Side flanging mechanism of stamping die

A technology of stamping die and side flanging is applied in the field of auxiliary devices of stamping die, which can solve the problems of increasing workload, unfavorable work efficiency, increasing maintenance cost, etc., and achieves the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

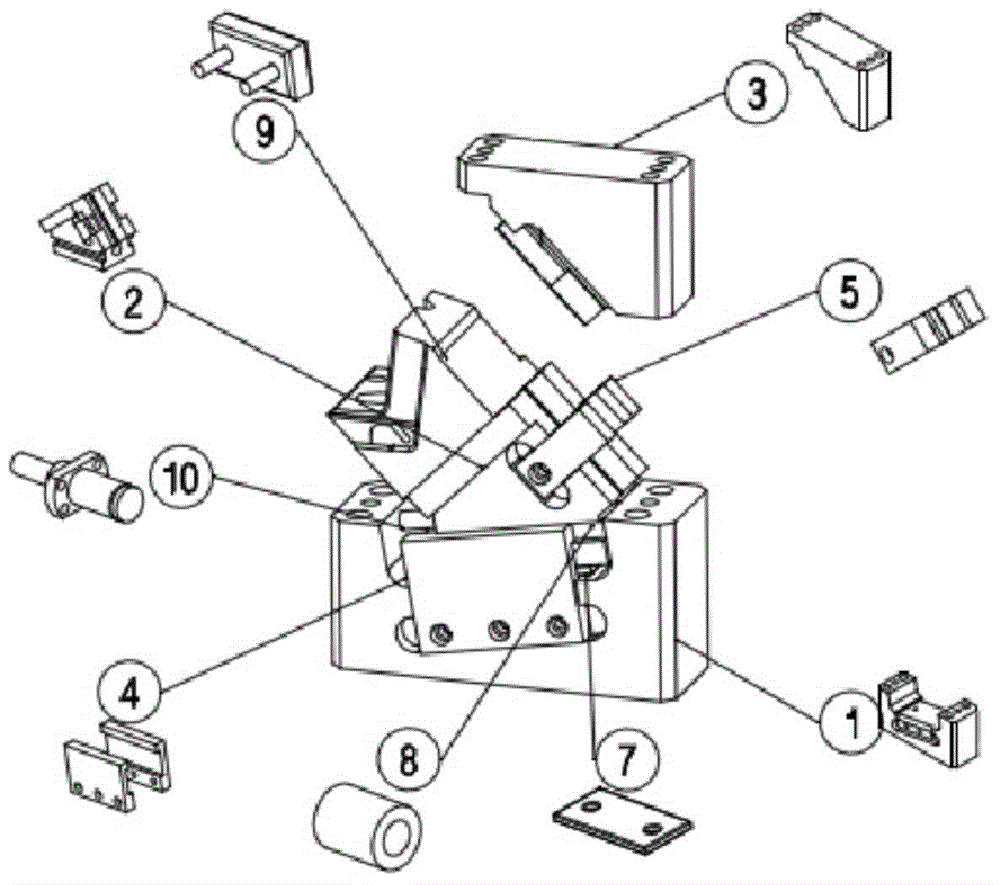

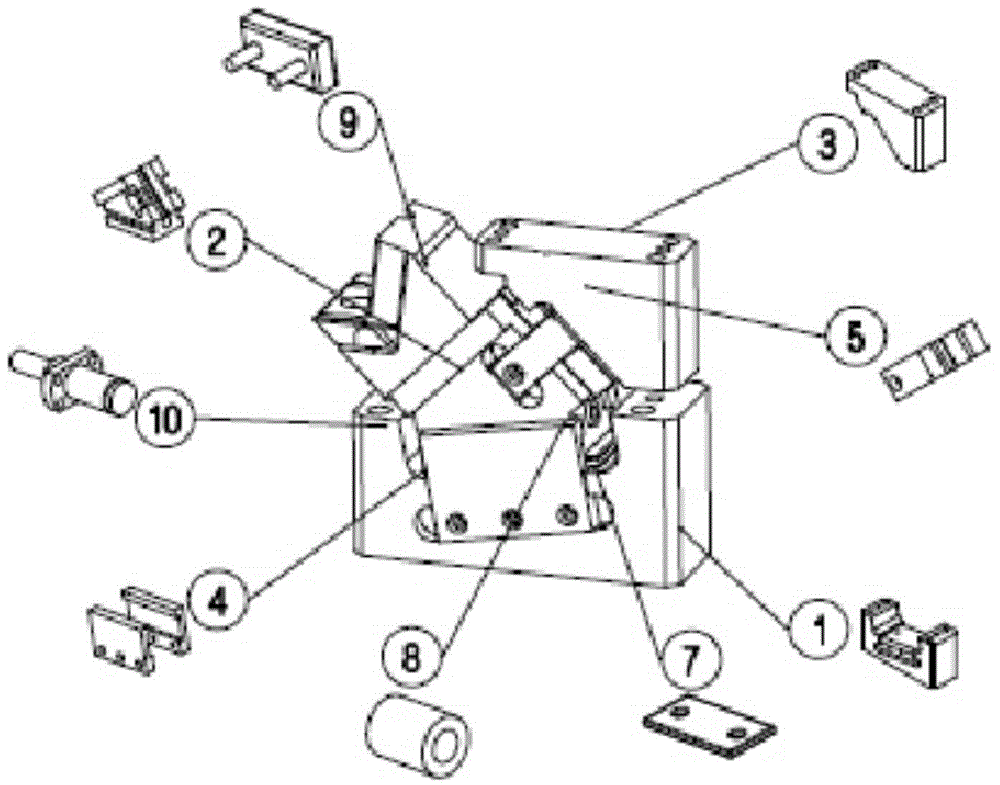

[0020] Such as figure 1 with 2 The stamping die side flanging mechanism shown includes a U-shaped slider fixing seat 1, a slider 2, an oblique pressure block 3, and a nitrogen cylinder 10;

[0021] The U-shaped sliding block fixing seat 1 is arranged on the lower mold of the mold, and is fixedly connected by bolts. The shape of the U-like slider fixing seat 1 is that the left side of the horizontal part is relatively low on the side close to the flange of the mold, and the other side is relatively high.

[0022] A slide rail 7 is provided on the upper end surface of the horizontal part of the similar U-shaped slider fixing seat 1; in this embodiment, considering the factors of processing cost and working hours, the sliding rail 7 and the U-like slider fixing seat 1 are used to process the final The way of final assembly can also be integrally processed and formed. The mode of installing after separating two pieces of processing, after long-term use, after the slide rail 7 w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap