Acoustic control method of active structure of sealed cavity

A closed cavity, active structure technology, applied in the direction of sound-producing instruments, instruments, etc., can solve the problems of poor system versatility, inability to generalize, and low robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

[0058] The present invention provides a method for controlling active structure-borne sound in a closed cavity, the method comprising the following steps:

[0059] Step 1: Decompose the closed cavity structure-acoustic control problem;

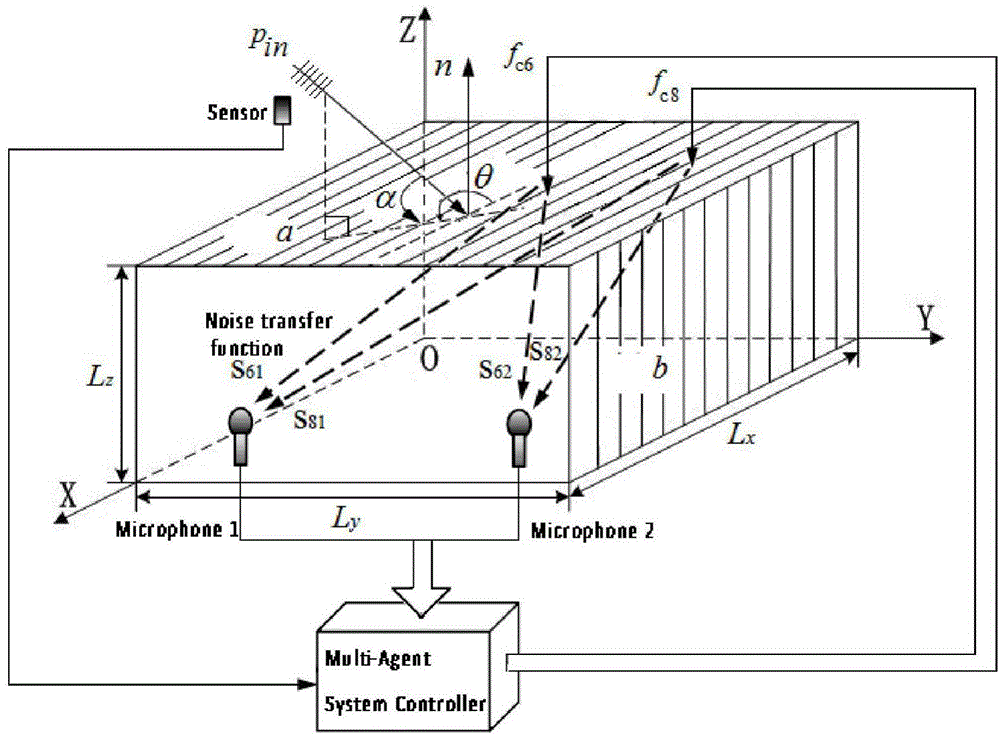

[0060] The noise in the closed cavity is dominated by the structural mode of the elastic plate excited by the primary, that is, the eigenfrequency of the elastic plate and the acoustic mode of the cavity and the eigenfrequency of the cavity, especially when the eigenfrequency of the elastic plate is close to the cavity Strong structure-acoustic coupling will be generated when the characteristic frequency of the cavity is high, causing the peak of the sound pressure in the cavity to appear at this frequency; when the size of the closed cavity is not very large, the cavity noise is mainly dominated by several order structural modes. Wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com