Fan assembly and nozzle used for same

A technology of fan components and nozzles, applied in jet pumps, liquid volumetric machinery, pump devices, etc., can solve problems such as wear, nozzles that cannot provide sufficient friction, and loose sliding connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

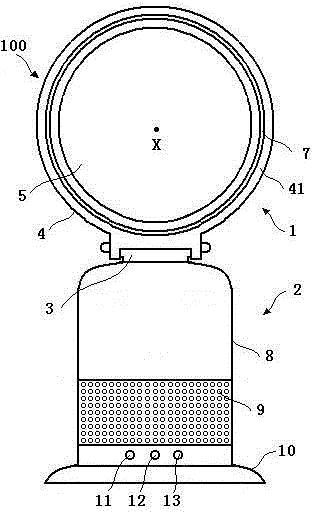

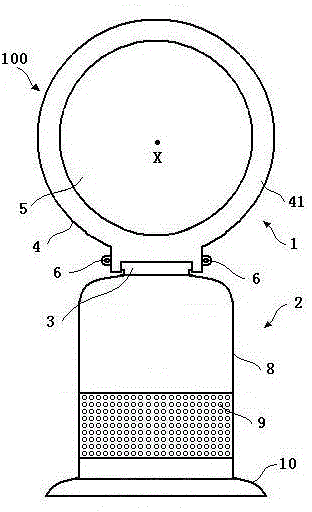

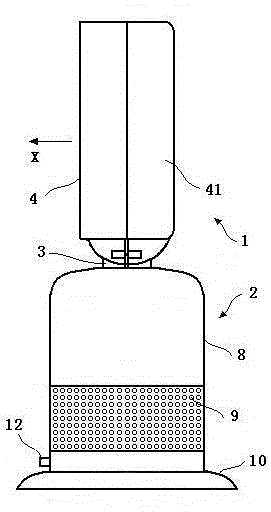

[0044] Figure 1 is a schematic view of the fan assembly of the present invention viewed from the front of the device, figure 2 and image 3 Respectively are the rear view and the side view of the fan shown in Fig. l. From Figure 1 to Figure 3 It can be seen from the figure that the fan 100 includes a base 2 , a nozzle 1 and an adjustment mechanism 6 located on the base 2 . The base 2 includes a lower base 10 and an upper base 8 positioned on the lower base 10. The upper base 8 includes an air inlet 9 and a plurality of buttons 11, 12 and 13 operable by the user. The air inlet 9 is formed on the upper base. in the form of a plurality of holes in the seat housing. Air outside the fan is sucked into the upper base 8 through the air inlet 9 .

[0045] Figure 4 is a schematic diagram of the nozzle of the fan shown in Figure 1, Figure 5 and Figure 6 They are the side view and exploded view of the nozzle of the fan shown in Fig. l respectively. From Figure 4 to Figure 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com