A high-efficiency coal underground gasifier and its construction method

An underground gasification and coal technology, applied in coal gasification, underground mining, construction, etc., can solve problems such as inability to achieve effective coverage of coal resources, stress concentration at the bottom of boreholes, and affecting stable gas output from boreholes, shortening the construction cycle, The effect of balancing gas components and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

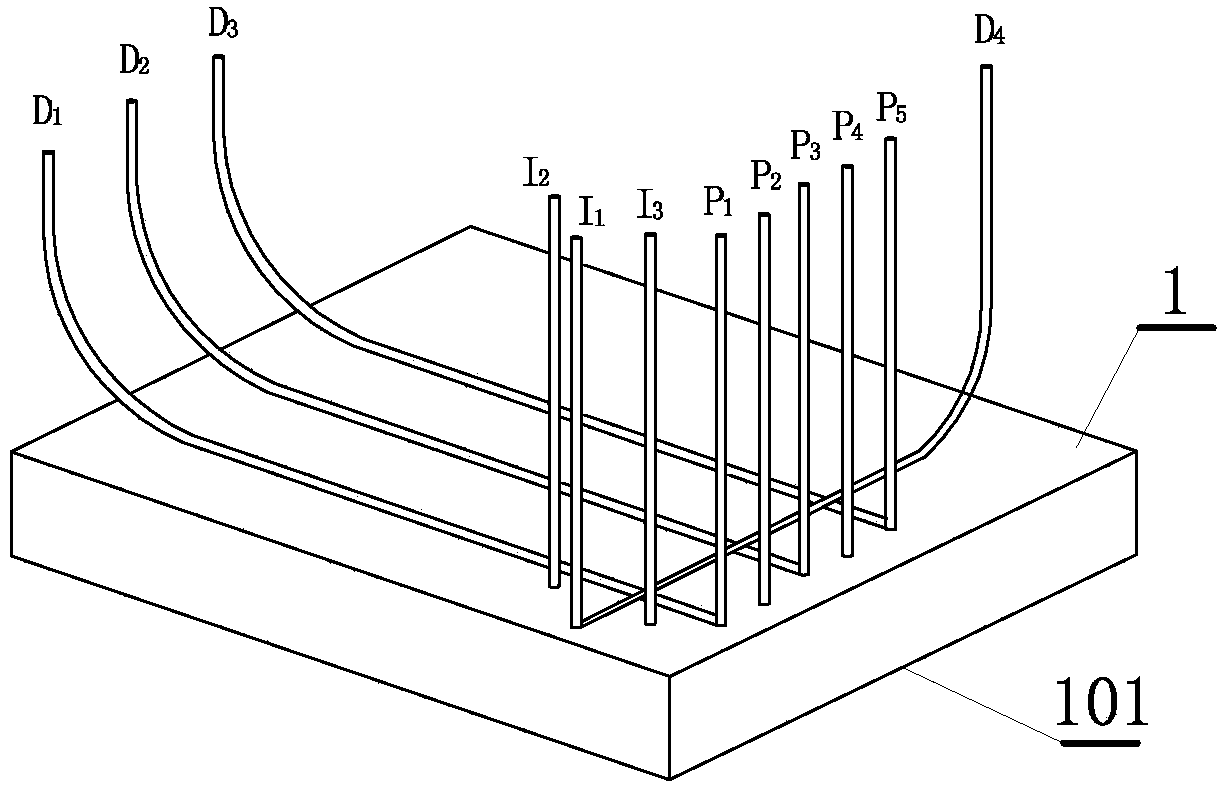

[0024] A high-efficiency coal underground gasifier, such as figure 1 As shown, it includes ignition channel I1, gas collection channel D4, intake channels D1, D2, D3 and gas outlet channels P1, P2, P3, P4, P5 set in a quadrilateral coal seam block 1, wherein the ignition channel is a A vertical downward drilling channel, the ignition channel is arranged in a corner area of the quadrilateral coal seam block, the drilling channel extends into the coal seam and is about 0.5 to 2 m away from the coal seam floor 101, and at least two Auxiliary ignition channels I2, I3, the two auxiliary ignition channels and the ignition channel are in a triangular layout in the corner area, the ignition channel is connected with the two auxiliary ignition channels at the bottom end through the ignition channel gap, and the gas collection channel is at a distance from the coal seam floor. 0.5 to 2m is connected to the ignition channel, and extends horizontally to another corner area adjacent to t...

Embodiment 2

[0030]A method for constructing a high-efficiency underground coal gasifier based on the embodiment 1 is a method of setting an ignition channel, a gas collection channel, an air intake channel and a gas outlet channel in a quadrilateral coal seam block. In the embodiment of the city, therefore, the gas outlet channel is a channel perpendicular to the ground, wherein: the ignition channel is in a corner area of the quadrilateral coal seam block, the inlet of the inlet channel and the outlet of the gas outlet channel are respectively in one row, each row is multiple, one row The inlet of the intake channel and the outlet of an exhaust channel are respectively arranged on two opposite edges of the quadrilateral coal seam block, the gas collecting channel is one, and the gas gathering channel is arranged on the side of the gas outlet channel of the quadrilateral coal seam block and communicates with the ignition channel, wherein, The gas gathering channel is drilled from the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com