Double hole punching equipment for bamboo chip processing

A short-distance, bamboo chip technology, applied to fixed drilling machines and other directions, can solve the problem of low drilling efficiency, achieve low cost, improve processing efficiency, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

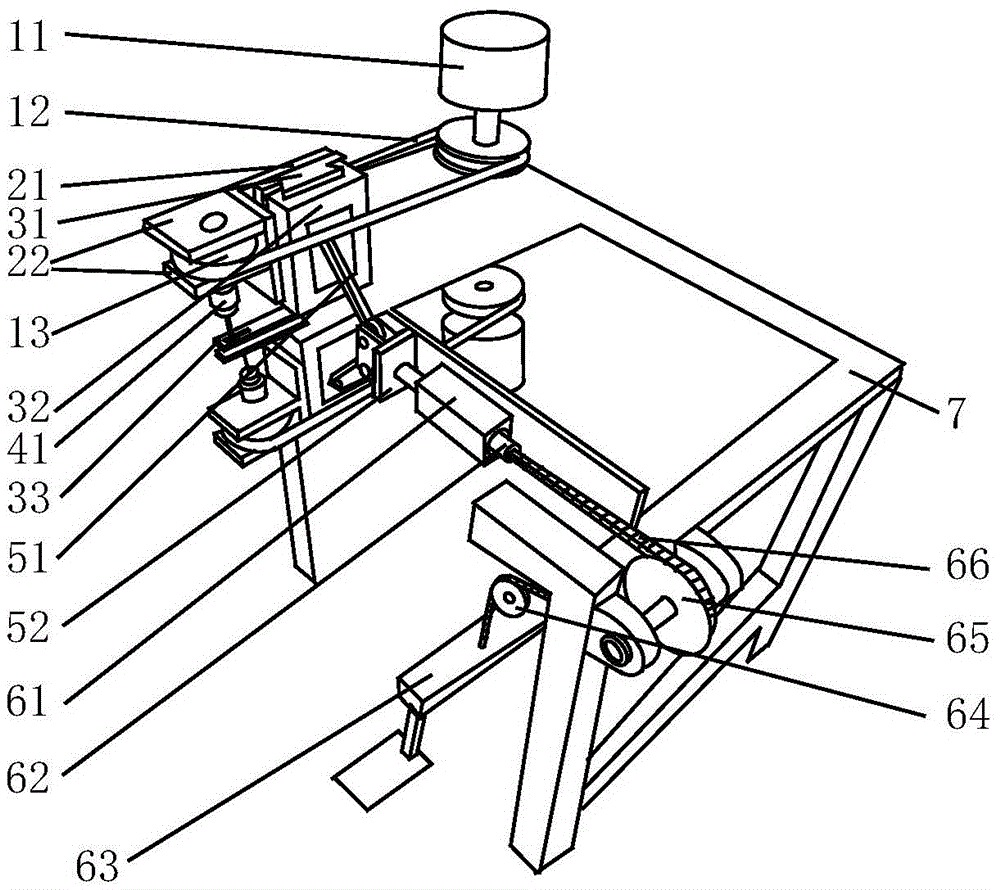

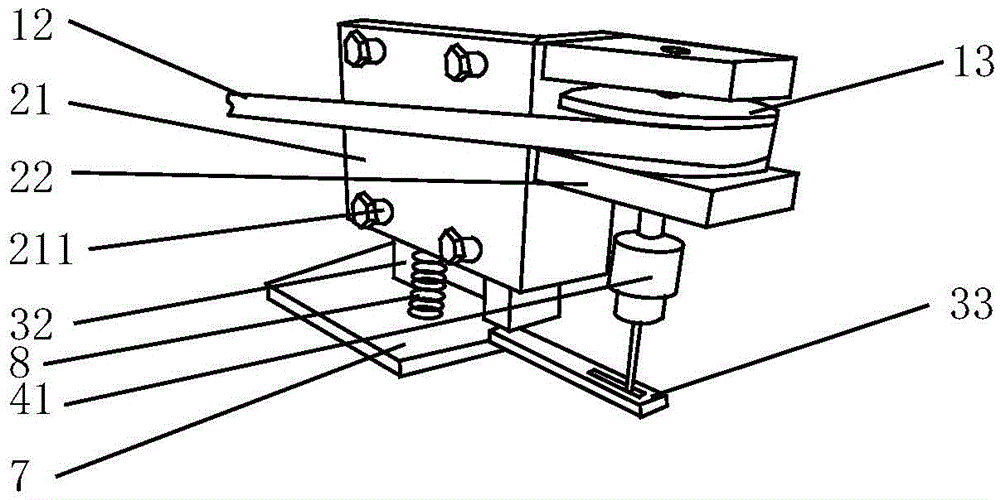

[0042] Now in conjunction with accompanying drawing, the present invention will be further described:

[0043] As shown in the figure, a kind of close-range double-hole equipment for bamboo chip processing includes:

[0044] Rack 7;

[0045] The upper dovetail block 31 is fixed on the frame 7, and the middle part of the upper dovetail block 31 is provided with a through hole;

[0046] The upper dovetail block 32 can move up and down along the upper dovetail groove block 31;

[0047] The upper movable frame 21 is fixed on the upper dovetail block 32, and the upper movable frame 21 is provided with two parallel upper supporting frames 22;

[0048] The upper transmission wheel 13 is installed between the two upper support frames 22;

[0049] The upper drill chuck 41 is fixed with the rotating shaft of the upper transmission wheel 13, and is used to install the drill bit;

[0050] The upper motor 11 is fixed on the frame 7, and is linked with the upper transmission wheel 13 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com