Concrete water tank splicing module forming machine

A forming machine and concrete technology, which is applied in the direction of ceramic forming machines, forming indenters, manufacturing tools, etc., can solve the problems of uneven distribution of concrete raw materials, large differences in the strength of water tanks, unstable product properties, etc., and achieve good forming effects, Effects of small variation in tank strength and stable product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

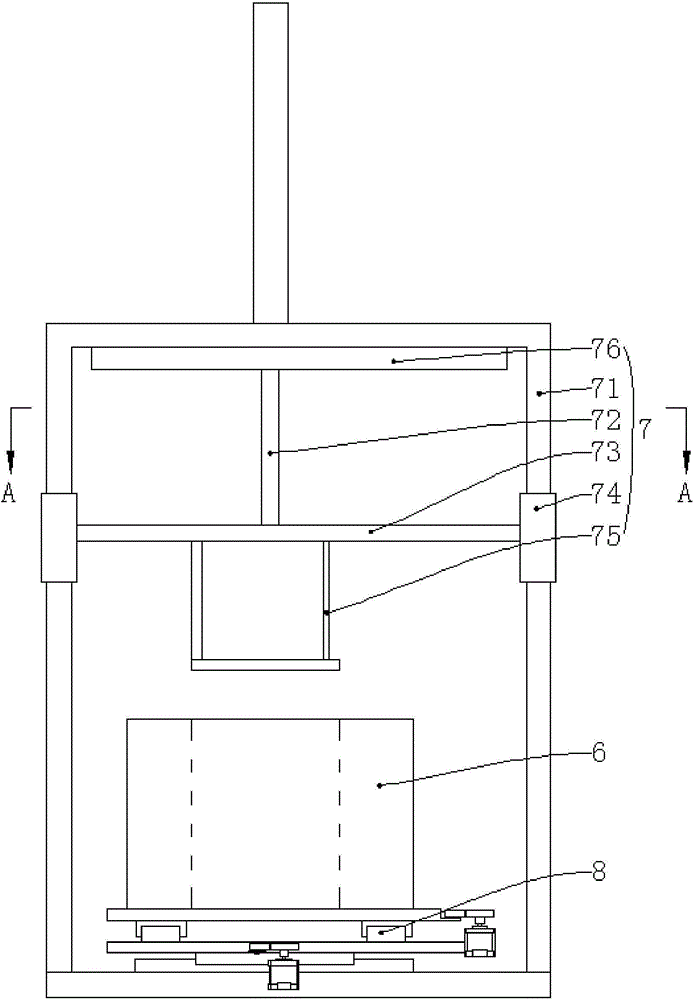

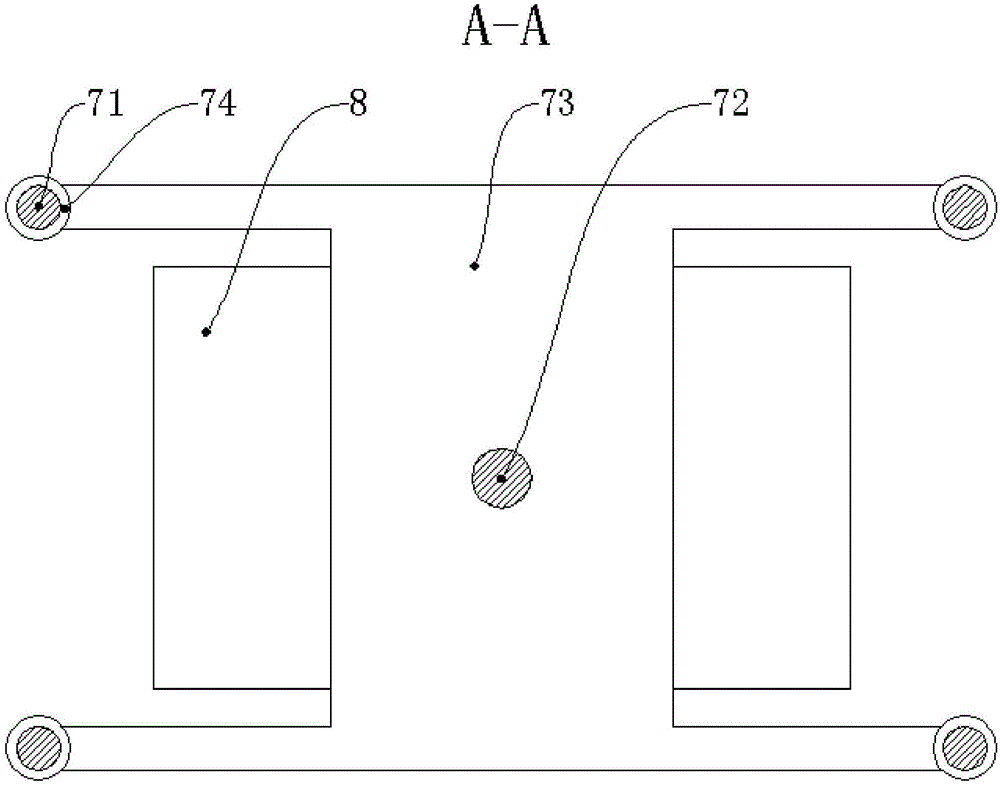

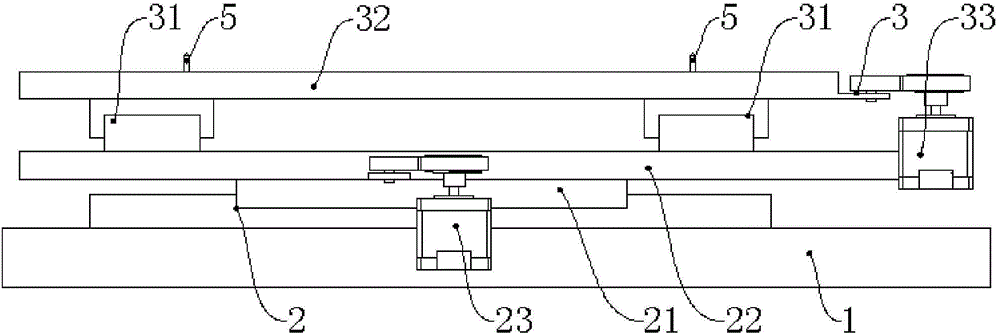

[0020] Such as Figure 1 to Figure 4 As shown, a concrete water tank splicing module forming machine includes a lower model body 6 and an upper model compression mechanism 7 arranged directly above the lower model body 6. The upper model compression mechanism 7 includes a door frame 71, and the door frame The crossbeam of 71 is fixedly provided with compression cylinder 72, is provided with guide frame 73 between the crossbeam of described door frame 71 and lower model body 6, is provided with guide sleeve 74 on the vertical support of described door frame 71, The outer wall of the guide sleeve 74 is fixedly connected to the guide frame 73, and the lower end of the piston rod of the compression cylinder 72 is fixedly connected to the guide frame 73. An upper frame is provided between the guide frame 73 and the lower mold body 6. Model body 75, this upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com