Micro motor

A micro-motor and micro-technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing friction loss of rotor components, left-right deviation, and reducing motor efficiency, etc., and achieve low assembly requirements and ensure axial concentricity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

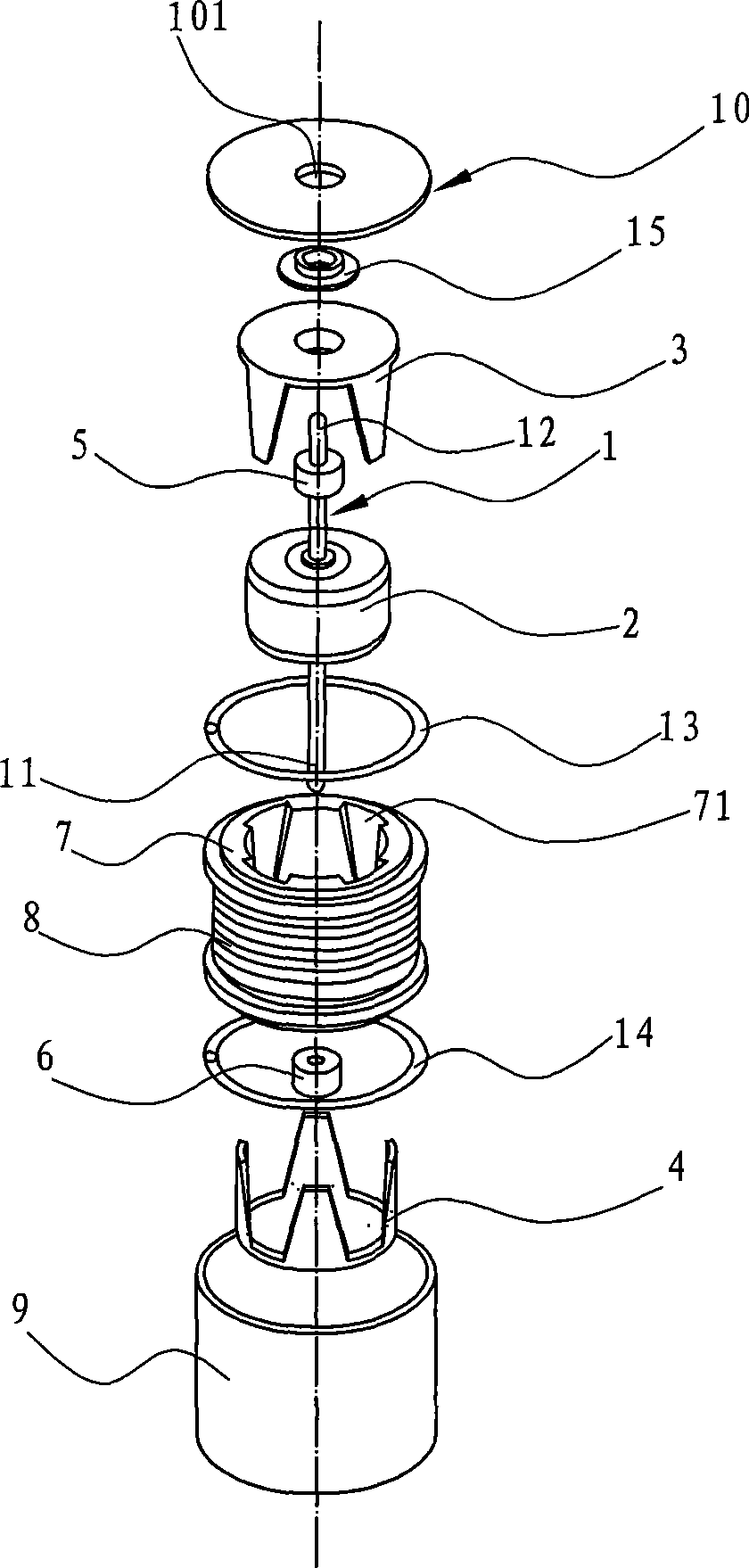

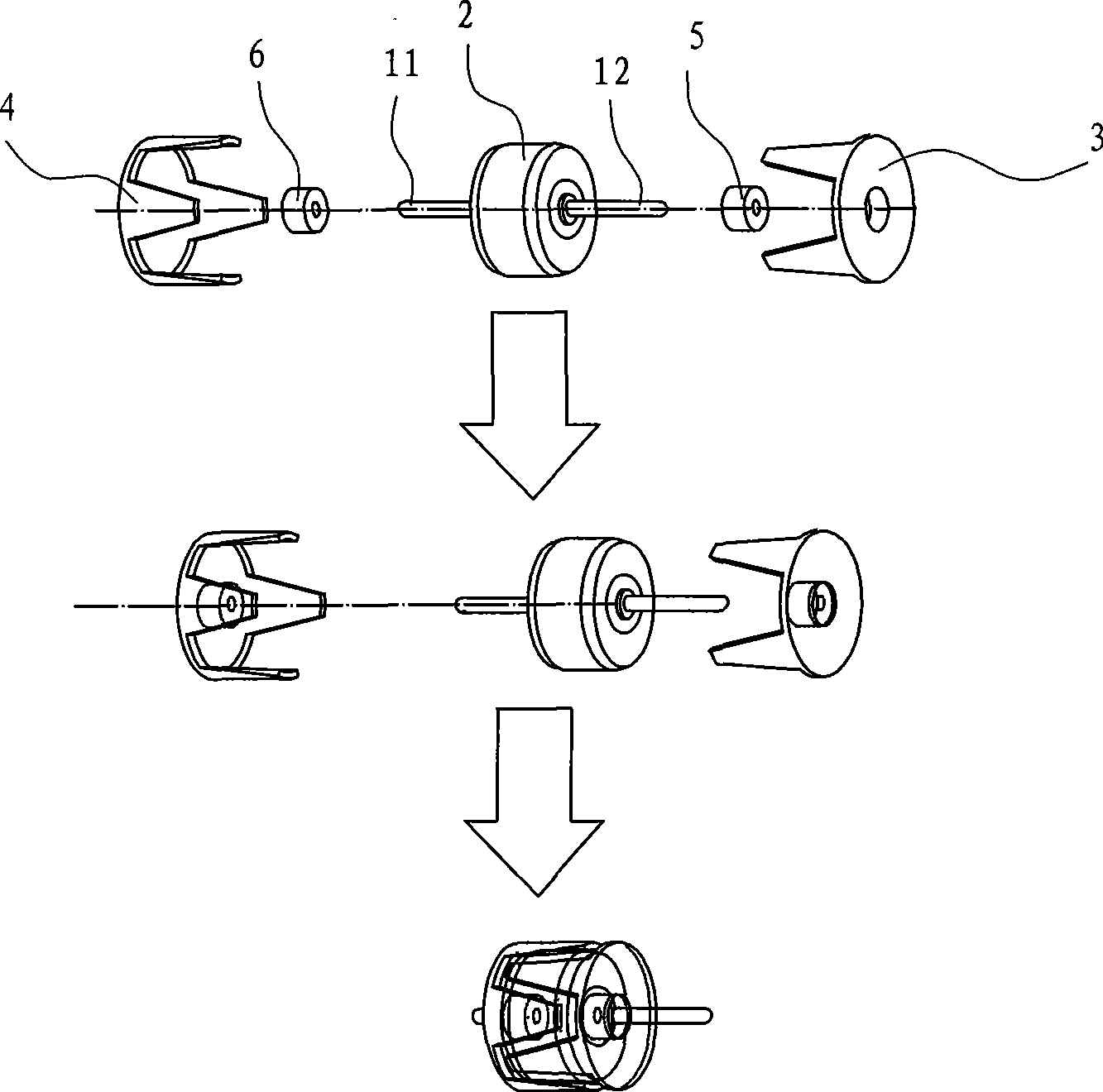

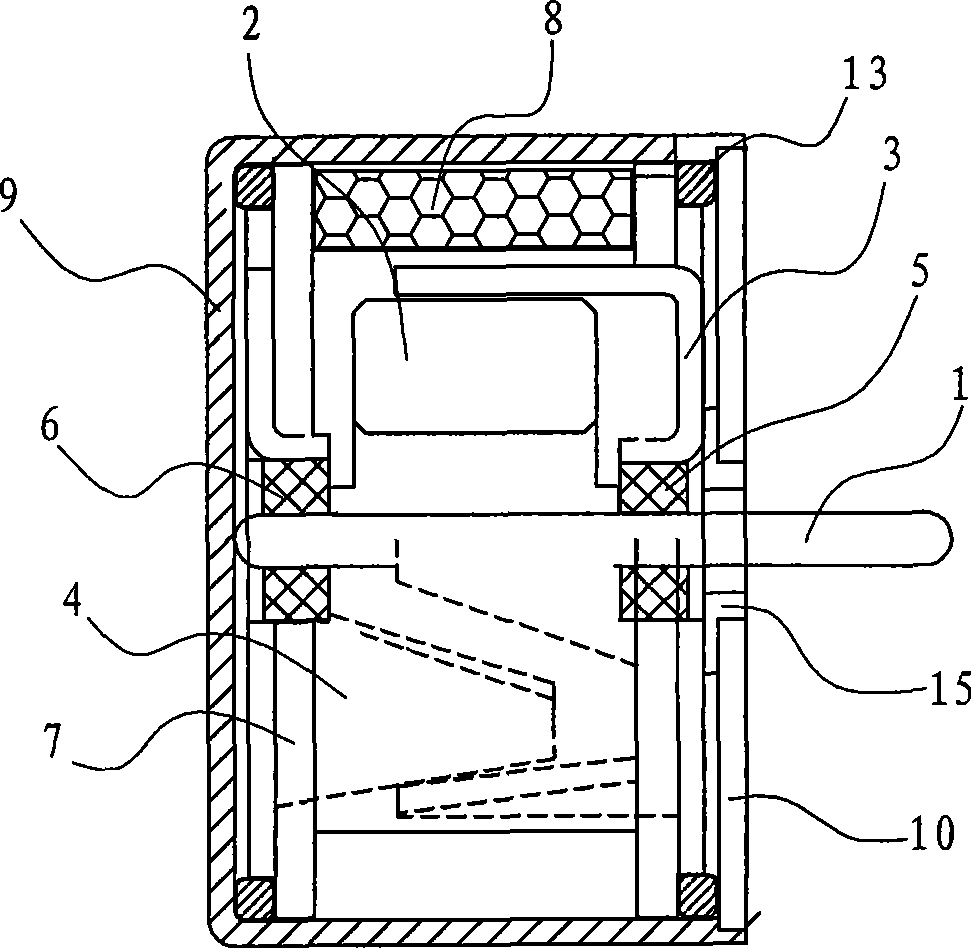

[0020] Such as Figure 1~3 The micro motor shown includes a rotor assembly formed by a stainless steel shaft 1 and a ferrite permanent magnet rotor 2 through a mold positioning injection molding process. , a stator assembly composed of a hollow tubular stator frame 7 and a stator coil 8 wound on the outer surface of the stator frame, wherein the front claw pole 3 and the rear claw pole 4 are stainless steel toothed claw poles, which are also formed by stamping at one time, and the front claw poles and the center hole of the rear claw pole are turned inward to form a bushing hole, the front bushing 5 is directly embedded in the center hole 31 of the front claw pole 3, and the rear bushing 6 is directly embedded in the center hole 41 of the rear claw pole 4, Then the rear end 11 of the rotating shaft 1 formed once with the permanent magnet roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com