Application method of automatic fractionated water charging device driven by steam turbine

A technology of automatic water addition and steam wheel, applied in the field of kitchen utensils, can solve the problems of wasting ingredients, cracking, wasting time, etc., and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

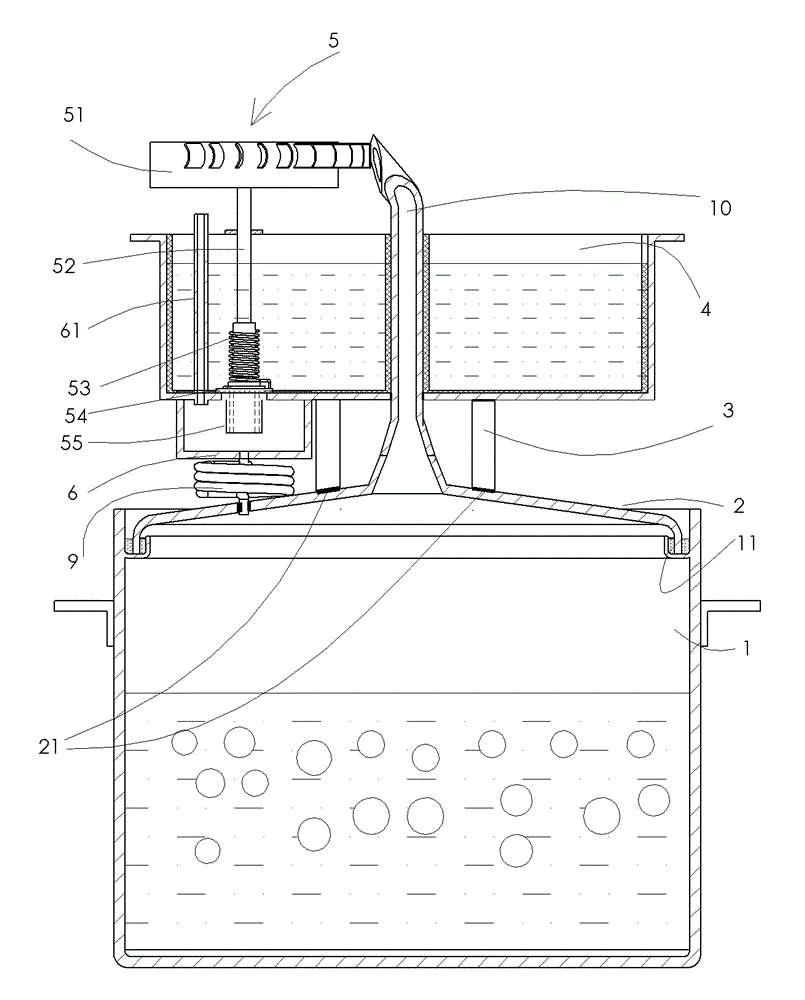

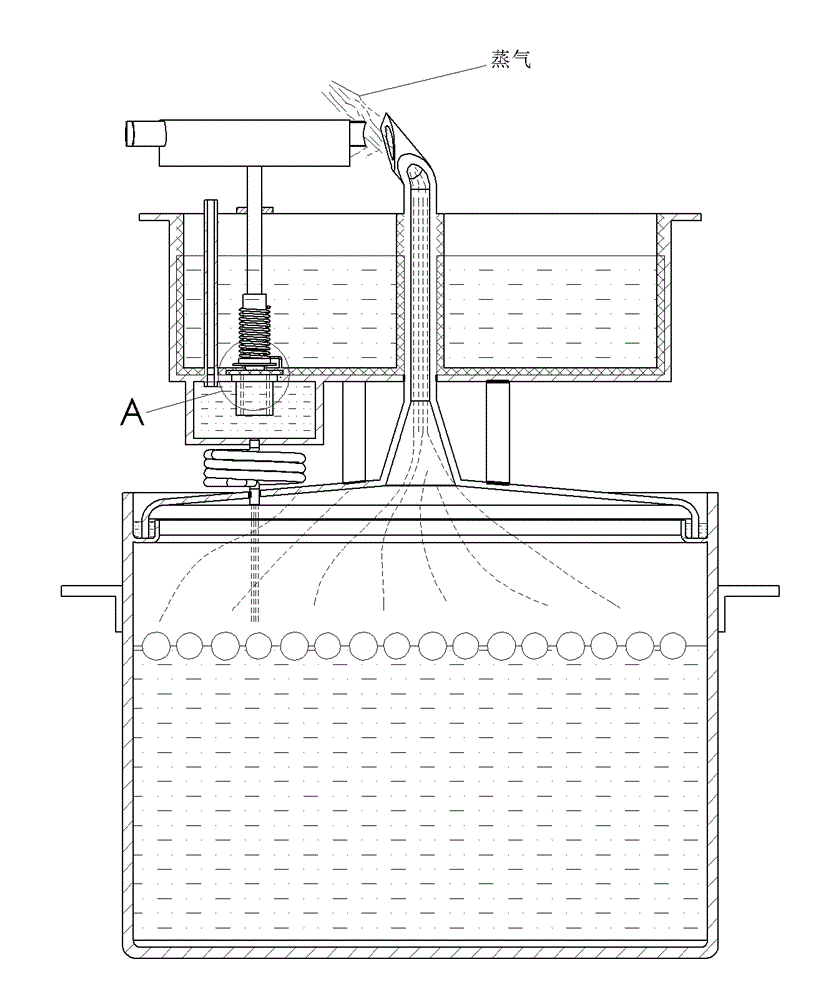

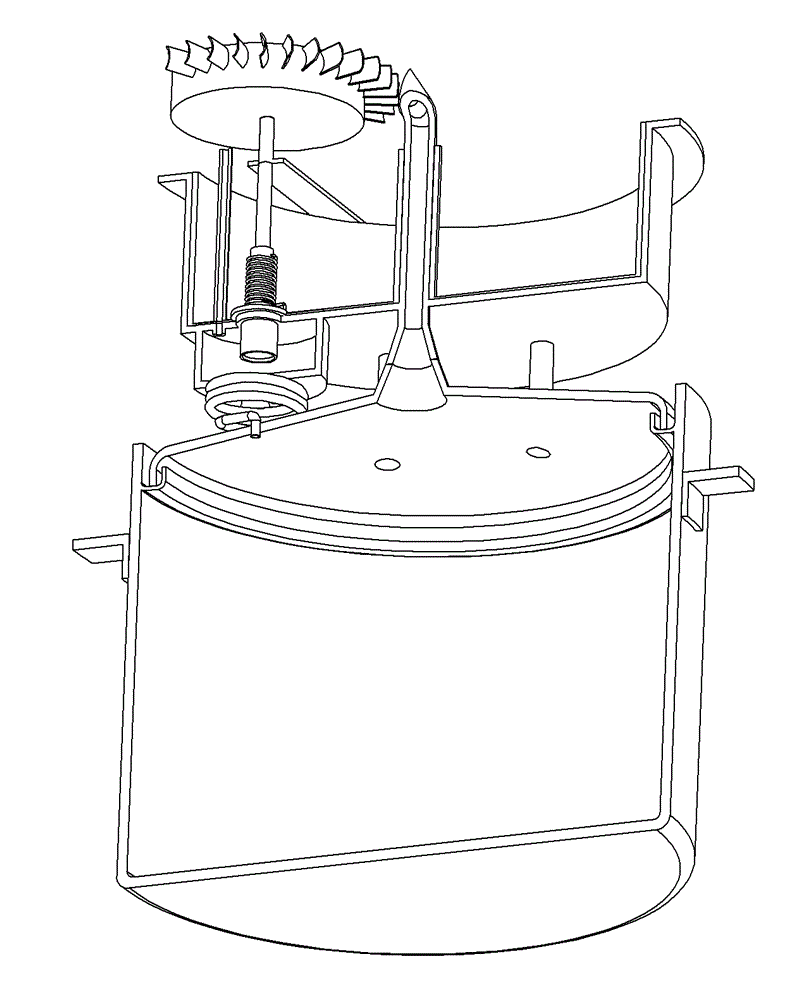

[0028] Embodiment 1, see figure 1 and figure 2 , the present invention is to be provided with water sealing ditch 11 in the pot 1 of boiled glutinous rice balls, and adds automatic water-adding mechanism; Basin 6, air jet pipe 10; the pot cover 2 is connected to the water container 4 through a plurality of columns 3, the lower end of the pot cover 2 is inserted into the water sealing groove 11 in the pot 1, and the water sealing groove 11 is added for sealing water (the water used for sealing is usually normal temperature water, of course water with high temperature or low temperature is also acceptable); the water container 4 is provided with normal temperature water and steam wheel assembly 5; the steam wheel assembly 5 includes Impeller 51, impeller shaft 52, torsion spring 53, water inlet screw rod 54, water inlet nut 55; impeller 51, impeller shaft 52, water inlet screw rod 54, water inlet nut 55 are sequentially connected; connected, the other end is fixedly connected...

Embodiment 2

[0058] In Embodiment 2, the sealing method of the pressure cooker sealing ring (because it is the prior art, not drawn) can be used to replace the water sealing method in Embodiment 1. That is, a rubber sealing ring is set between the pot cover and the pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com