Indexing fixture

A fixture and indexing technology, used in clamping, clamping devices, manufacturing tools, etc., can solve the problems of insufficient positioning accuracy, unnecessary clearance errors, affecting machining accuracy, etc., to reduce vibration, improve machining accuracy, and improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

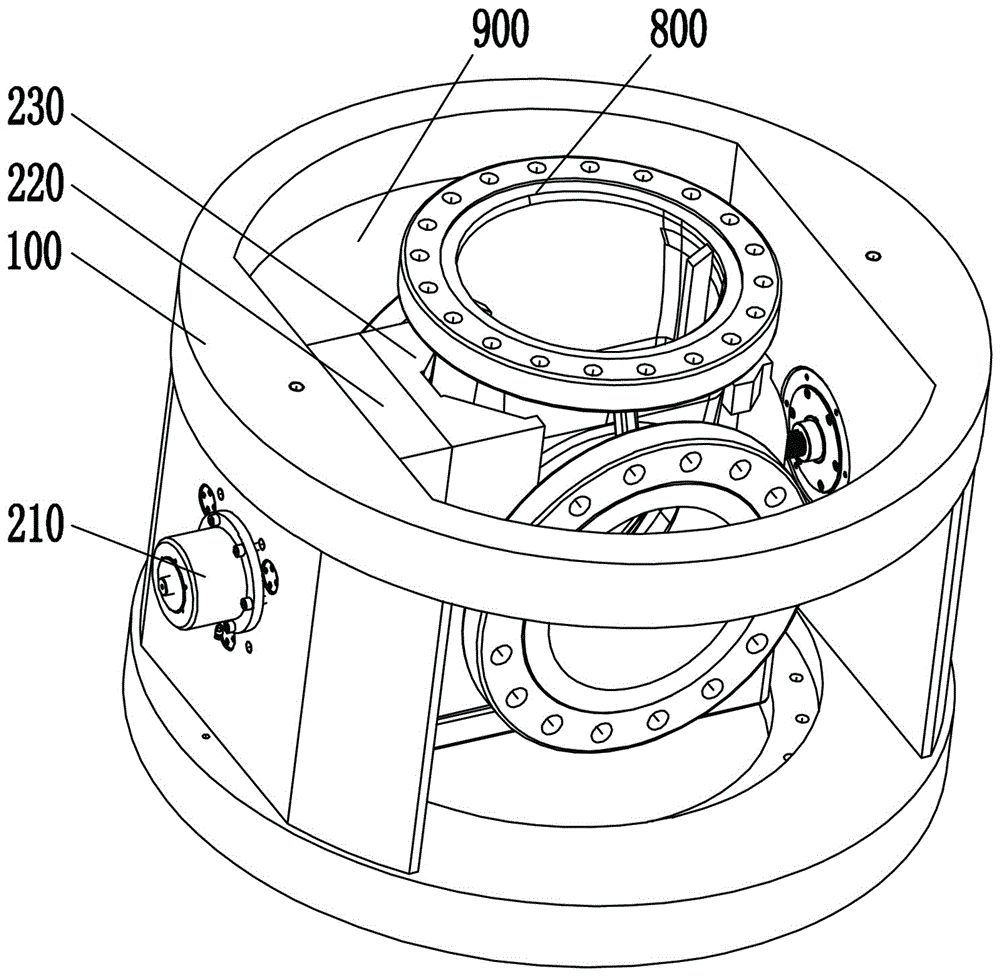

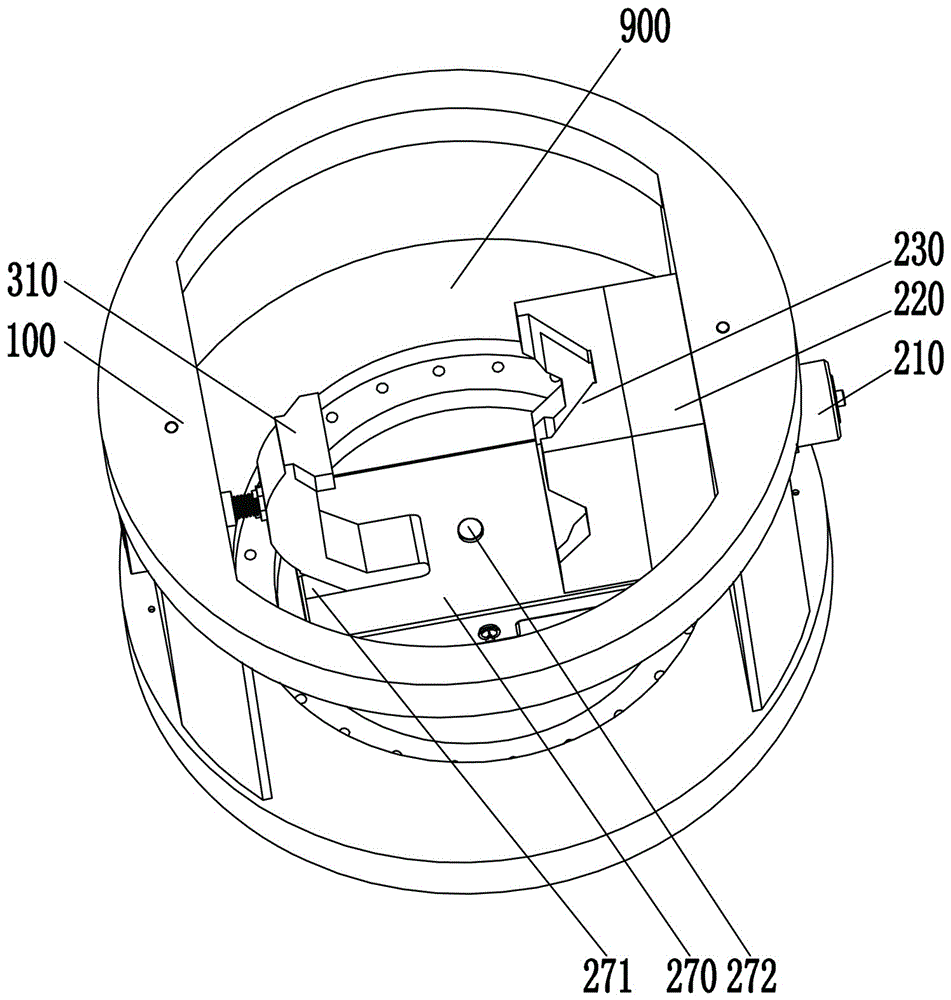

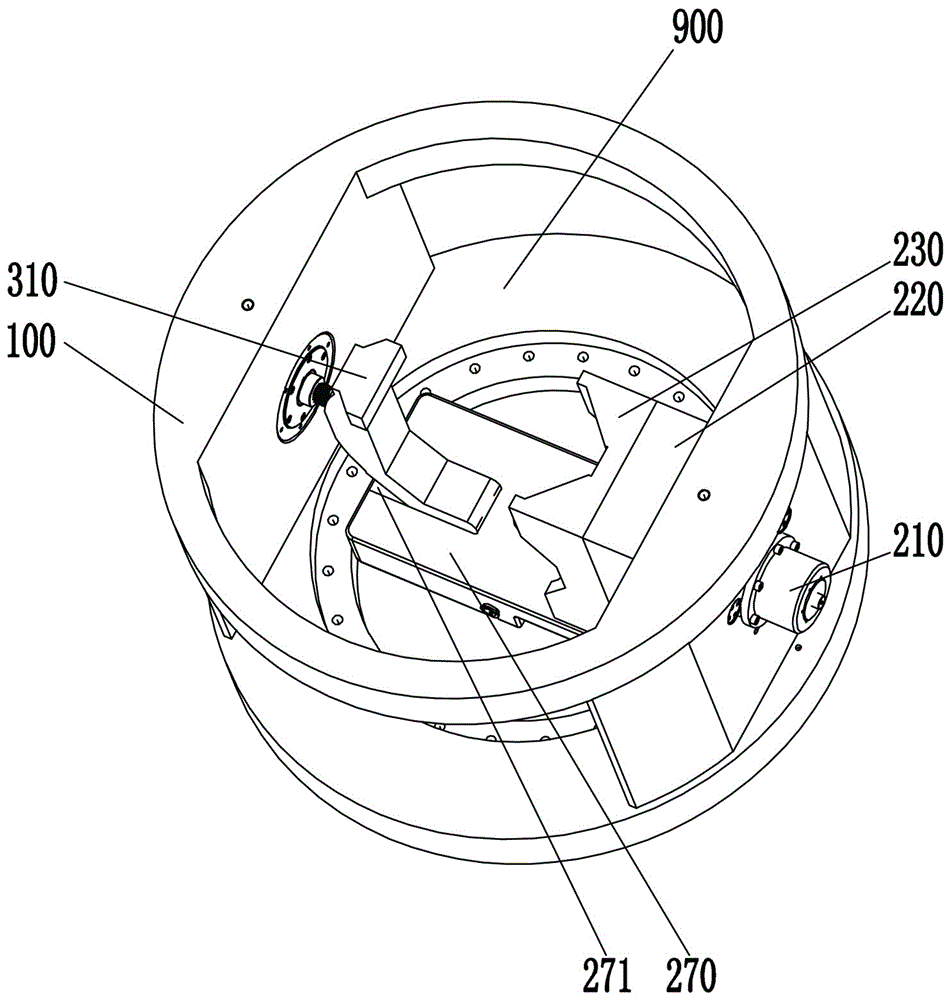

[0016] according to Figure 1 to Figure 4 , Figure 6 to Figure 8 As shown, the indexing fixture embodiment of the present invention includes a clamp body 100, the clamp body 100 has a housing space 900, the clamp body 100 is provided with a supporting device 200 and a pressing device 300, and the pressing device 300 includes a pressing plate 310, a pressing hydraulic pressure Cylinder 320, piston rod 330, connecting rod 340, compression hydraulic cylinder 320 and clamp body 100 are fixedly assembled, piston rod 330 is axially movable relative to compression hydraulic cylinder 320, and piston rod 330 is driven by compression hydraulic cylinder 320 to move axially , the connecting rod 340 and the piston rod 330 are axially fixedly assembled, the connecting rod 340 and the piston rod 330 are axially adjusted relative to each other, the connecting rod 340 and the pressure plate 310 are axially fixedly assembled, the pressure plate 310 is rotatably assembled relative to the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com