A kind of preparation method of humidity control material

A technology for humidity-conditioning materials and raw materials, which is applied in chemical instruments and methods, layered products of hydraulic substances, layered products, etc., and can solve the application limitations of humidity-conditioning materials, damage to the porous structure of materials, and poor control of porosity, etc. The problem is to achieve the effects of low cost of raw materials, low synthesis temperature, and saving production and preparation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

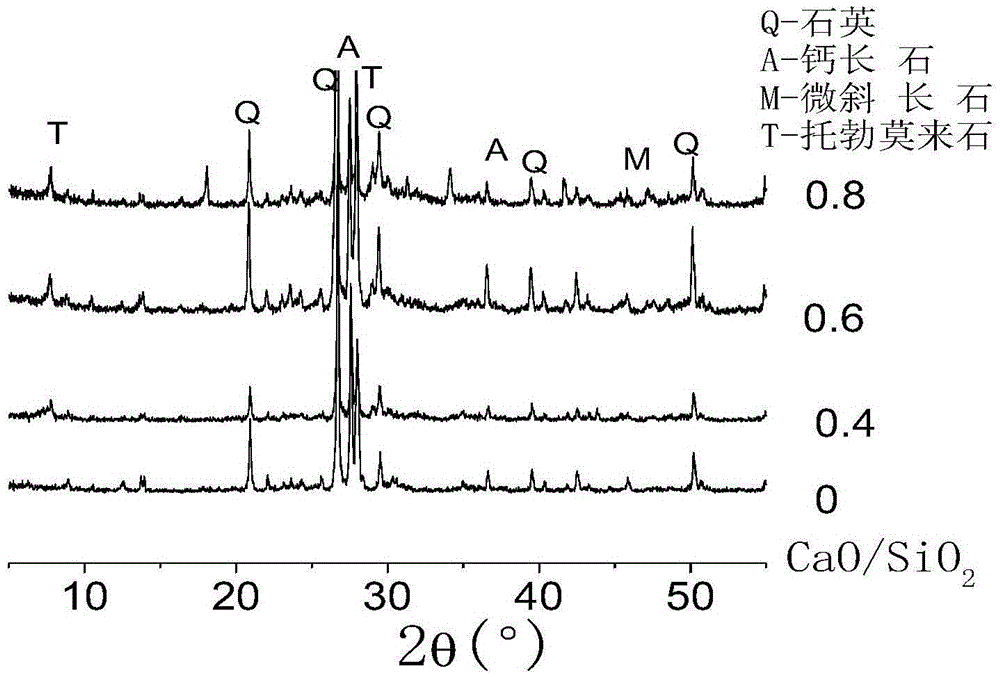

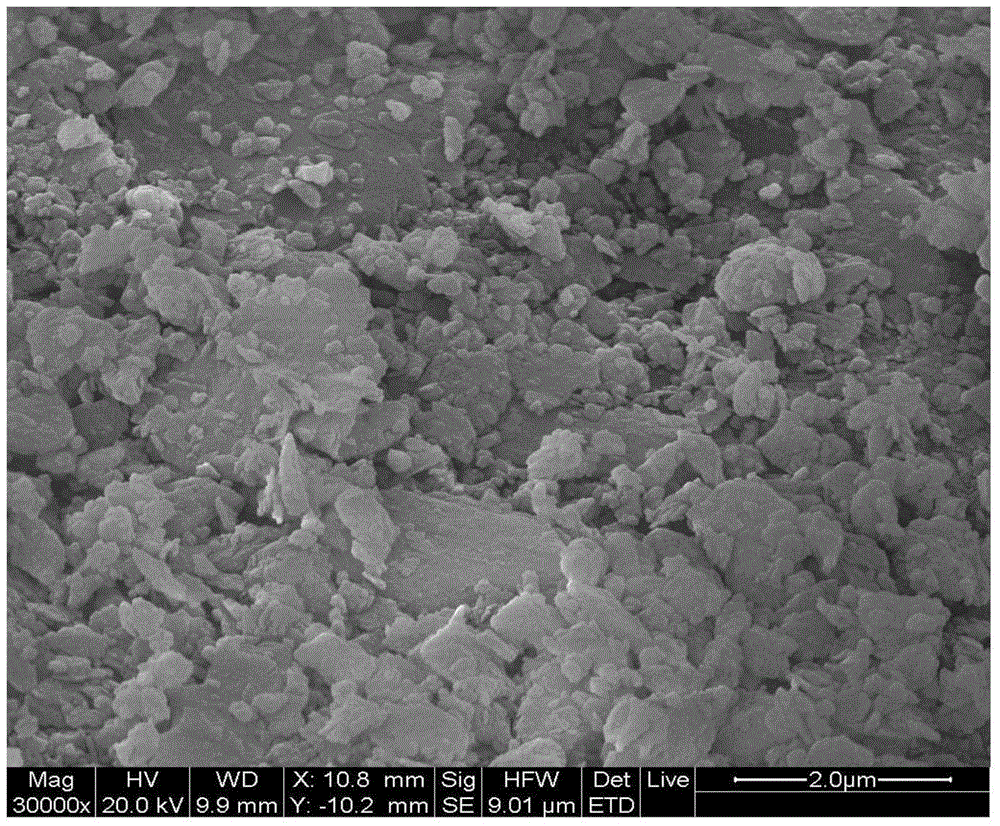

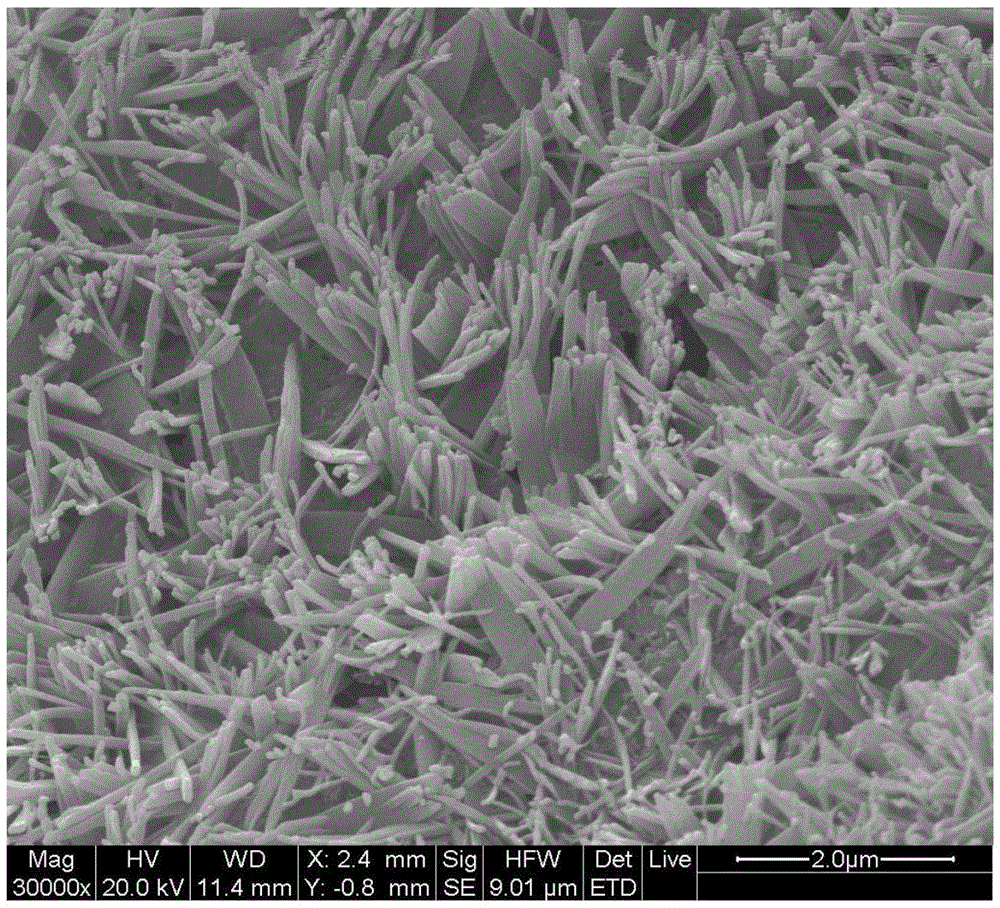

[0025] Firstly, river silt was selected (collected from the Zhengzhou section of the lower reaches of the Yellow River, in which SiO 2 46.8%; Al 2 o 3 20.5%) as the main raw material. Select slough (analytically pure, provided by China Sinopharm Reagent Co., Ltd.) as auxiliary raw material, mix above-mentioned main raw material and auxiliary raw material, get different CaO / SiO in the embodiment 1-5 as shown in table 1 2 Mix the main raw materials and auxiliary raw materials in proportion, and then add water to the above-mentioned mixed material. The amount of water added is 10% of the mixed material mass. After stirring evenly, mold it under 30MPa pressure to obtain length×width×height= 40×15×15mm mixture layer, take the mixture layer as a formed test block, put it into a hydrothermal reaction kettle, and obtain a humidity-regulating effect after 12 hours of hydrothermal treatment at a temperature of 200°C and a pressure of 1.5MPa. porous moisture-regulating material. The ...

Embodiment 6-8

[0029] Preparation of sepiolite modified river silt humidity control material method is as follows: first select main raw material river silt, select auxiliary raw material slaked lime (analytically pure, provided by China National Pharmaceutical Reagent Co., Ltd.), modified raw material sepiolite (provided by Hunan Provided by Hongyan Sepiolite Co., Ltd., Xiangtan County, Province), above-mentioned main raw material and auxiliary raw material are mixed, add the water of 10% of mixture quality, add the water that accounts for its quality 10% in modified raw material sepiolite, then mix The upper layer of the material is paved with sepiolite to form two layers, and CaO / SiO is selected 2 The ratio is 0.8, and the amount of sepiolite is shown in Table 2; it is formed under a pressure of 30 MPa; the formed test block is placed in a hydrothermal reactor, and the temperature is 200 ° C, and the pressure is 1.5 MPa. Saturated steam pressure hydrothermal treatment for 12 hours After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com