Automatic bagging device for independent plastic bag

A bagging device and plastic bag technology, applied in packaging and other directions, can solve problems such as staying and affecting the cost of packaging and labor of enterprises, and achieve the effect of precise operation and reduction of labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

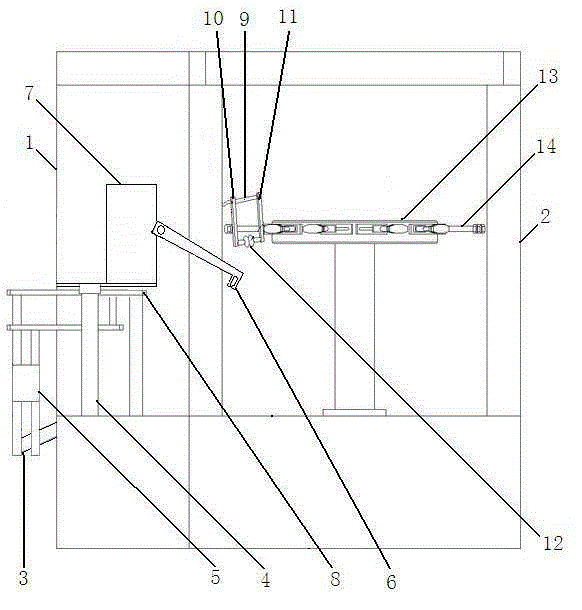

[0020] Embodiment 1: The controller calculates the running interval of each program according to the pre-input packaging bag parameters. First command the action of the bag-out cylinder, the bag-out suction cup 8 will suck out the plastic bags individually and leave the bag box 7 to avoid overlapping bags, and then command the action of the bag-grabbing cylinder and the bag-feeding pneumatic actuator 3, and the bag-grabbing hand 6 will move to the bag box 7 At the bottom, the gripper of the bag grabber 6 clamps the mouth of the packaging bag sucked out from the bag box 7, and then rises, and the plastic packaging bag is converted from horizontal to vertical and passed to the transmission unit and the bag opening unit.

Embodiment 2

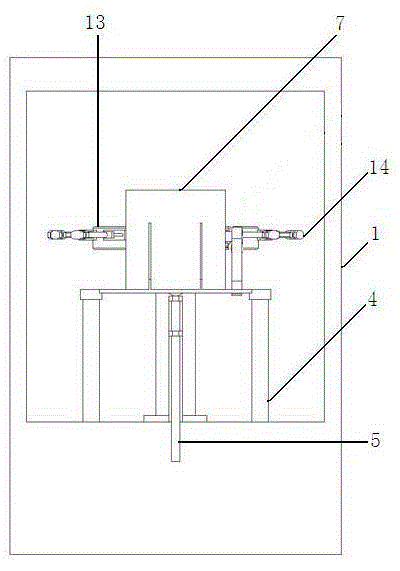

[0021] Embodiment 2: When the packaging bag is moved between the two clamping arms 14, the controller instructs the bag clamping cylinder to act, and the two jaws of the clamping arm 14 clamp the two sides of the packaging bag at the same time.

Embodiment 3

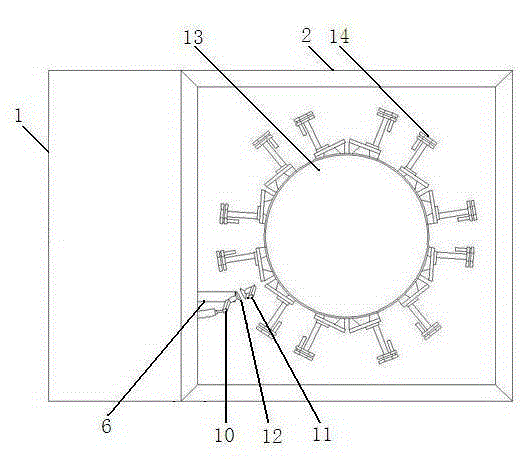

[0022] Example 3: After the two sides of the packaging bag are clamped by the jaws, the controller instructs the bag opening cylinder and the bag opening pneumatic actuator to act successively. After the left and right bag opening suction cups 12 suck the two sides of the packaging bag, the bag opening pneumatic actuator Pull the left bag opening arm 10 to move and open the bag opening, and what is synchronized with the bag opening pneumatic actuator is the opening cylinder, and the opening cylinder drives two clamping arms 14 to move towards the direction of approaching, and the opening of the bag is strutted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com