Tightening deformation locking bolt

A technology of special-shaped bolts and bolts, which is applied in the direction of bolts, threaded fasteners, locking fasteners, etc., which can solve the problems of difficult removal and achieve practical adaptability, good adaptability, and good locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

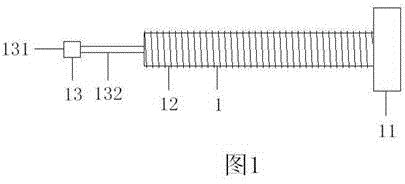

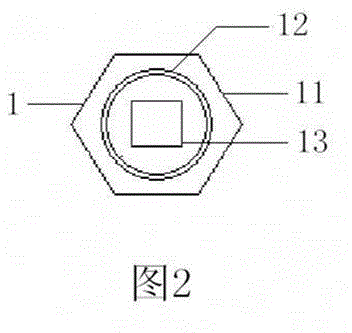

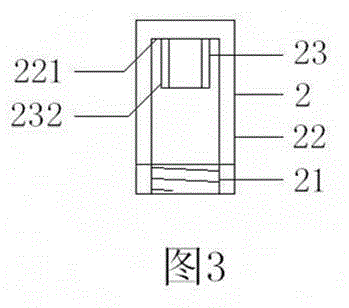

[0110] Such as Figure 1-21 As shown, tighten the deformed locking bolt, which consists of special-shaped bolt 1, cap nut 2, rectangular kit 3, and gasket 4. One end of the special-shaped bolt 1 is the head 11, the other end is the fixed rod 13, and the middle is the outer The threaded screw rod 12 has a nut 21, a cover body 22, and a fixing hole 23 on the cap nut 2, and a gasket 4 is arranged between the special-shaped bolt 1 and the cap nut 2 to separate each other; the cap body 22 and the nut 21 on the cap nut 2 Connected as a whole, the inner top surface 221 of the cover body 22 has a fixing hole 23, and the inner height of the cap nut 2 is greater than the length of the fixing rod 13. When the fixing rod 13 passes through the nut 21 to the fixing hole on the inner top surface 221 of the cover body 22 23, the screw rod 12 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com