A high-shear high-mixing plasticizing screw

A plasticizing screw and high shear technology, applied in the field of screw, can solve the problems of poor shear and melting effect, difficulty in ensuring uniform mixing of raw materials and additives, and poor mixing performance of the screw.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

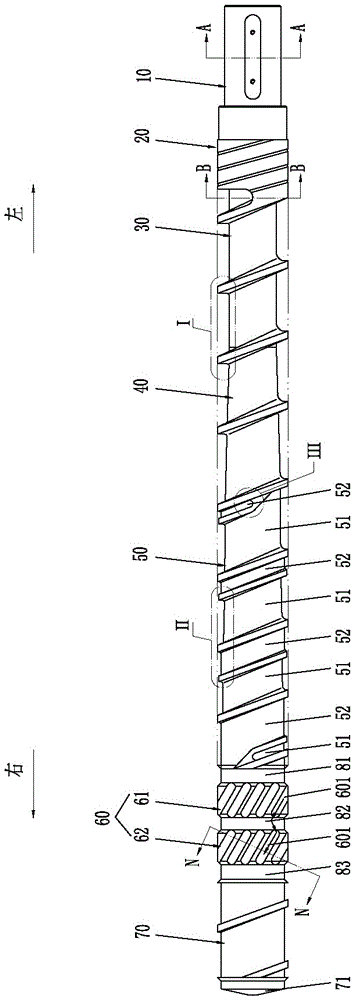

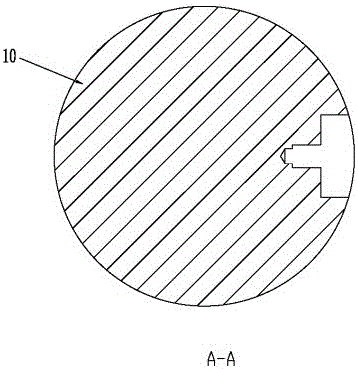

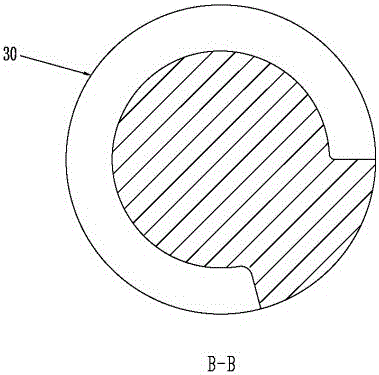

[0035] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the embodiment of the present invention. The high-shear high-mixing plasticizing screw includes a screw body, and the screw body is sequentially provided with a connecting section 10 and a fixing section 20 from left to right. , feed section 30, compression section 40, twin-thread melting section 50, mixing section 60 and discharge section 70, and their respective maximum outer diameters are all equal.

[0036] The feeding section 10, the compression section 20, the double-threaded melting section 50 and the mixing section 60 all include a core column, wherein the core column of the feeding section 10 is the smallest section and remains unchanged, and the mixing section 60 The core column is the largest section and remains unchanged, and all the other core columns gradually become larger from left to right; the core column of the feeding section 10 and the compression section 40 is spiral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com