Blade type milling cutter

A blade type, milling cutter technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of milling blade damage, easy heating of milling blades, and inability to ensure cooling of milling blades, and achieve a longer service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

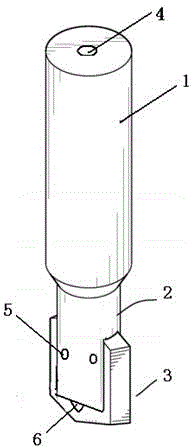

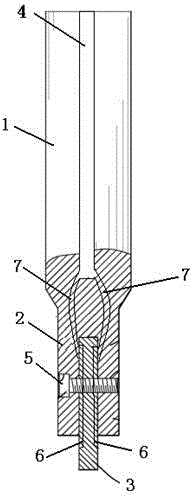

[0015] Such as figure 1 and 2 As shown, a blade type milling cutter includes a clamping part 1, a blade holder 2 and a milling blade 3, one end of the blade holder 2 is connected to one end of the clamping part 1, and the other end of the blade holder 2 is provided with a clamping groove, The clamping groove runs through the end face of the insert holder 2, the milling insert 3 is embedded in the clamping groove, and is fastened by a fastener 5, the fastener 5 is a bolt, and the bolt head of the bolt penetrates the milling insert 3 and is fastened to the insert holder 2 .

[0016] The above-mentioned clamping part 1 is a cylinder, and the clamping part 1 is provided with a first flow channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com