Connecting rod mechanism

A connecting rod mechanism and connecting rod technology, applied in the direction of agricultural machinery, agricultural machinery and implements, applications, etc., can solve problems such as fracture, bending, and complex structure, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

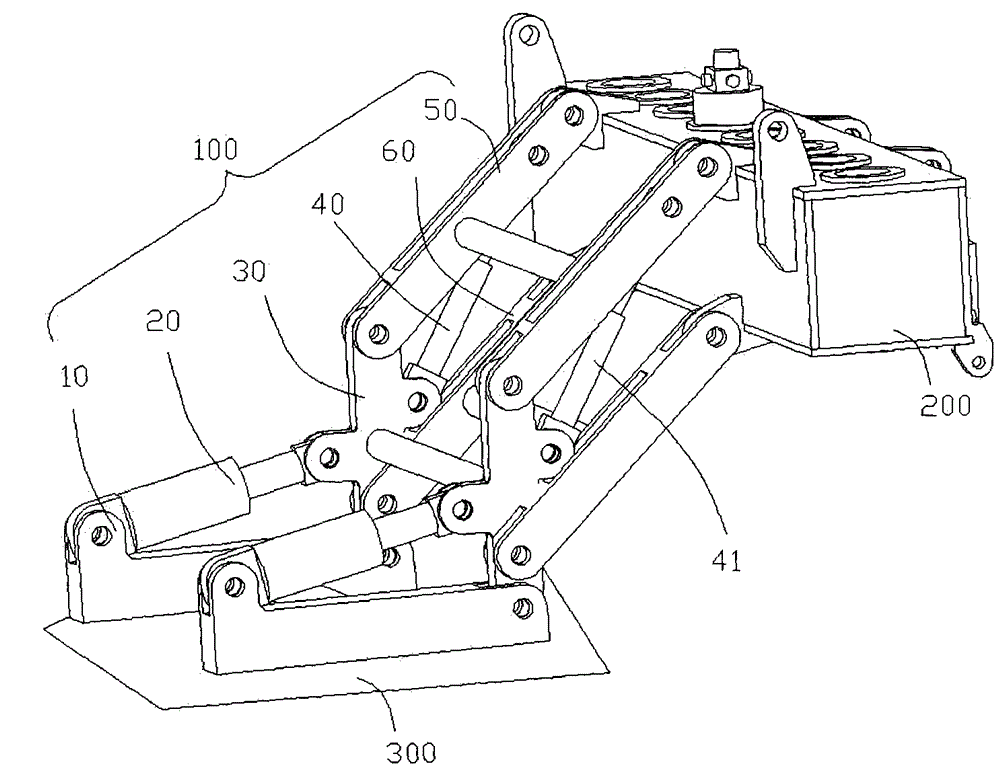

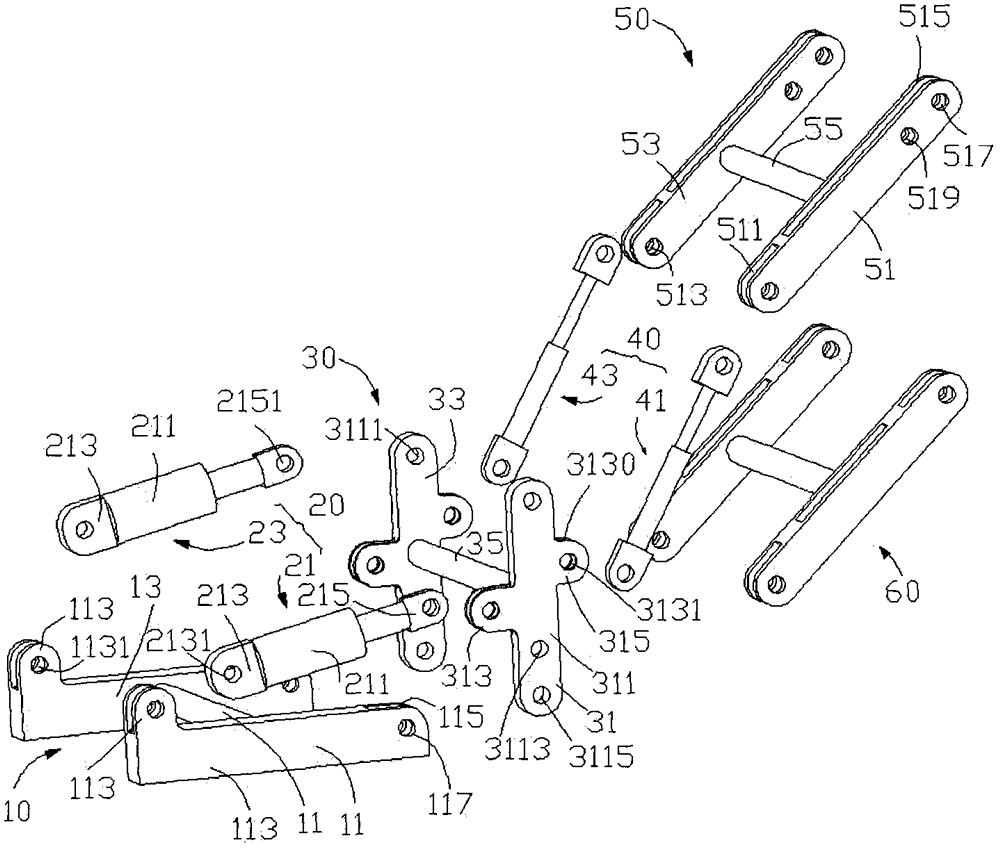

[0023] see figure 1 , In a preferred embodiment of the present invention, a link mechanism 100 is used to connect a powder ridge head 200 and a support table 300, and includes a base 10, a first driving part 20, a swinging member 30, a The second driving part 40 , a master link 50 and a slave link 60 . In this embodiment, several drill pipes (not shown in the figure) are installed on the powder ridge head 200, and the several drill pipes are used for planting various crops in the powder ridge, such as rice, corn, sugarcane, soybean, etc. Land, in this embodiment, the field or land is defined as the working surface of the several drill pipes.

[0024] read on figure 1 and figure 2 , the base 10 is mounted on the supporting platform 300 by common fixing means, such as screws, welding, etc. The base 10 includes a first support block 11 , a second support block 13 and a connecting rod 15 . The connecting rod 15 is substantially vertically connected to the first support block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com