Whole automobile/plate environment test cabin for automobile and humidity control method for test cabin

An environmental test chamber and test chamber technology, applied in the field of environmental test chambers, can solve problems such as single function and small volume, and achieve the effects of ensuring test accuracy, reducing energy consumption, and improving control accuracy and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

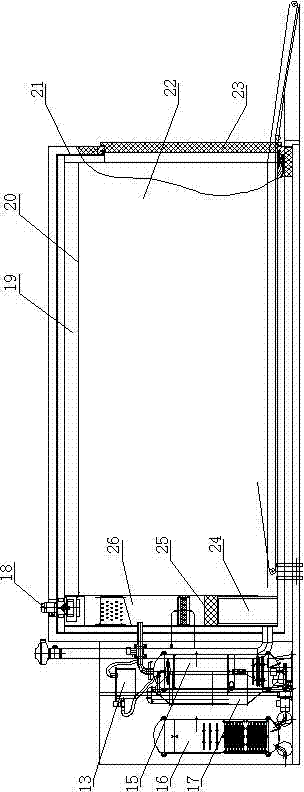

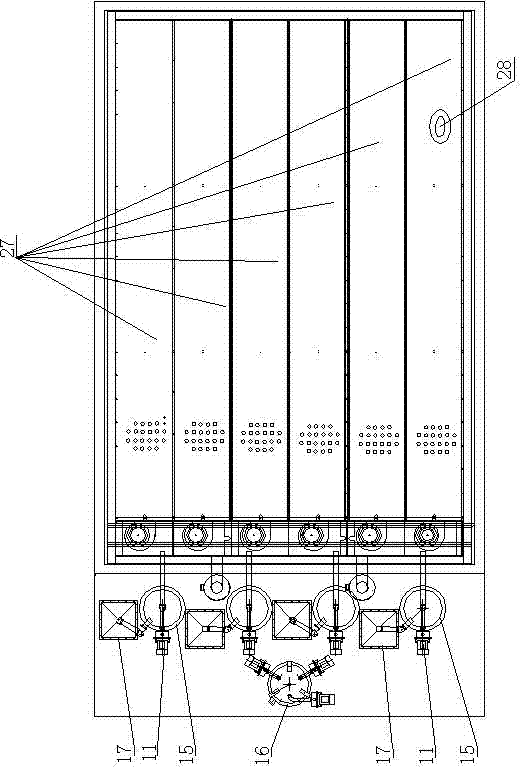

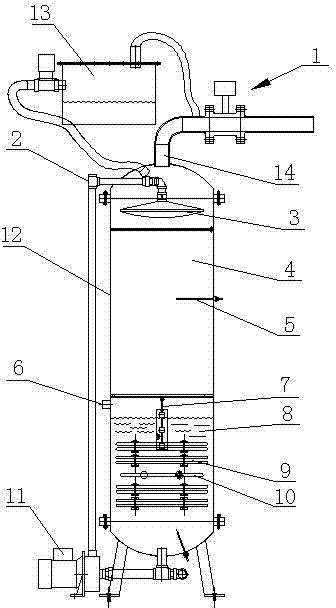

[0020]As shown in the accompanying drawings, a vehicle / plate environment test cabin includes an experimental cabin, a fresh air device connected to the experimental cabin, and a filter device 17 connected to the fresh air device. The experimental cabin body adopts an integrally welded stainless steel liner nested structure, and the experimental cabin body includes an internal test cabin 22 and an insulated box 21 arranged outside the test cabin 22 . The test chamber is integrally welded with mirror stainless steel and polished around to make a certain radian. One end of the test cabin 22 is provided with a fresh air guide groove 26, and the top of the test cabin 22 is provided with a static pressure cabin 19, the height of the static pressure cabin is 250mm, and the static pressure cabin 19 includes a plurality of air supply ducts 27 arranged side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com