Novel floating chuck

A floating chuck, a new type of technology, applied in the mechanical field, can solve the problems affecting the working efficiency of the grinding machine, the general clamping effect, the simple structure, etc., to improve the machining accuracy and production efficiency, the clamping effect is good, and the clamping force is evenly distributed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0052] The invention protects a new type of floating chuck, which can be used to clamp shafts to be processed by the grinding machine, so that the grinding machine can use the grinding tool to grind the surface of the workpiece to be processed. Of course, the chuck of the present invention can also be used to clamp similar shafts Components.

[0053] Most of the existing collets have simple structural design, poor clamping effect and easy loosening of the workpiece during processing, which affects the working efficiency of the actual machine tool. Therefore, it is necessary to design a new type of reasonable floating chuck.

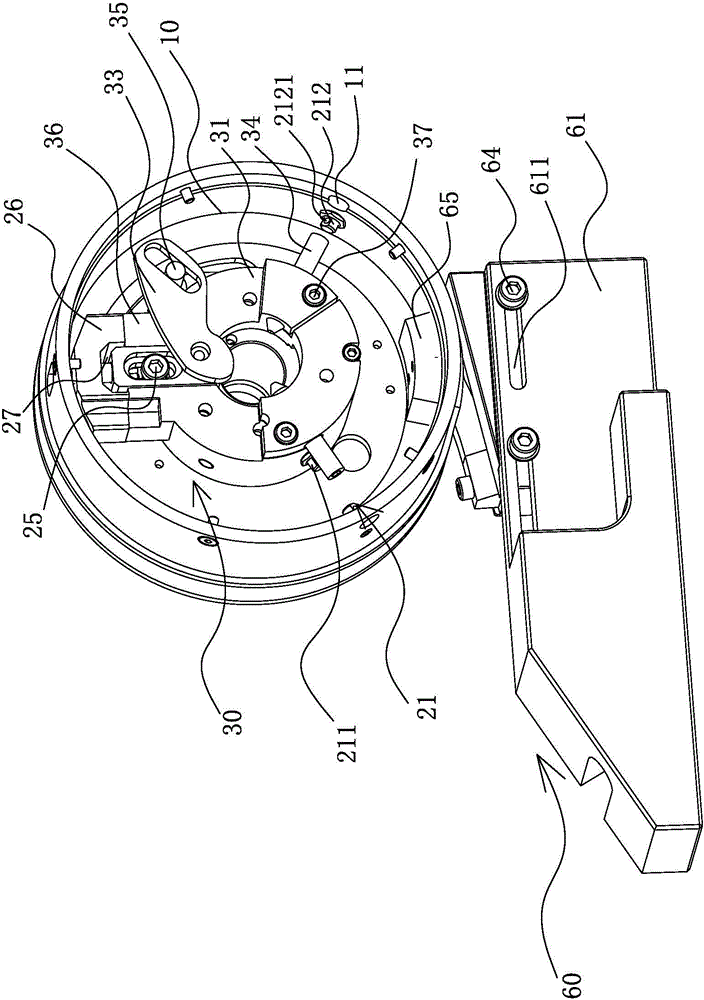

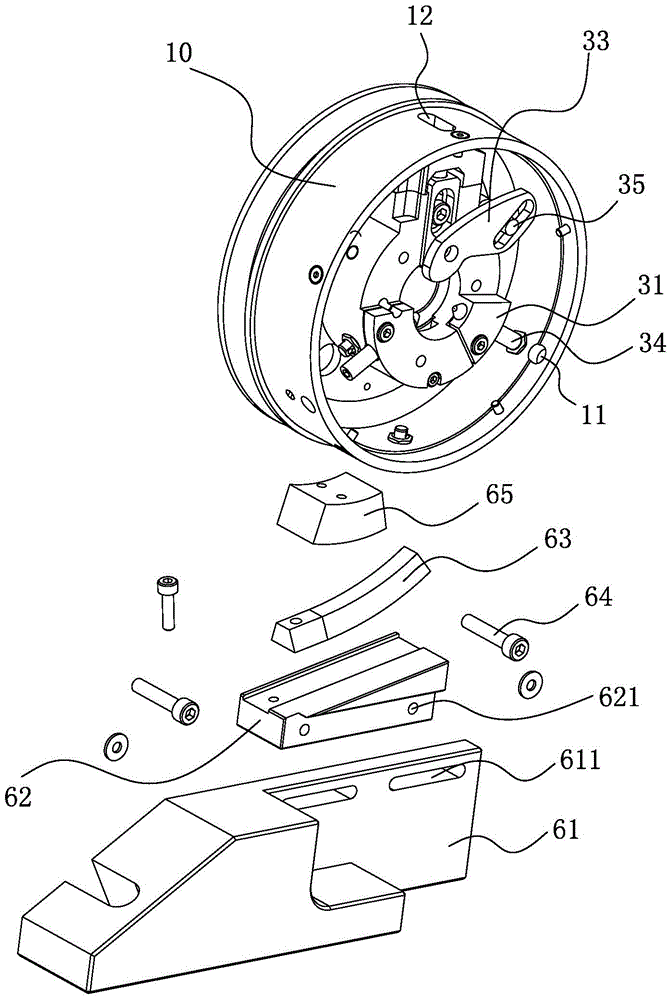

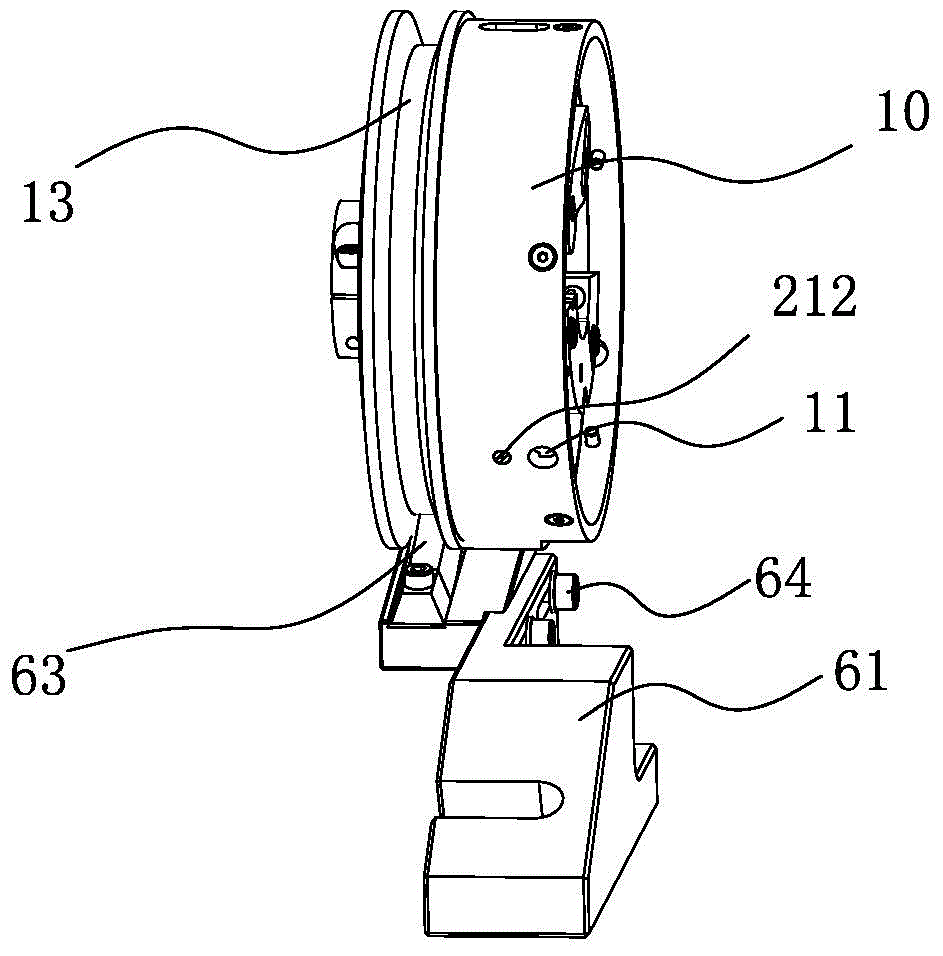

[0054] Such as Figure 1 to Figure 20 As shown, the new type of floating chuck includes a housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com