Electric cable cutter

A cable and guillotine technology, applied in the field of cable guillotine, can solve the problems of not easy fixing of cables, waste of human resources, time-consuming and laborious cutting, etc., and achieve the effects of reducing labor force, improving work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

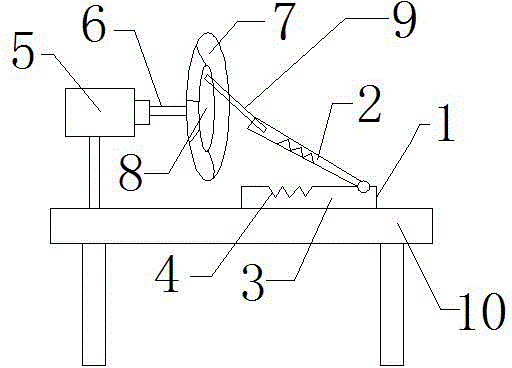

[0013] Such as figure 1 A cable guillotine shown includes a guillotine body 1 and a motor 5 composed of a knife seat 3 and a blade 2; the guillotine body 1 and the motor 5 are both arranged on a workbench 10; Transmission wheel 7; said transmission wheel 7 is provided with eccentric wheel 8; said eccentric wheel 8 is connected with blade 2 through transmission rod 9; said knife seat 3 is provided with " V " type cable through hole 4, has guaranteed The cable will not slide on the knife seat 3 during cutting, and the deformation of the cable cut can be reduced, thereby improving the quality.

[0014] Wherein, one or more "V"-shaped cable through holes 4 are provided; the blade 2 is provided with a "V"-shaped blade corresponding to the "V"-shaped cable through-hole 4 .

[0015] The cable guillotine of the present invention has reasonable design, simple structure and convenient use; the present invention drives the blade to work through the rotation of the eccentric wheel, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com