Starting method of small-radius curve tunnel

A technology of small-radius curves and tunnels, which is applied in the origination field of small-radius curves tunnels, can solve the problems that the facilities are easily stuck by the segments, unable to originate in a straight line, and the space of the origination shaft is too small to install the reaction frame, etc., to achieve Significant comprehensive benefits, simple structure and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

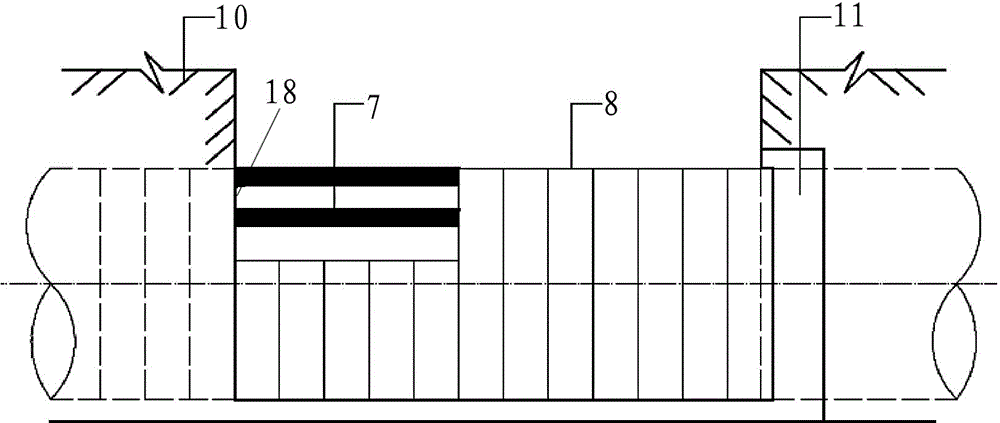

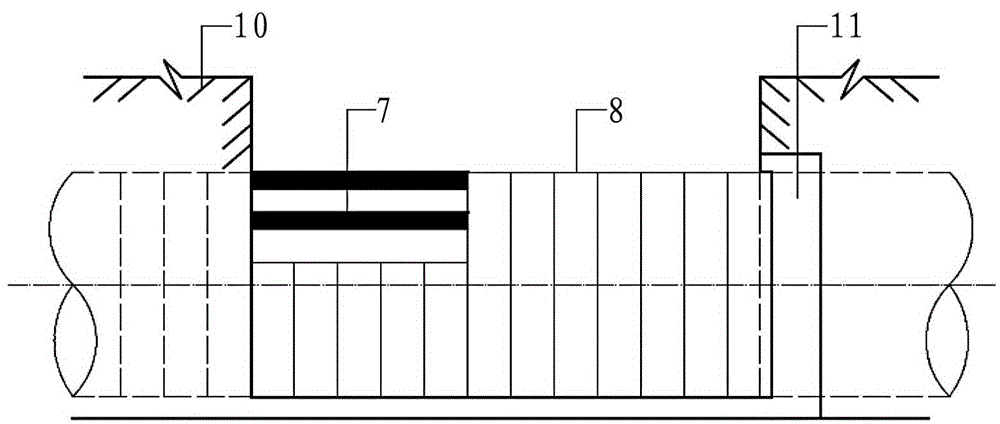

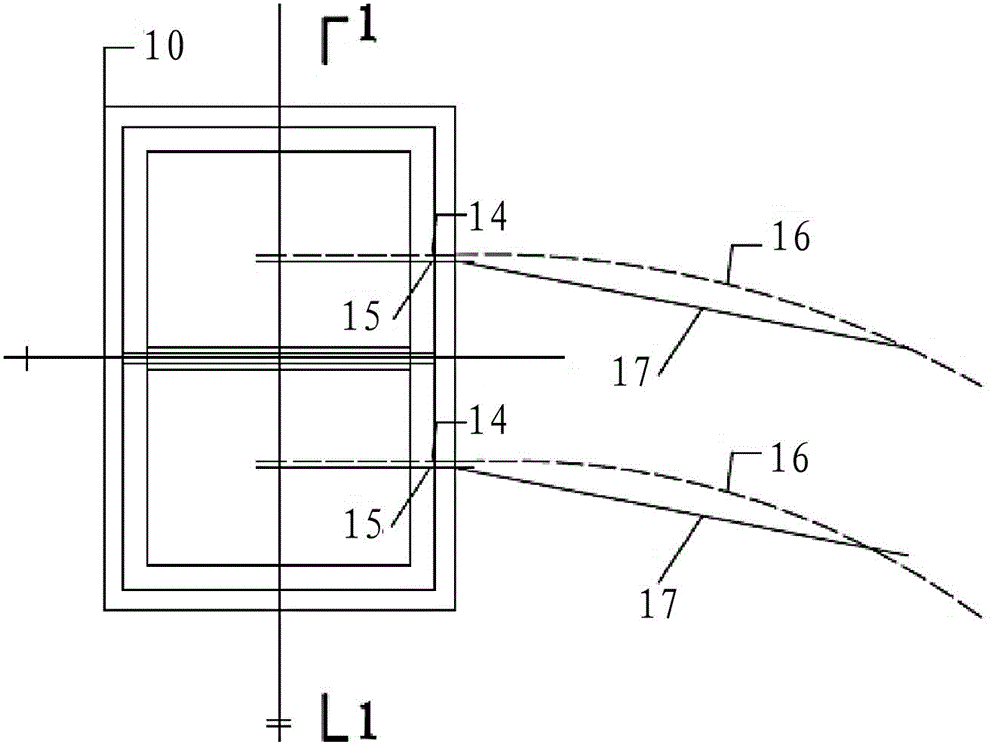

[0028] Such as figure 1 , Figure 5 , Figure 6 As shown, 1—shield machine, 2—cutter head, 3—front shield, 4—middle shield, 5—tail shield, 6—trolley, 7—steel pipe support, 8—segment (negative ring segment), 9—shield shell, 10—starting shaft, 11—starting portal, 12—segment positioning pad, 13—guide rail, 14—centerline of portal, 15—centerline of launching frame, 16—design tunnel center Curve, 17—Shield Tunneling Centerline

[0029] Such as figure 2 , image 3 As shown, the present invention is a method for starting a small-radius curved tunnel, comprising the following steps:

[0030] (1) Put the shield machine 1 from the launch shaft 10 into the formed tunnel and assemble the shield machine 1 in the launch shaft 10;

[0031] (2) Design the tunnel center curve at the portal 11 where the tunnel and the originating shaft 10 intersect, and the center line of the line to be perpendicular to the portal 11; determine the angle between the shield machine 1 and the normal line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com