Automobile ignition coil sheath automatic assembly equipment

An automobile ignition coil and automatic assembly technology, applied in metal processing equipment, vehicle parts, transportation and packaging, etc., can solve problems such as low efficiency, wrong installation, and missing installation, and achieve the effect that it is not easy to miss and install wrongly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

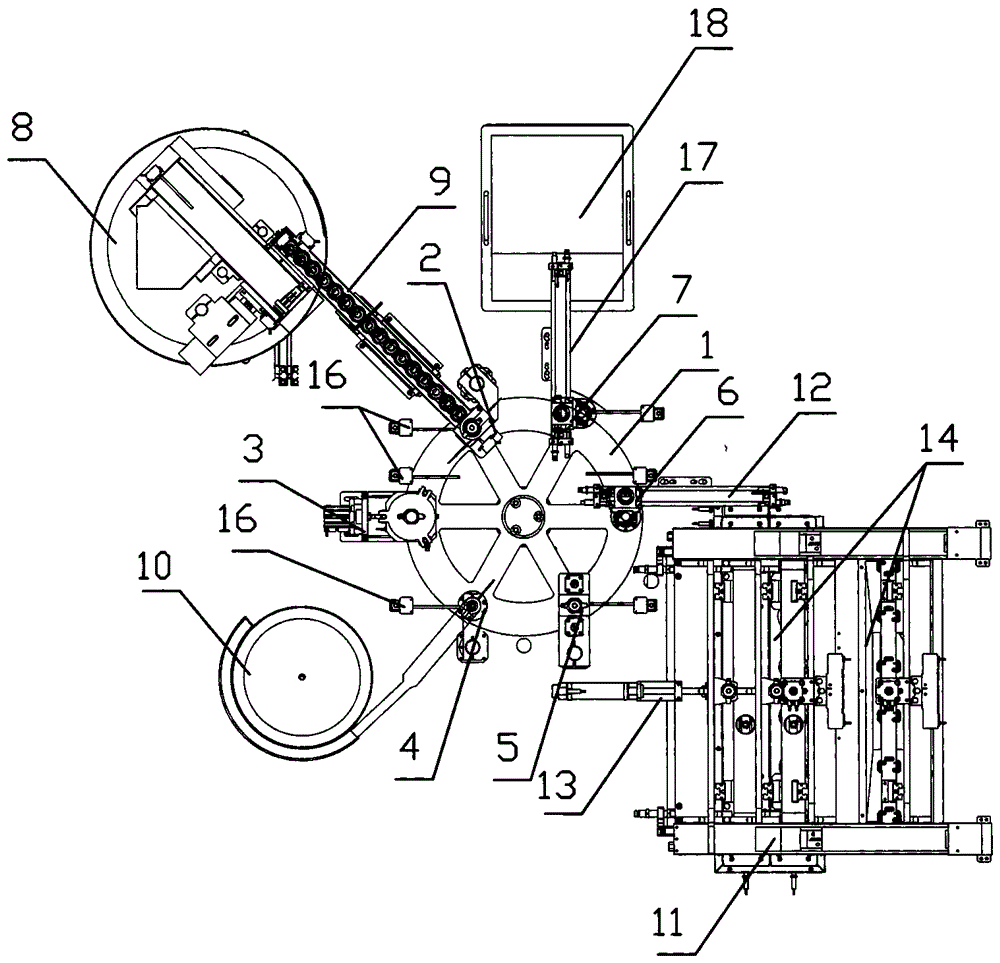

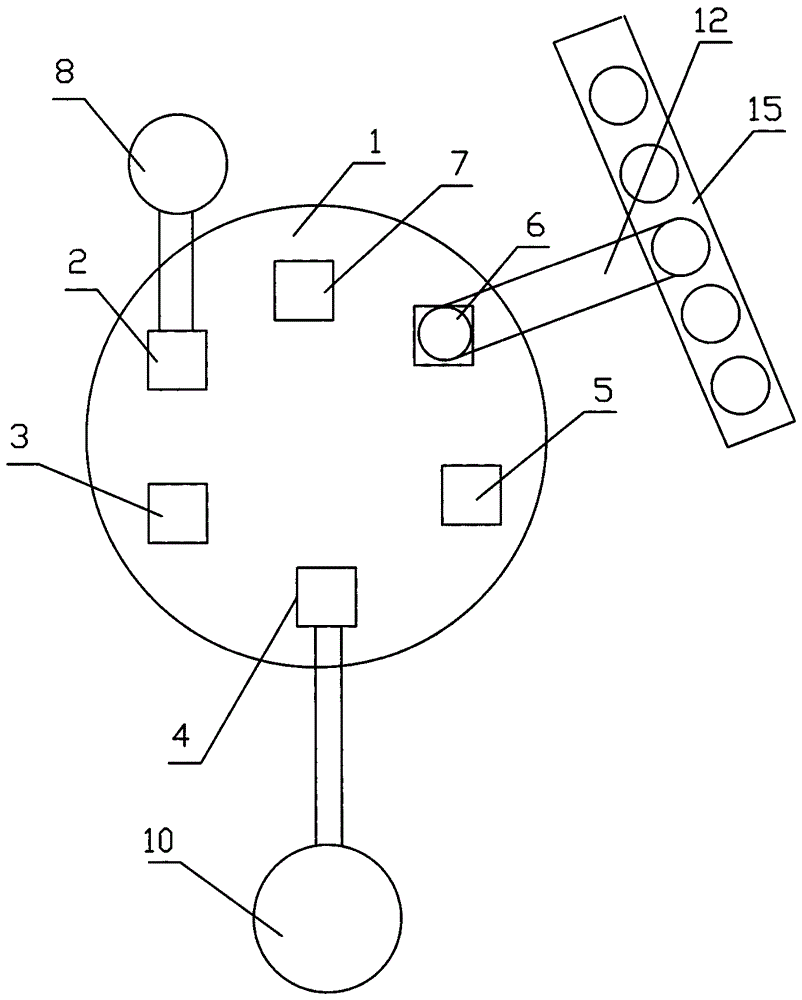

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] combined with figure 1 And attached figure 2 , an automobile ignition coil sheath automatic assembly equipment, it includes a turntable 1, the turntable 1 is provided with six stations evenly distributed; the six stations are sheath connection station 2, blowing station respectively Air cleaning station 3, spring pre-pressing station 4, spring precision pressing station 5, finished product picking station 6 and spare picking station 7; above the sheath connecting station 2, there is a sheath linear feeding 9, the feeding end of the sheath linear feeder 9 is connected with a sheath vibrating plate 8; the discharge end of the sheath linear feeder 9 is equipped with a jacking device for controlling the timing of blanking; A blowing pipe is provided directly above the position 3, and the blowing pipe is connected with a fan; a feeding pipe is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com