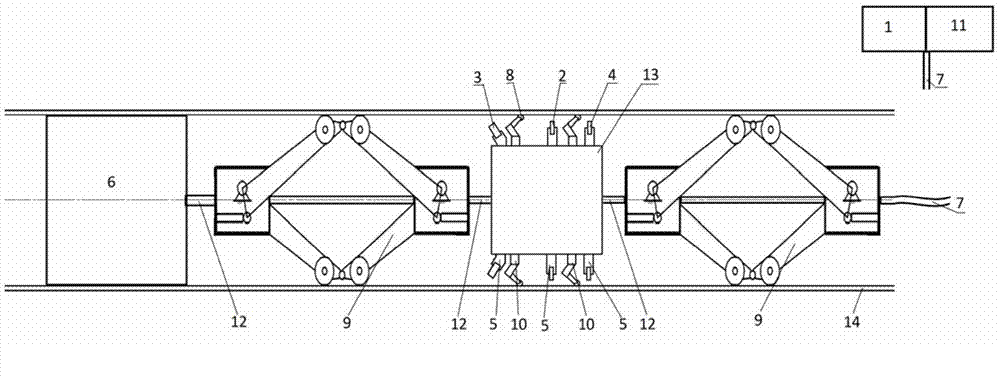

Pressure pipeline ultrasonic internal detection automation device

An automatic device and pressure pipeline technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, can solve problems such as low detection sensitivity and resolution, complex boundary conditions, and difficult to determine safety conditions, so as to improve detection efficiency and solve acoustic problems. The effect of energy loss and not easy to miss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

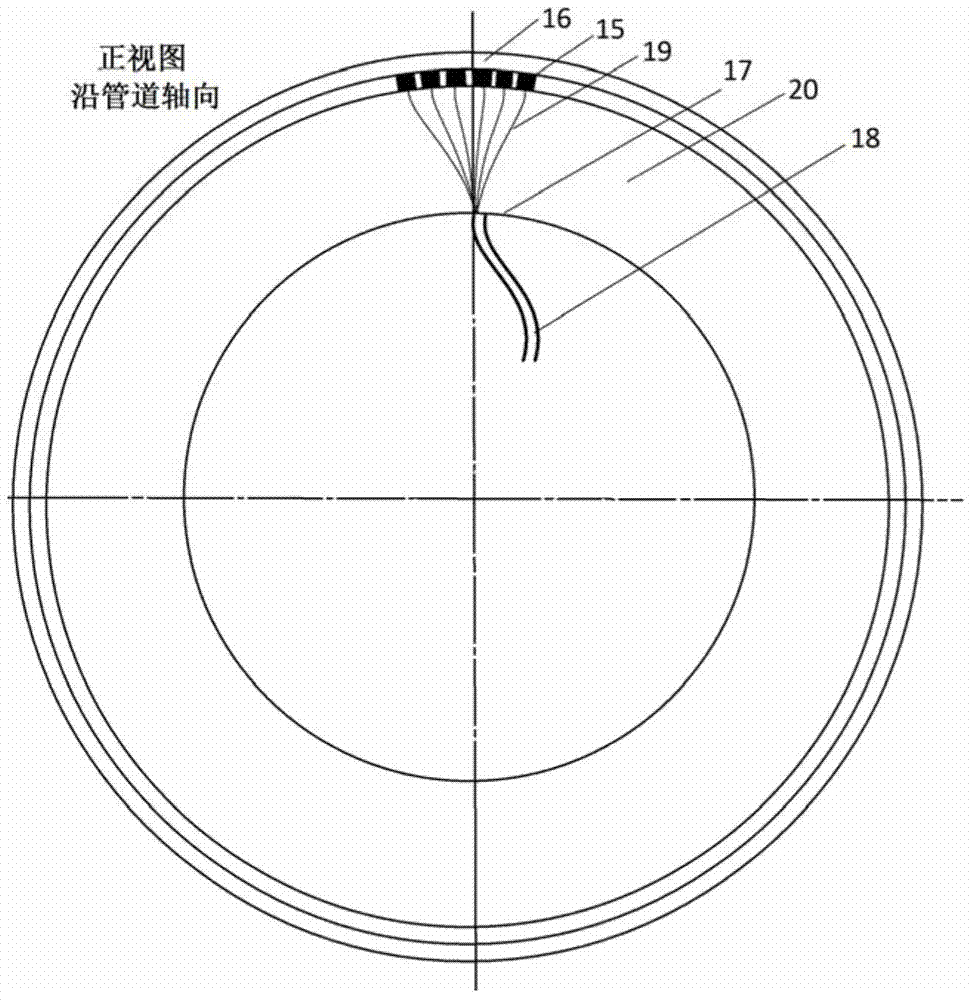

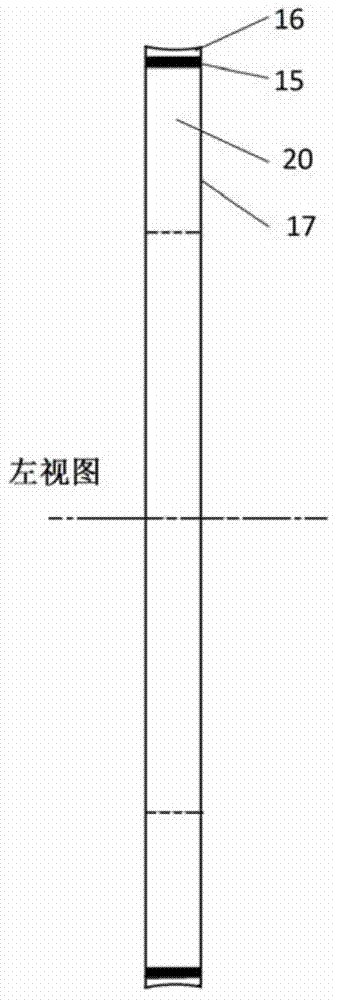

[0089] Design a cylindrical phased array probe assembly with 452 array elements (such as Figure 13 shown), the cylindrical phased array probe assembly is composed of 4 phased array probes with 128 array elements, and the number of channels participating in the focal law of the present invention is 16, so there are 15 channels between two adjacent phased array probes Array elements overlap, such as Figure 12 As shown, the phased array probe consists of 128 elements numbered from 1st to 128th, among which the 114th to 128th array elements are also numbered from the 1st to the 15th element of the phased array probe from 2, The circumferential focusing of the disk phased array probe assembly adopts electronic focusing technology, and the corresponding focusing law is designed to control the emission of the independent piezoelectric wafers of the phased array probe 16. The ultrasonic waves emitted by each unit of the array are superimposed to form a new wave front, so that It fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com