Reflective flame retardant ribbon for micro-prism and manufacturing method of reflective flame retardant ribbon

A manufacturing method and technology of microprism, applied in chemical instruments and methods, optics, optical components, etc., can solve problems such as inability to meet the needs of fire safety itself, increase investment in production costs, and inability to play reflective warnings to avoid Instability phenomenon, avoid pollution damage, the effect of excellent reflective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

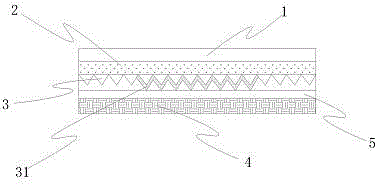

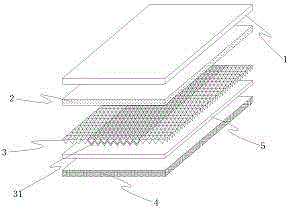

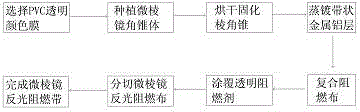

[0037] refer to Figure 1 to Figure 2 , the embodiment of the present invention discloses that a microprism reflective flame retardant tape comprises a flame retardant layer 1, a substrate layer 2, a microprism resin pyramid layer 3 and a flame retardant cloth layer 4, the flame retardant Layer 1 is composed of a colorless flame retardant with high transparency and clarity, and the flame retardant layer 1 is coated on the upper surface of the base layer 2; the microprism resin pyramid layer 3 is planted on the base layer 2 The lower surface, the lower surface of the microprism resin pyramid layer 3 is provided with a metal electroplating layer 31, and the metal electroplating layer 31 is an electroplated aluminum layer, and the metal electroplating layer 31 is only located on the microprism resin pyramid Body layer 3 is in the middle position on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com