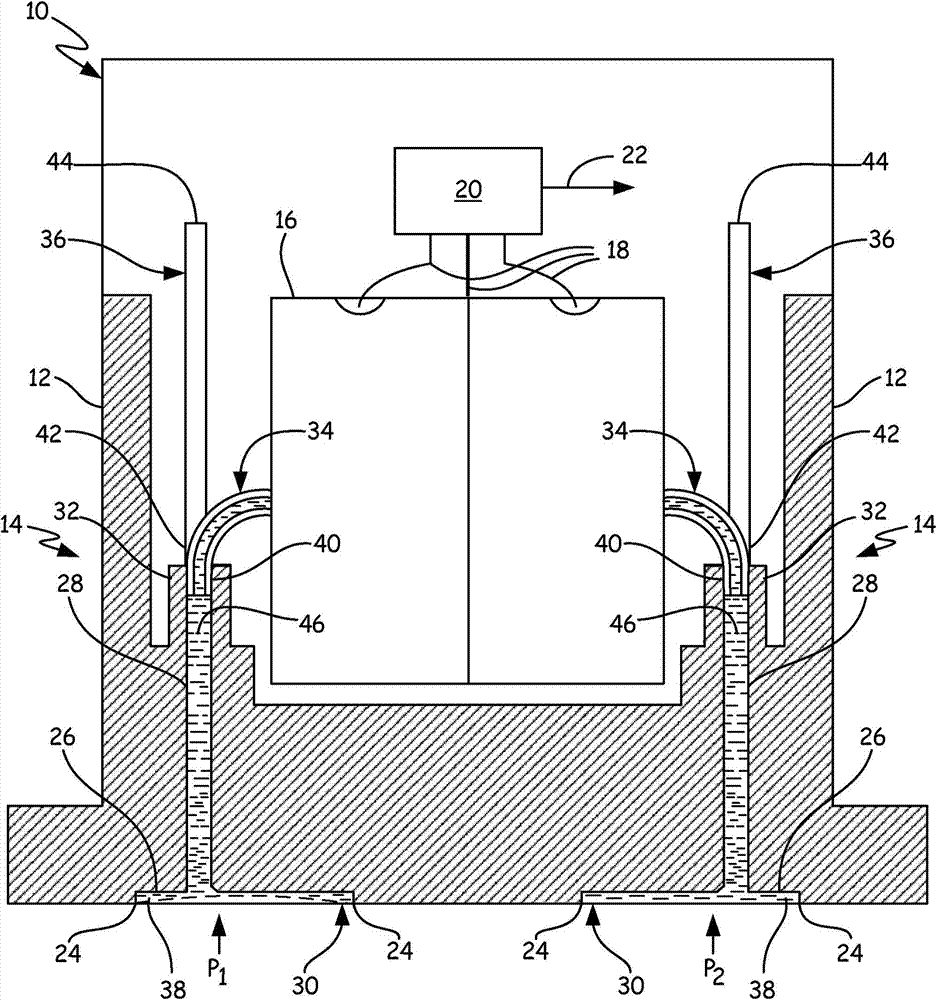

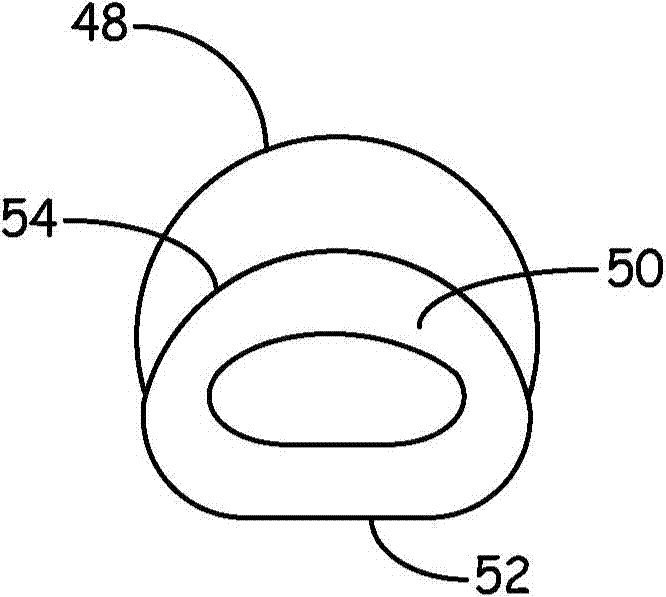

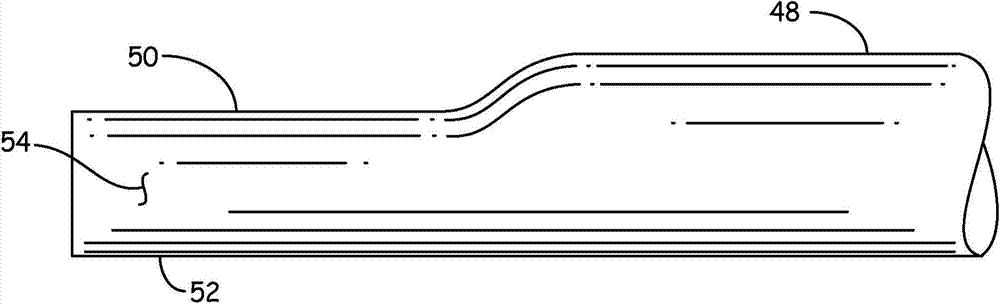

[0011] Embodiments of the present invention provide an isolation system suitable for industrial pressure transmitters. An isolation system embodying the invention employs the improvement of the invention to a pressure transmitter comprising an oil fill tube and a sensor tube shaped to fit together in a single port, as in the US assigned to Rosemount Corporation Described in "PRESSURE TRANSMITTER WITH IMPROVED ISOLATOR SYSTEM" Patent 6,662,662, which is incorporated herein by reference.

[0012] In an embodiment of the invention, the isolation system is improved by allocating a majority of the total cross-sectional area of the sensor tube and the oil-filled tube to the sensor tube. The larger sensor tube cross-sectional area reduces the flow impedance through the sensor tube without increasing the size of the port or the amount of oil filled in the port. As a result, in operation, the response time between a pressure change at the isolation diaphragm and a pressure change de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com