Transformer heat dissipation device

A cooling device and transformer technology, which is applied in the field of transformers, can solve problems such as inability to repair and maintain transformer cooling devices, affect the normal performance of cooling oil, and do not have filtering functions, so as to improve heat dissipation, avoid loose parts, and improve purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

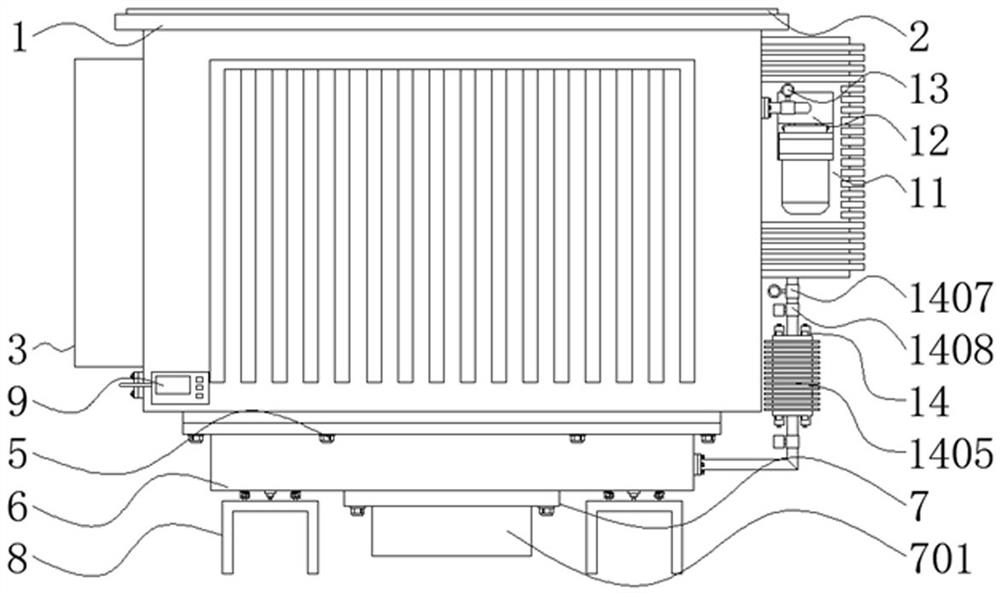

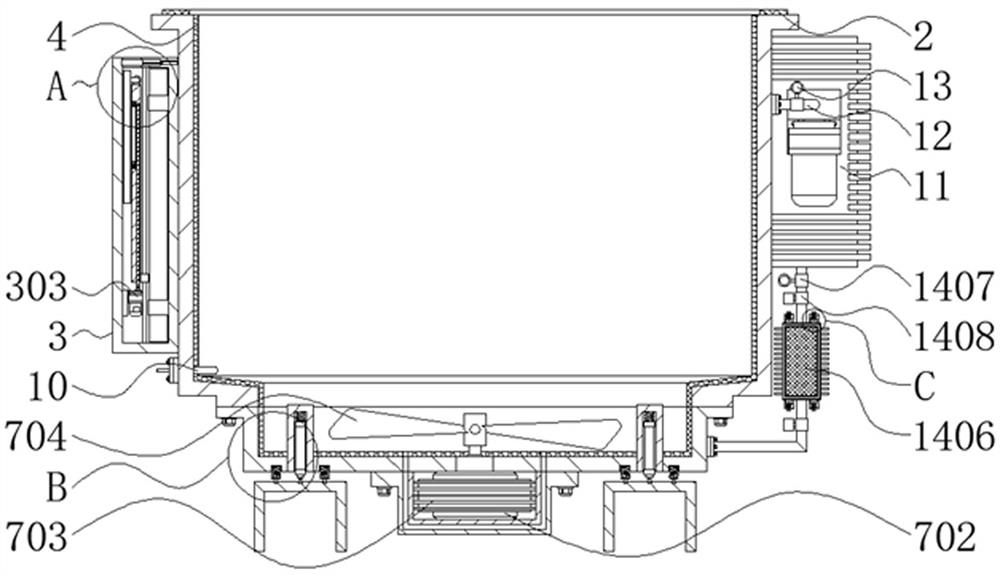

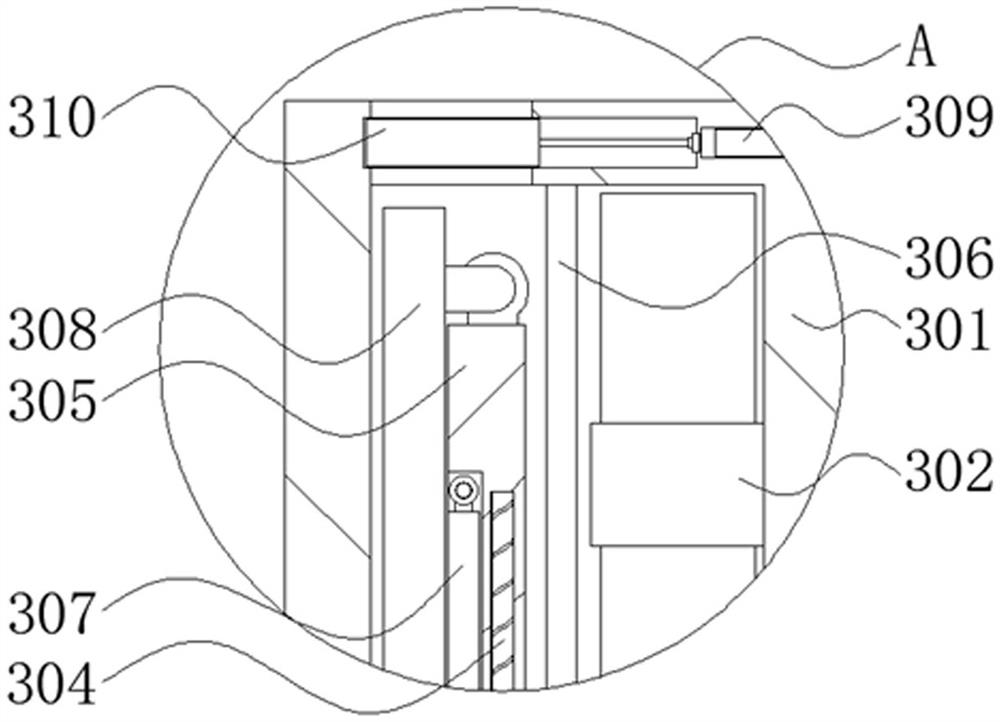

[0025] see Figure 1-3, the present invention provides a technical solution: a heat sink for a transformer, comprising a fin housing 1 and an oleophobic coating 4, a sealing ring 2 is arranged on the outer surface of the fin housing 1, and the outer surface of the fin housing 1 A solar panel lifting assembly 3 is fixed on one side, and the solar panel lifting assembly 3 includes a side housing 301, a battery 302, a micro motor 303, a screw rod 304, a rod body 305, a guide rod 306, a long electric cylinder 307, a solar panel body 308, a miniature Electric cylinder 309 and baffle plate 310, and one side of the inner wall of side casing 301 is fixed with battery 302, and the other side of the inner wall of side casing 301 is provided with micromotor 303, and the top of micromotor 303 is installed with screw rod 304, and The outside of the rod 304 is provided with a rod body 305, and one side of the rod body 305 is provided with a guide rod 306, the micro motor 303 drives the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com