Busbar unit

A technology of bus bars and stators, which is applied to household components, electrical components, electromechanical devices, etc., and can solve problems such as increased conductor resistance and reduced current flowing through the main body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

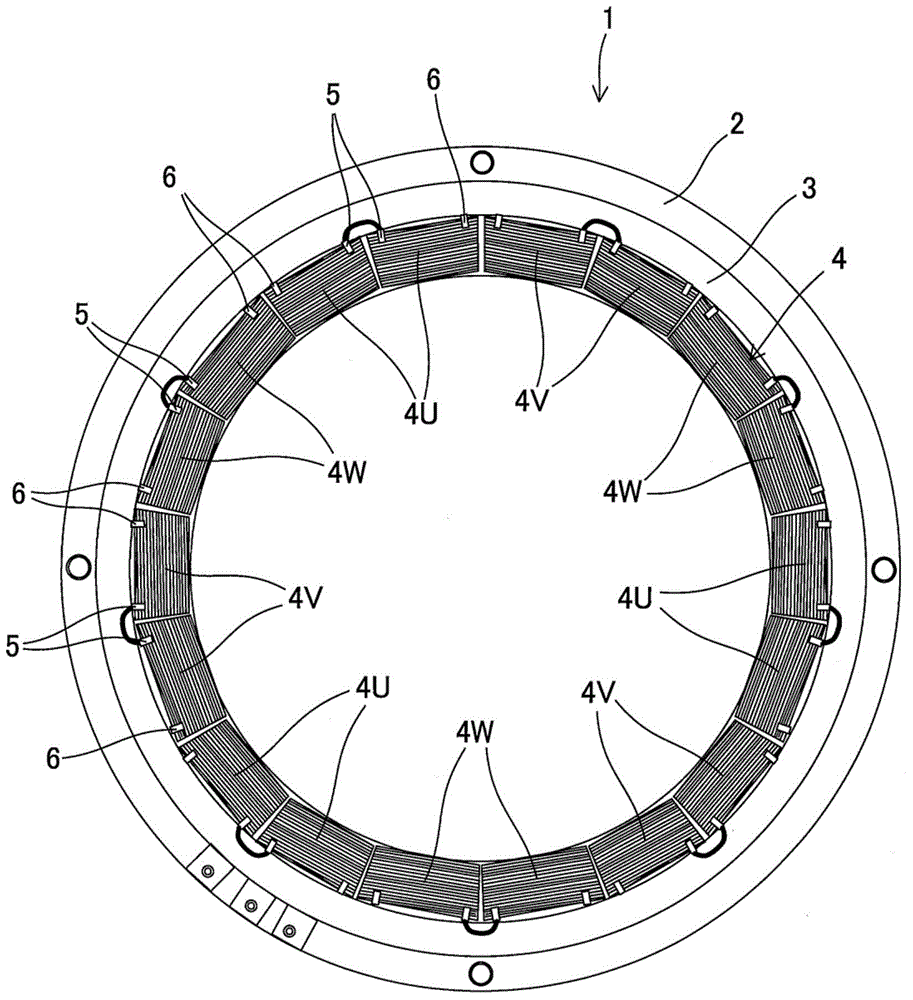

[0016] figure 1 It is a configuration diagram showing a stator 1 constituting a three-phase AC motor.

[0017] A plurality of teeth portions (not shown) are formed on the annular stator core 3 held by the case 2 so as to protrude inward. A copper wire is wound around each tooth portion, and the coil 4 is constituted by the wound wire.

[0018] Eighteen coils 4 are annularly arranged on the stator core 3 along the circumferential direction of the stator 1 . The coils 4 are composed of a U-phase coil 4U, a V-phase coil 4V, and a W-phase coil 4W, and two in-phase coils 4 are arranged at intervals of 120 degrees in the circumferential direction of the stator 1 . Therefore, three sets of one set of U-phase coils 4U, one set of V-phase coils 4V, and one set of W-phase coils 4W are sequentially arranged along the circumferential direction of the stator 1 .

[0019] In adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com