Wedge pressurized sawtooth groove double-sided dehydration upper press belt filter press

A technology of double-sided dehydration and pressing belt, which is applied in the direction of filtration separation, moving filter element filter, separation method, etc. It can solve the problems of inability to achieve separation and increase concentration, inability to meet high concentration requirements, and pulp loss, so as to increase dehydration Effectiveness, reasonable structure, and the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

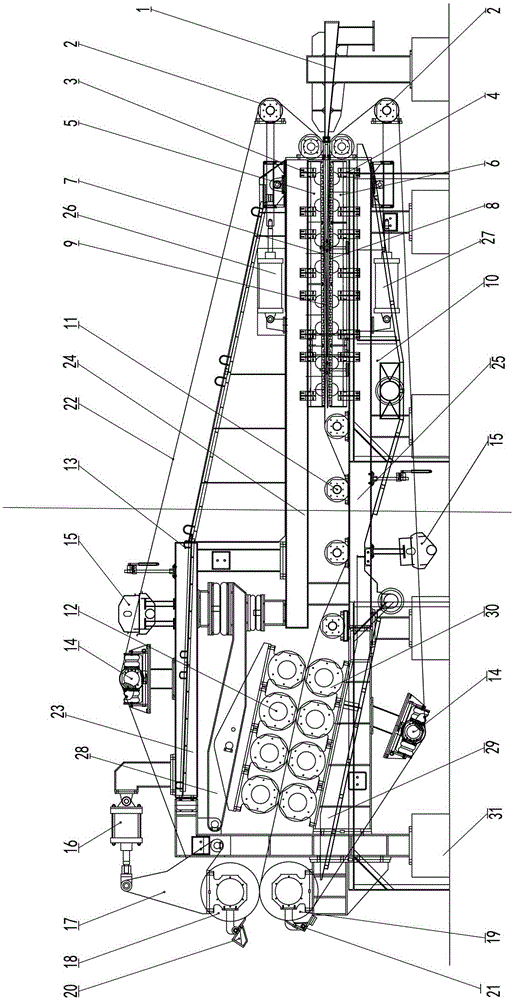

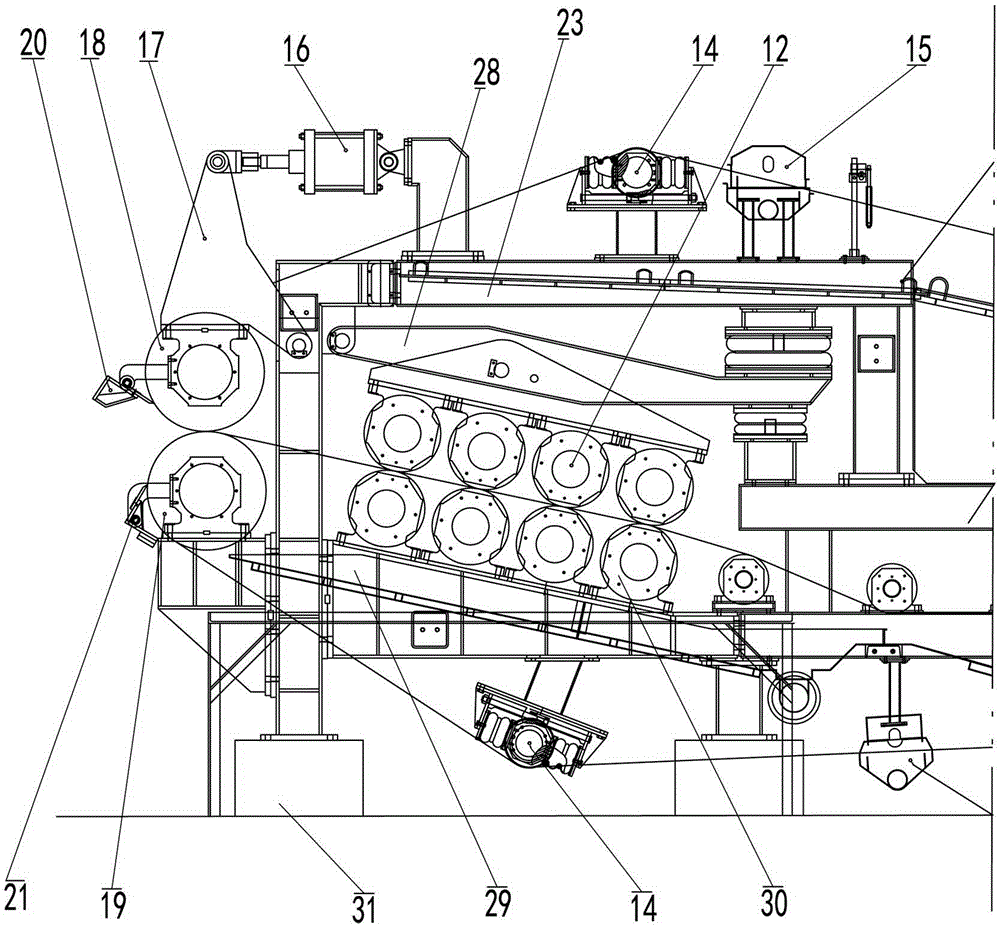

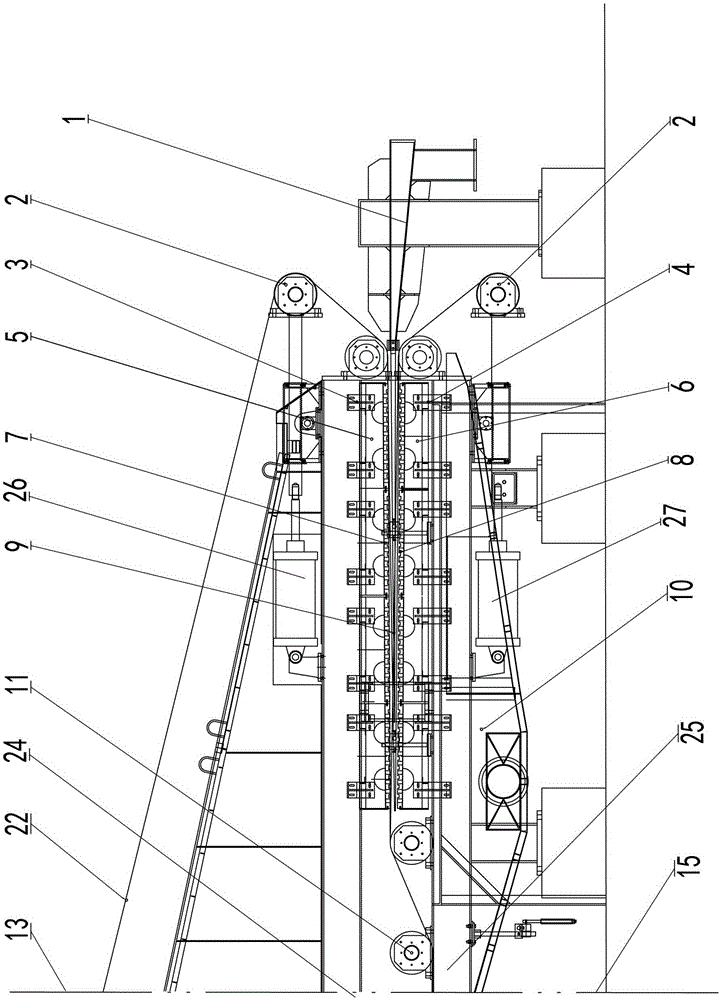

[0041] see figure 1 , Embodiment 1 The wedge-shaped supercharged sawtooth groove double-sided dehydration upper press belt filter press is mainly composed of a frame, a pressing area, a driving device, a feeding spray device, a wedge-shaped supercharged sawtooth groove double-sided dewatering plate, a rotary dehydration It is composed of device, scraper unloading device, deviation correction device, pneumatic tensioning device, water spray cleaning device and water receiving tank device. The wedge-shaped pressurized sawtooth groove double-sided dehydration zone is divided into wedge-shaped pressurized sawtooth groove double-sided dehydration with an angle greater than 0° and less than or equal to 3° between the upper filter and the lower filter. The inlet is larger than the outlet. According to the operation of the filter to achieve pressurization, according to the sawtooth groove and round hole of the dewatering plate to achieve double-sided detachment effect, the driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com