Centrifugal automatic lubrication bearing protection system

An automatic lubrication and protection system technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve problems such as shortened life, high temperature, and impact on product life, and achieve extended service life, wear and heat Effects of reduction, broad market and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

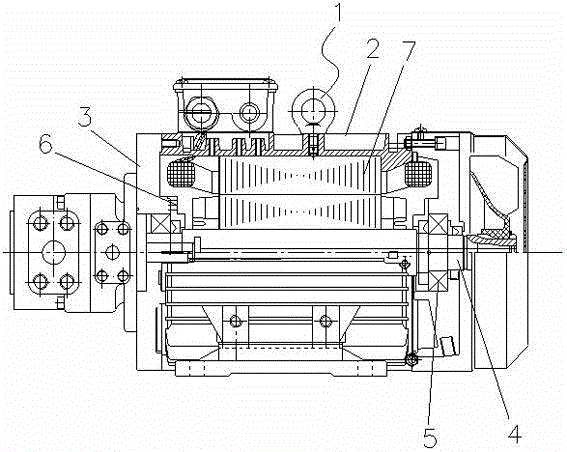

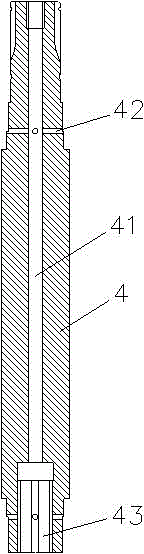

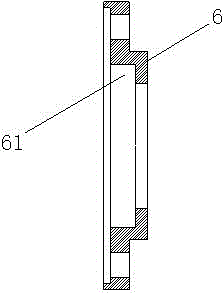

[0014] Embodiment one: if Figure 1~3 As shown, a motor applying this system includes a cylinder body 2, and cylinder heads 3 are arranged at both ends of the cylinder body 2, grooves are arranged on the inner end surface of the cylinder head 3, and the cylinder body 2 A rotating shaft 4 is arranged inside, and a rotor 7 is mounted on the rotating shaft 4, and the two ends of the rotating shaft 4 are respectively installed in the groove of the cylinder head through a bearing 5, and the two ends of the rotating shaft 4 are respectively sleeved with The bearing rear cover 6 against the bearing 5, a liquid storage chamber 43 is arranged on one end surface of the rotating shaft 4, a through hole 41 along the axial center line is arranged in the rotating shaft 4, and the two ends of the rotating shaft 4 The side walls are also respectively provided with through holes 42 communicating with the liquid storage chamber 43 and the through hole 41 , and the through holes 42 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com