Mobile Fixture Holder

A fixture frame and mold technology, which is applied in the direction of manufacturing tools, tool storage devices, workshop equipment, etc., can solve the problems that molds are not easy to be sorted and placed, and achieve the effects of saving costs, reducing the weight of the top, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

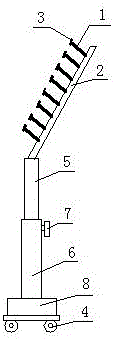

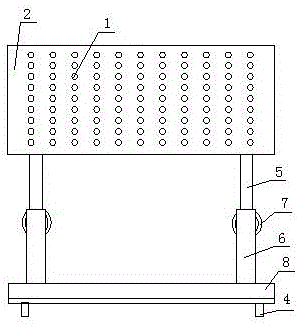

[0018] Such as figure 1 and figure 2 As shown, this embodiment provides a mobile fixture frame, including several hangers 1 for placing moulds, discharge panels 2 for fixing hangers 1 and bases for supporting discharge panels 2, and the hangers 1 are uniform Arranged and fixed on the discharge panel 2, the hanging rod 1 and the discharge panel 2 form an angle of 60-90°, preferably 75°, the discharge panel 2 is arranged on the base, and the discharge panel 2 There is an included angle of 150-170°, preferably 165°, with the base. The end of the hanging rod 1 is provided with a number of labels 3 for indicating the mold specifications, and the base is provided with a number of wheels for moving the base. 4. The base adopts an adjustable base, and the base includes an upper support 5, a lower support 6 and a rotating hand wheel 7 for fixing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com