Integrated oil and gas reservoir protection tool assembly

A technology for oil and gas reservoirs and protection tools, applied in wellbore/well components, earthwork drilling, construction, etc., can solve the problems of poor safety and effectiveness, complex processing, and great difficulty in workover processing, etc., to achieve convenient Effects of operation, difficulty reduction, and protection from contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical solution of the present invention more clearly understood, the present invention will be described in detail below in conjunction with the accompanying drawings.

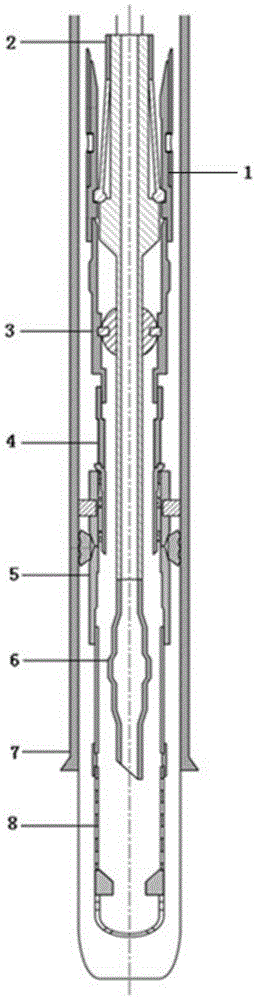

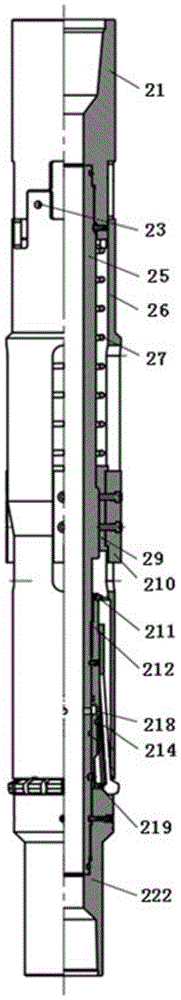

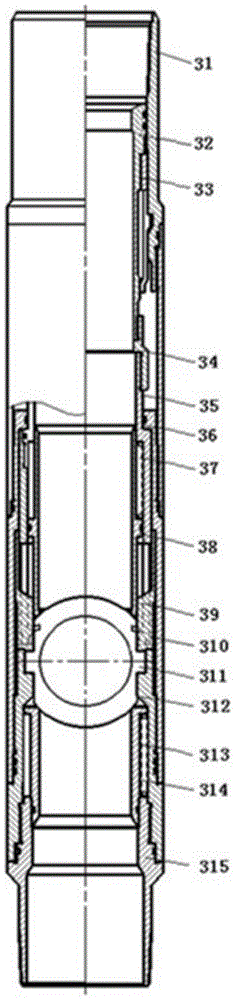

[0028] The integrated oil and gas reservoir protection tool assembly of the present invention includes a work cylinder 1 , a running tool 2 , a formation isolation valve 3 , a connection tool 4 , a suspension packer 5 , and a switch tool 6 .

[0029] figure 1 It shows the installation situation of the integrated oil and gas reservoir protection tool assembly of the present invention in the casing.

[0030] refer to figure 1 , the installation situation in the figure is divided into three layers, the outermost layer is the casing 7; the middle layer is the working cylinder 1, the formation isolation valve 3, the connection tool 4, and the suspension packer 5 installed in the casing 7 in sequence And the screen pipe 8 connected to the hanging packer 5; the innermost layer is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com