A mechanical seal conforming to ansi standard pump cavity

An ANSI standard, mechanical seal technology, used in mechanical equipment, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of difficult seal design, narrow cavity for installing seals, etc., to achieve compact structure, radial Small size, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

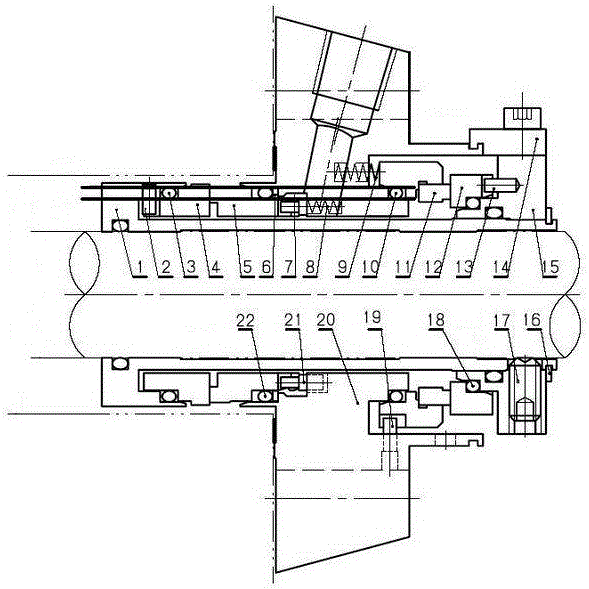

[0018] Such as figure 1 , 2 As shown, the present invention is a mechanical seal conforming to the ANSI standard pump cavity. The shaft sleeve 1 is fitted with an end cover 20, and the two sides of the end cover 20 are respectively equipped with a medium side seal and an atmosphere side seal fitted on the shaft sleeve 1; The medium side seal includes a medium side rotary ring 4, a medium side compensation ring 5, a push ring 7, and a medium side spring 8 installed on the shaft sleeve 1 in sequence. The medium side rotary ring 4 is in contact with the sealing surface of the medium side compensation ring 5 Fitting, the transmission pin 2 is connected between the medium side rotating ring 4 and the shaft sleeve 1, and a seal 3 is installed between the two, and the medium side compensation ring 5 and the push ring 7 are both located in the end cover 20 , the medium side compensating ring 5 is supported by the push ring 7 and anti-rotation, the spring force acts on the medium side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com