Glue spraying device and glue spraying method

A technology of spraying glue and glue tank, which is applied to spraying devices, devices that apply liquid to the surface, coatings, etc., can solve the problems of complex cooling device mechanism and increase energy consumption, and achieve lower production costs, lower requirements, and avoidance of The effect of shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

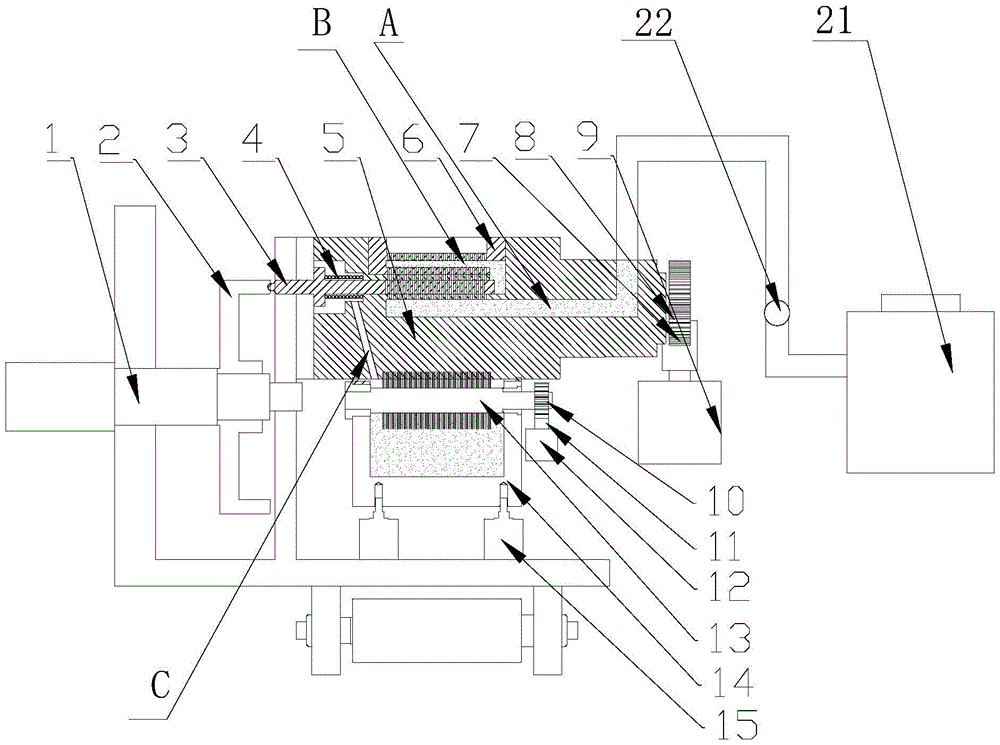

[0039] like figure 2 , image 3 As shown, the glue spraying device of the present invention includes a cam 2, the cam 2 is connected to the left end of the slide bar switch 3, and the right side of the slide bar switch 3 is connected to the compression spring 4;

[0040] The cam 2 rotates under the driving of the transmission shaft 1, and exerts a force to the right on the slide switch 3; the compression spring 4 exerts a force to the left on the slide switch 3; under the joint action of the cam 2 and the compression spring 4, Control the reciprocating linear motion of the slide bar switch 3;

[0041] The slide bar switch 3 is movably set in the glue tank 5, and the glue tank 5 is provided with a glue storage area A, and the glue storage area A is connected to the glue box 21 through the glue delivery pipeline; the glue delivery pipeline is provided with a pump 22;

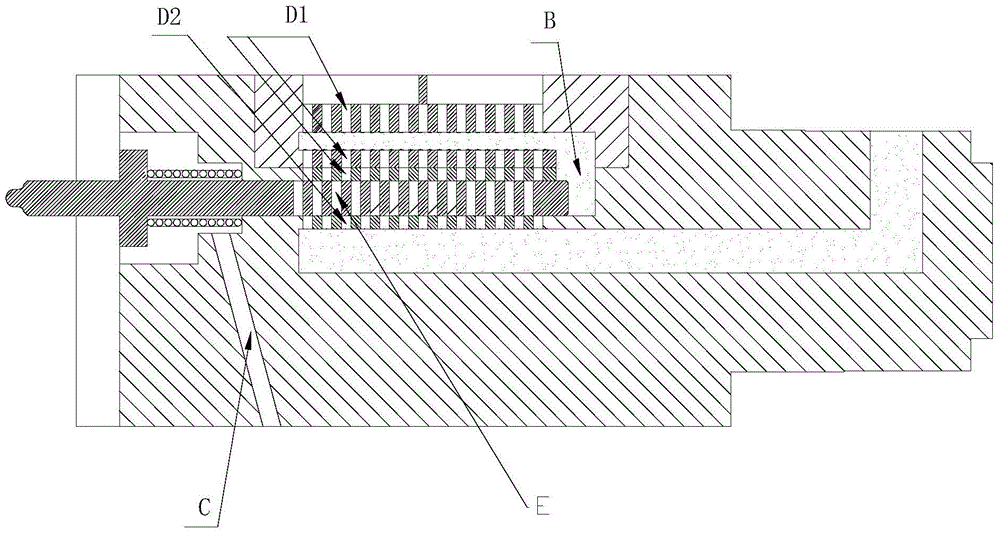

[0042] The upper part of the glue tank 5 is provided with a plurality of upper channels D1 extending longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com