Cu-containing molecular sieve adsorbent and preparation method thereof

A molecular sieve and adsorbent technology, applied in the field of Cu-containing molecular sieve adsorbent and its preparation, can solve the problems of low adsorption capacity, poor regeneration stability, low purification accuracy of the adsorbent, etc., and achieve the effect of good regeneration and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

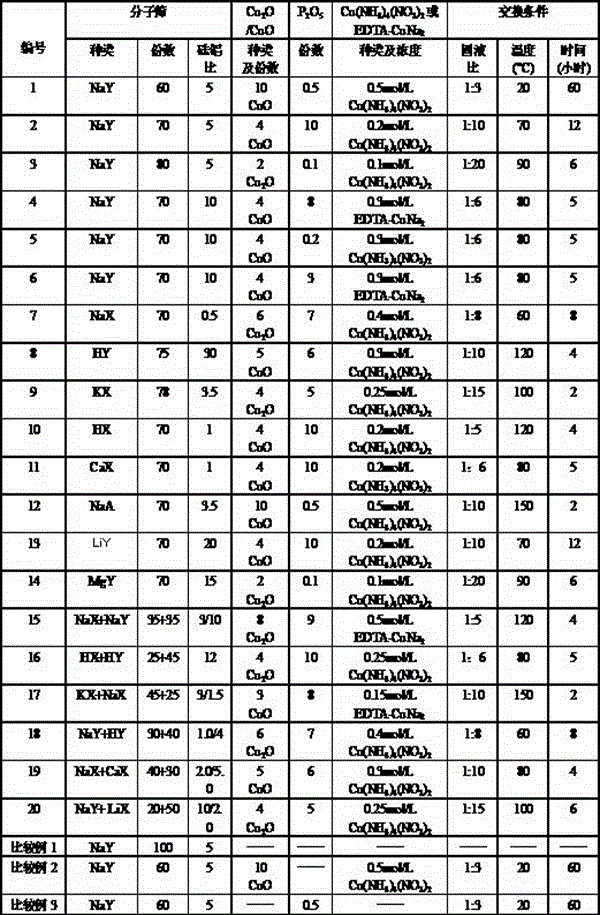

Examples

Embodiment 1

[0026] The preparation process of the ion-exchange modified NaY molecular sieve adsorbent containing CuO and P is as follows. First, accurately weigh

[0027] 10 g NaY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, Cu(NO 3 ) 2 solution 30 ml, continuously drop NH in the above solution 3 h 2 O, added NH 3 h 2 The amount of O species is Cu(NO 3 ) 2 Add according to the amount of 4:1, that is, 0.5mol of Cu(NO 3 ) 2 Need to add 2mol of NH 3 h 2 O, forming Cu(NH 3 ) 4 (NO 3 ) 2 solution. Thereafter, 86% by weight H was added dropwise continuously 3 PO 4 solution (density 1.6 g / ml), make H 3 PO 4 The molar concentration is 0.1mol / L. Add the accurately weighed NaY molecular sieve powder to the above 30 ml Cu(NH 3 ) 4 (NO 3 ) 2 And in the solution containing P, that is, according to the condition that the solid-liquid ratio is 1:3, at 20 o C, fully stirred, exchanged for 60h. Filter and rinse with deionized water. Repeat the ab...

Embodiment 2

[0030] The preparation process of the ion-exchange modified NaY molecular sieve adsorbent containing CuO and P is as follows. First, accurately weigh 11 g of NaY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, Cu(NO 3 ) 2 solution 110 ml, continuously drop NH in the above solution 3 h 2 O, added NH 3 h 2 The amount of O species is approximately Cu(NO 3 ) 2 Add according to the amount of 4:1, that is, 0.2mol of Cu(NO 3 ) 2 Need to add 0.8mol of NH 3 h 2 O, forming Cu(NH 3 ) 4 (NO 3 ) 2 solution. Thereafter, 86% by weight H was added dropwise continuously 3 PO 4 solution (density 1.6 g / ml), make H 3 PO 4 The molar concentration is 0.2mol / L. Add accurately weighed 11g NaY molecular sieve powder to the above 110 ml Cu(NH 3 ) 4 (NO 3 ) 2 And in the solution containing P, that is, according to the solid-liquid ratio of 1:10, at 70 o C, fully stirred, exchanged for 12h. Filter and rinse with deionized water. The exchanged molecu...

Embodiment 3

[0033] Cu containing 2 parts by weight 2 The preparation process of the ion-exchange modified NaY molecular sieve adsorbent with O and 0.1 parts by weight of P and 80 parts by weight of NaY is as follows. First, accurately weigh 12 g of NaY molecular sieve raw powder with a silicon-aluminum ratio of 5. Subsequently, Cu(NO 3 ) 2 solution 240 ml, continuously drop NH in the above solution 3 h 2 O, added NH 3 h 2 The amount of O species is approximately Cu(NO 3 ) 2 Add according to the amount of 4:1, that is, 0.1mol of Cu(NO 3 ) 2 Need to add 0.4mol of NH 3 h 2 O, forming Cu(NH 3 ) 4 (NO 3 ) 2 solution. Thereafter, 86% by weight H was added dropwise continuously 3 PO 4 solution (density 1.6 g / ml), make H 3 PO 4 The molar concentration is 0.05 mol / L. Add accurately weighed 8g NaY molecular sieve powder to the above 240 ml Cu(NH 3 ) 4 (NO 3 ) 2 And in the solution containing P, that is, according to the solid-liquid ratio of 1:20, at 90 o C, fully stirred,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com