A through-flow food drying device with two-way commutation function

A technology of two-way commutation and drying device, applied in drying, drying machine, drying gas arrangement and other directions, can solve problems such as low drying efficiency and energy waste, and achieve simple drying box, uniform temperature and consistent color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention shall not be limited in any way, and any changes or improvements made based on the teaching of the present invention shall fall within the scope of protection of the present invention.

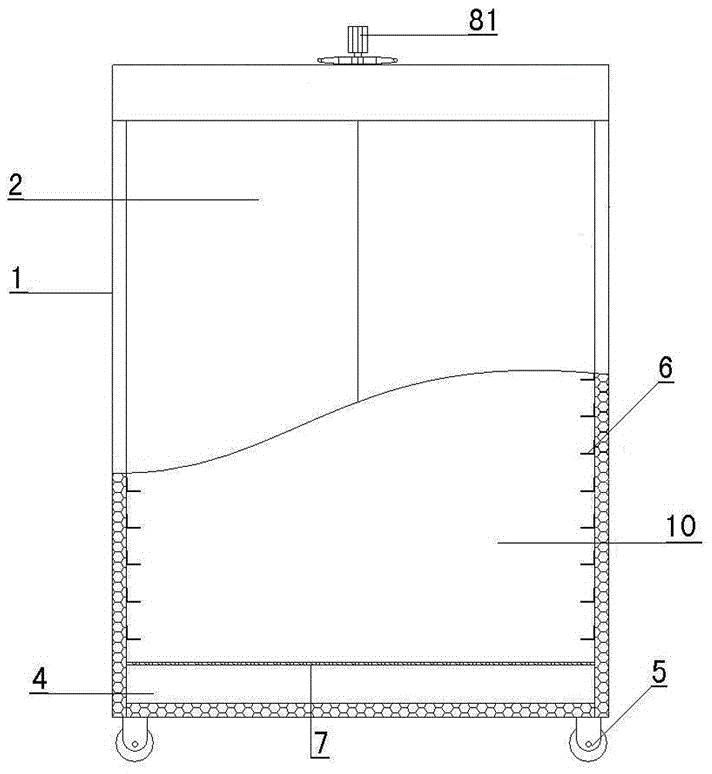

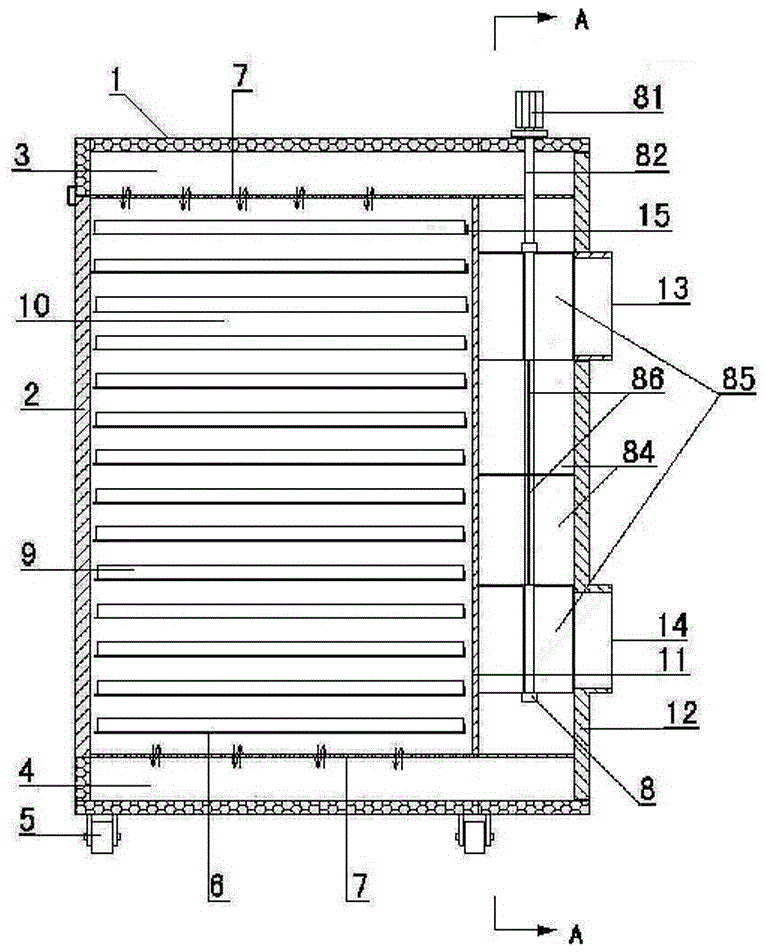

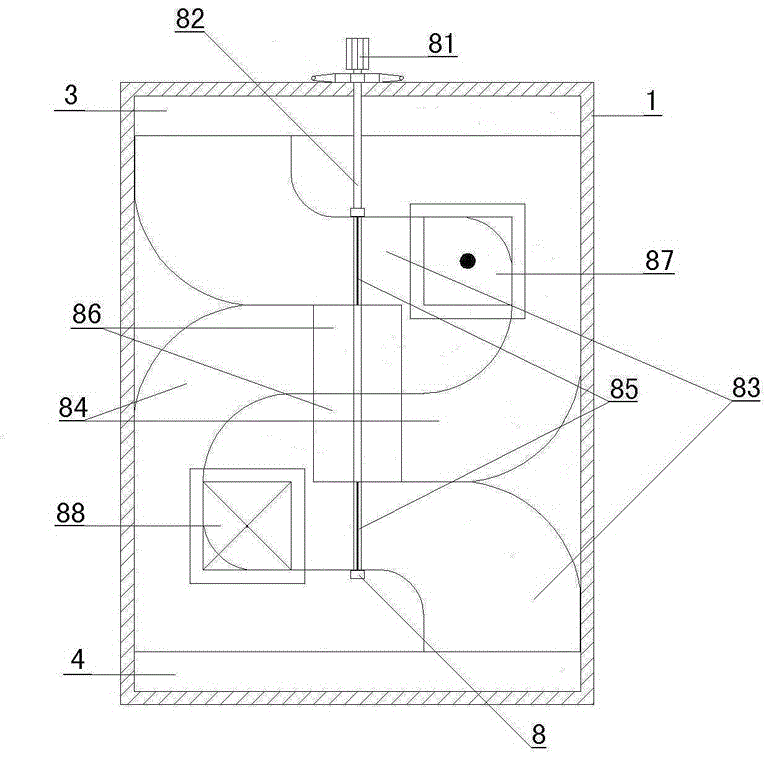

[0011] Such as Figure 1~3 As shown, the present invention includes a drying box 1 and a hot air pipeline. A drying chamber 10 is arranged in the drying box 1. The two sides of the drying chamber 10 are symmetrically provided with a storage guide groove 6, and the storage guide groove 6 is provided with The material tray 9, the top and bottom of the drying chamber 10 are respectively equipped with air distribution plates 7 to form the upper circulation air passage 3 and the lower circulation air passage 4, and a partition 11 is arranged on one side of the drying chamber 10 to form a hot air pipeline. A two-way reversing device 8 is set in the hot air pipeline, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap