A multifunctional hydraulic safety device for oil pipe

A safety device and multi-functional technology, applied in the direction of wellbore/well valve device, drill pipe, casing, etc., can solve the problems of poor safety performance, long time, cumbersome operation, etc., and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

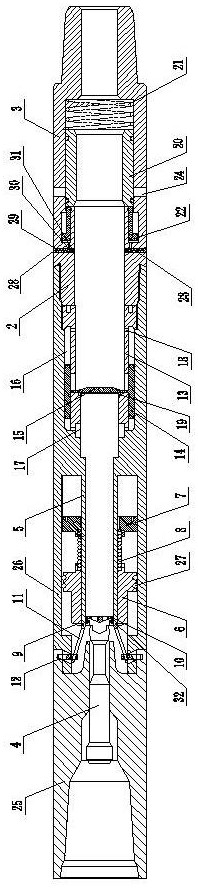

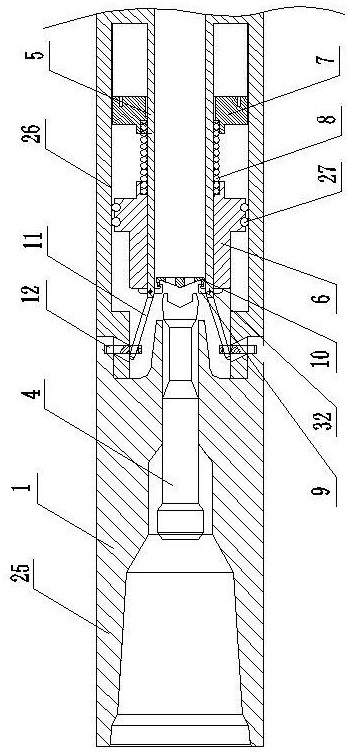

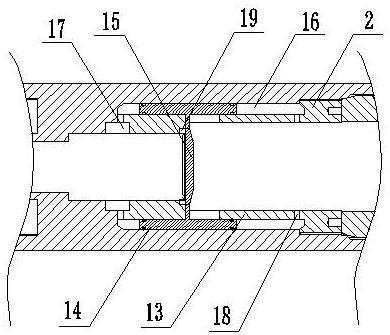

[0015] A oil pipe multifunctional hydraulic safety device of the present invention is composed of a discarding pipe section 1, a pressure equalizing pipe section 2 and a pressure relief pipe section 3. The discarding pipe section 1 is composed of an upper pipe section 25 and a lower pipe section 26 connected internally and externally. The upper pipe section 25 The port is connected with the lower part of the last section of the oil pipe. A hydraulic impact hammer 4 with clearance fit is provided on the axis of the upper inner cavity of the upper pipe section 25, and an inner cylinder 5, the inner cylinder 5 and the lower pipe section are provided on the axis of the lower section 26. The sliding sleeve 6 is fit in the gap between the annular gaps between 26, and a thrust spring 8 is embedded between the lower end of the sliding sleeve 6 and the limit seat 7, and a lock hook 9 and a lock catch 10 are connected to the upper end of the sliding sleeve 6. Buckle the relative lock hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com