Lifting handle mechanical arm

A manipulator and handle technology, applied in the field of plastic processing machinery, can solve problems such as low efficiency, potential safety hazards, industrial accidents, etc., and achieve the effect of improving production efficiency, ensuring safety, and accurate movements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

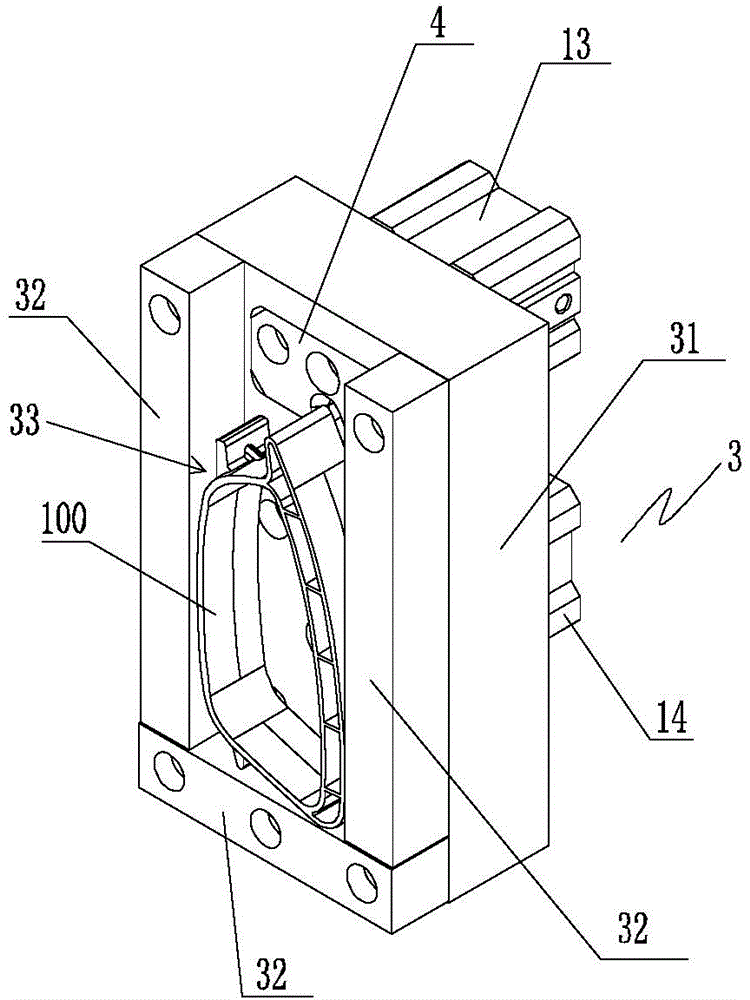

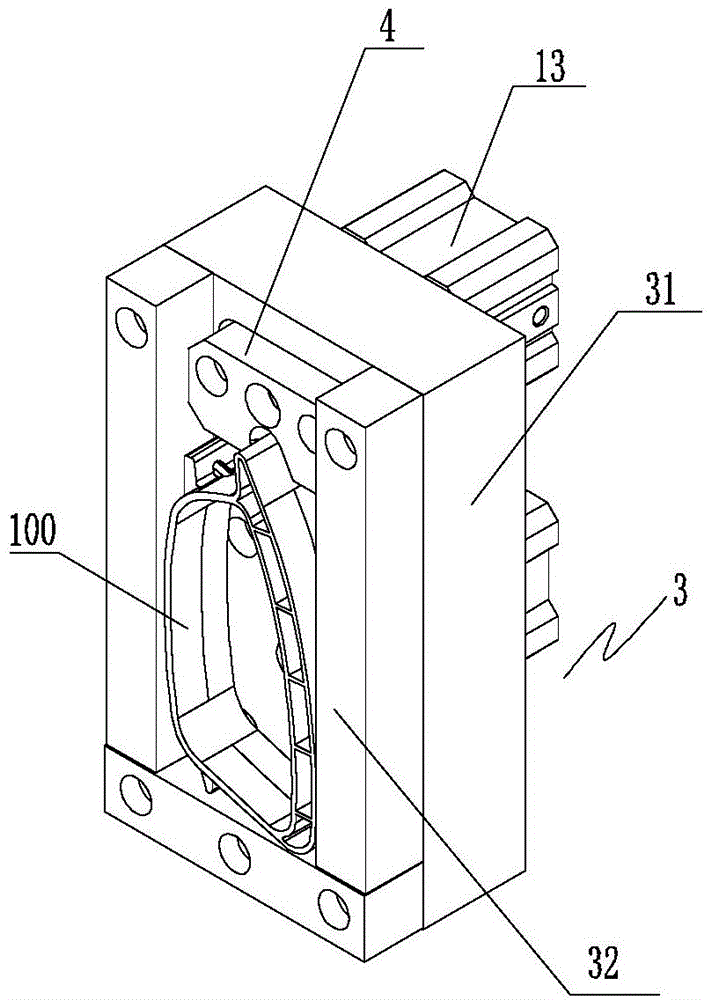

[0021] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the parts in the present invention that are the same as those of the prior art will be referred to the prior art.

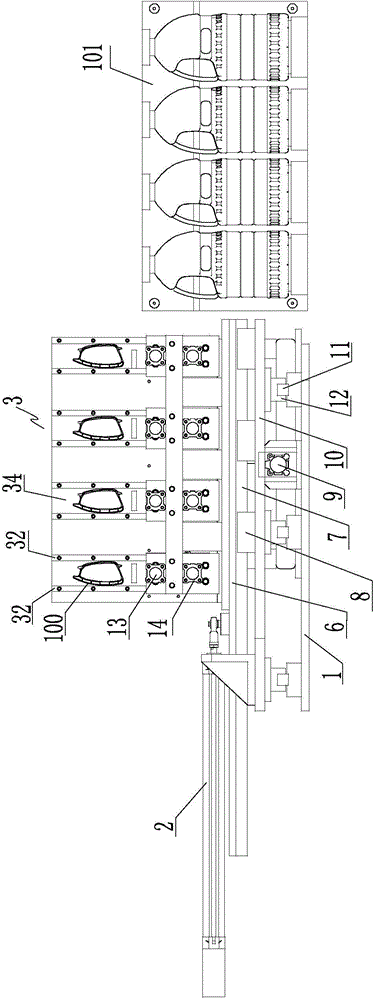

[0022] Such as Figure 1-5 As shown, the handle manipulator of the present invention includes a base 1 and a set of manipulators 3 that are arranged on the base 1 and can move back and forth under the action of the first power device 2. In this embodiment, a set of manipulators includes 4 Each manipulator 3 includes a main body 31, the two sides and the bottom of the main body 31 are respectively provided with stoppers 32 so as to form accommodating cavity 33 that can accommodate the handle, and the main body 31 is provided with a retractable device to push the handle The push block 5, specifically, the push block 5 expands and contracts under the action of the fourth power device 14, and when the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com