A chicken cage cleaning and disinfection system

A technology for cleaning and disinfecting chicken cages, which is applied in the field of chicken cage cleaning and disinfection systems, and can solve the problems of slow cleaning and disinfection speed and slow cleaning speed of chicken cages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

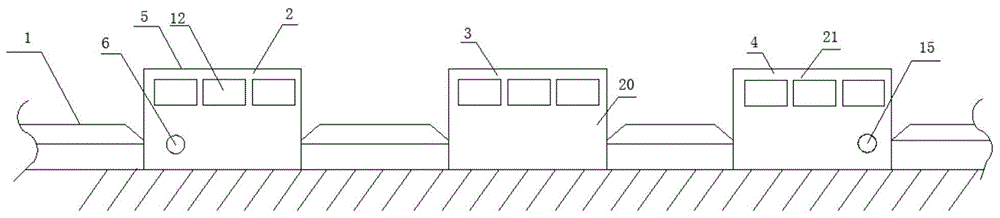

[0024] Embodiment 1: a kind of chicken cage cleaning and disinfection system, its structure is as follows Figure 1-3 shown, including:

[0025] Washing unit 2, soaking unit 3 and sterilizing unit 4, washing unit 2 transmits the chicken cage to soaking unit 3 through the conveying device 1, and soaking unit 3 transmits the chicken cage to the sterilizing unit 4 through the conveying device 1, and completes the chicken cage cleaning and disinfection;

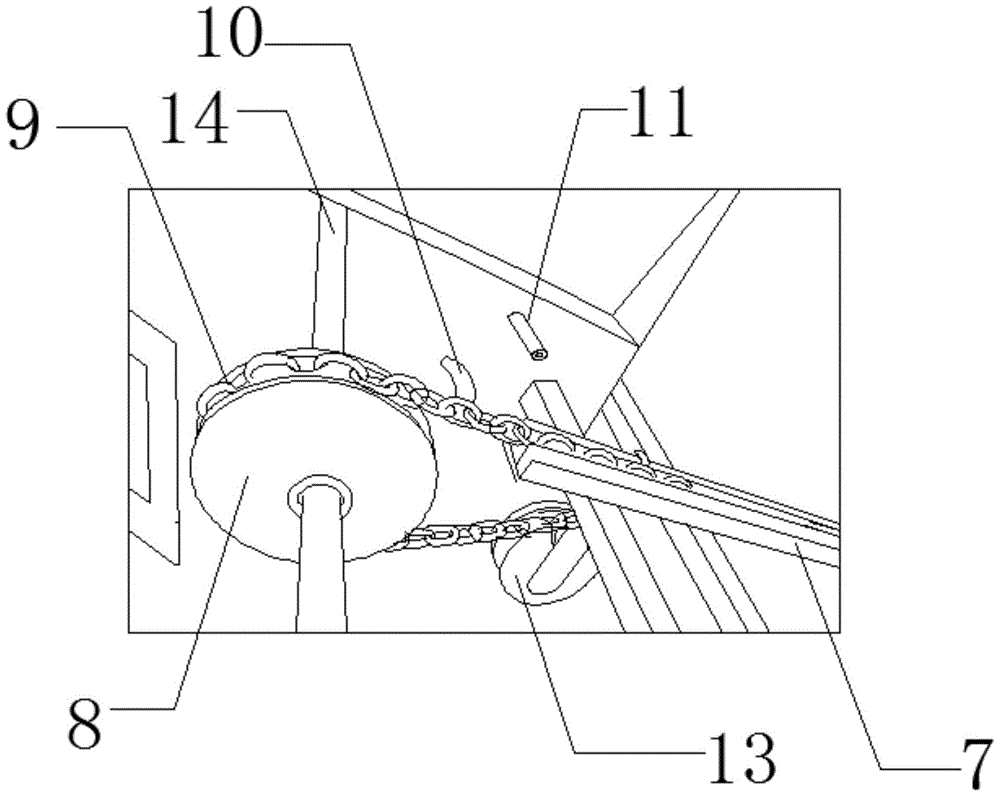

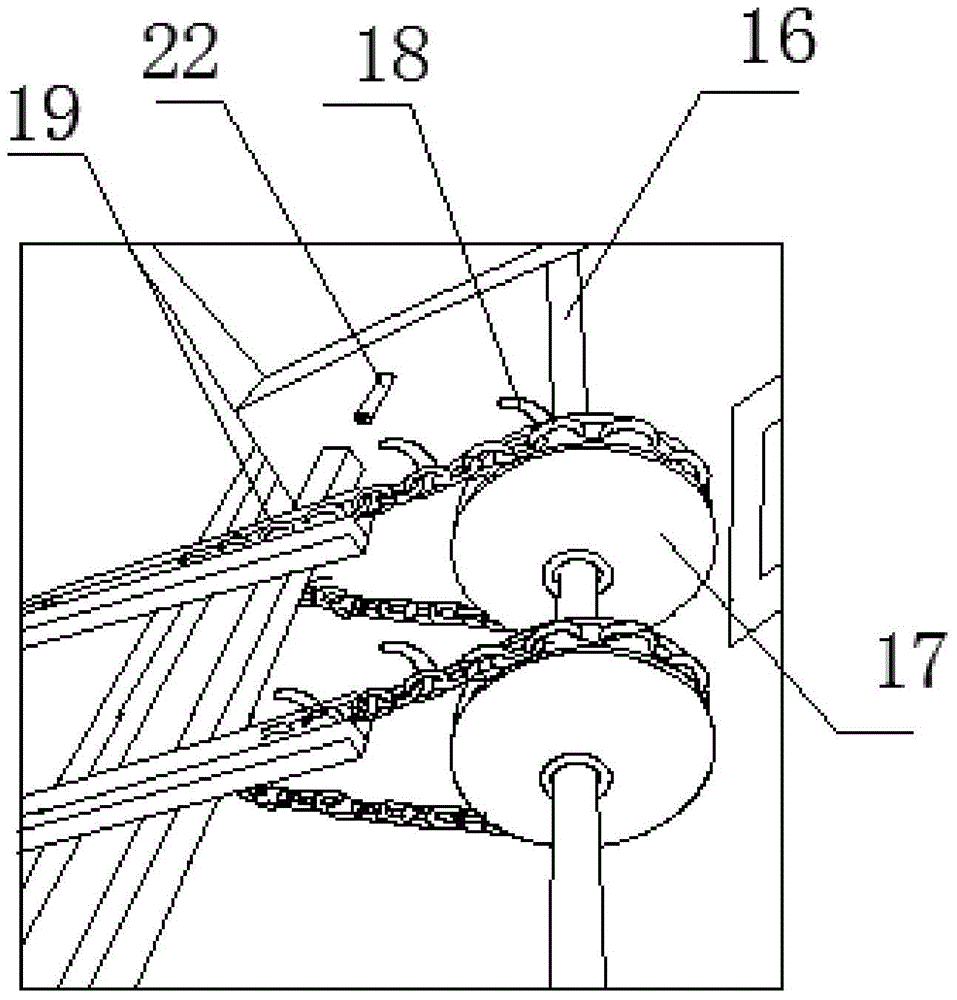

[0026] The flushing unit 2 includes a first housing 5, on which a motor 6 is arranged, and a longitudinal beam 7 is arranged in the first housing 5, the longitudinal beam 7 has a groove, and the two ends of the longitudinal beam 7 A drive wheel 8 and a driven wheel (not shown) are respectively provided with a chain 9 mounted on the drive wheel 8 and the driven wheel, a part of the chain 9 is located in the groove, and the chain 9 is also provided with a hook 10, and the motor 6 The driving wheel 8 is driven to rotate, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com