Batching device and batching method applied to stacker conveying mechanism

A conveying mechanism and stacking machine technology, applied in the field of stacking machines, can solve problems such as batching errors and unfavorable batching, and achieve the effects of reducing cardboard damage and downtime, reducing waste and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

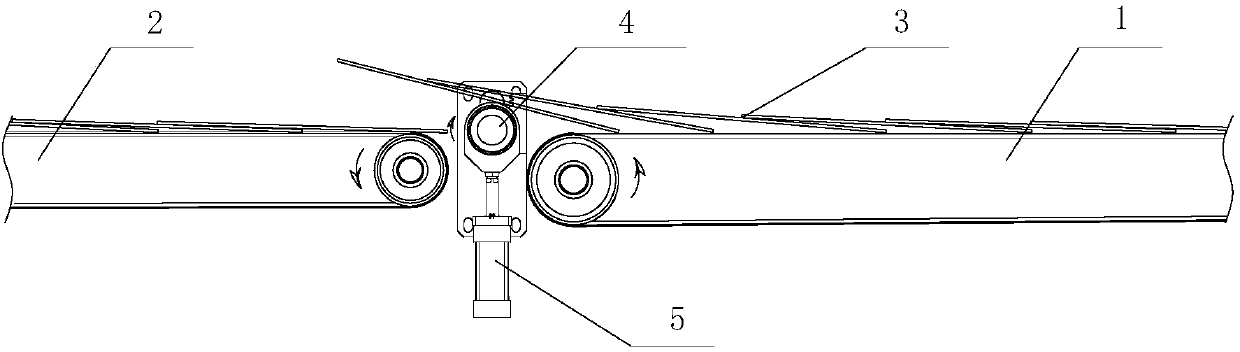

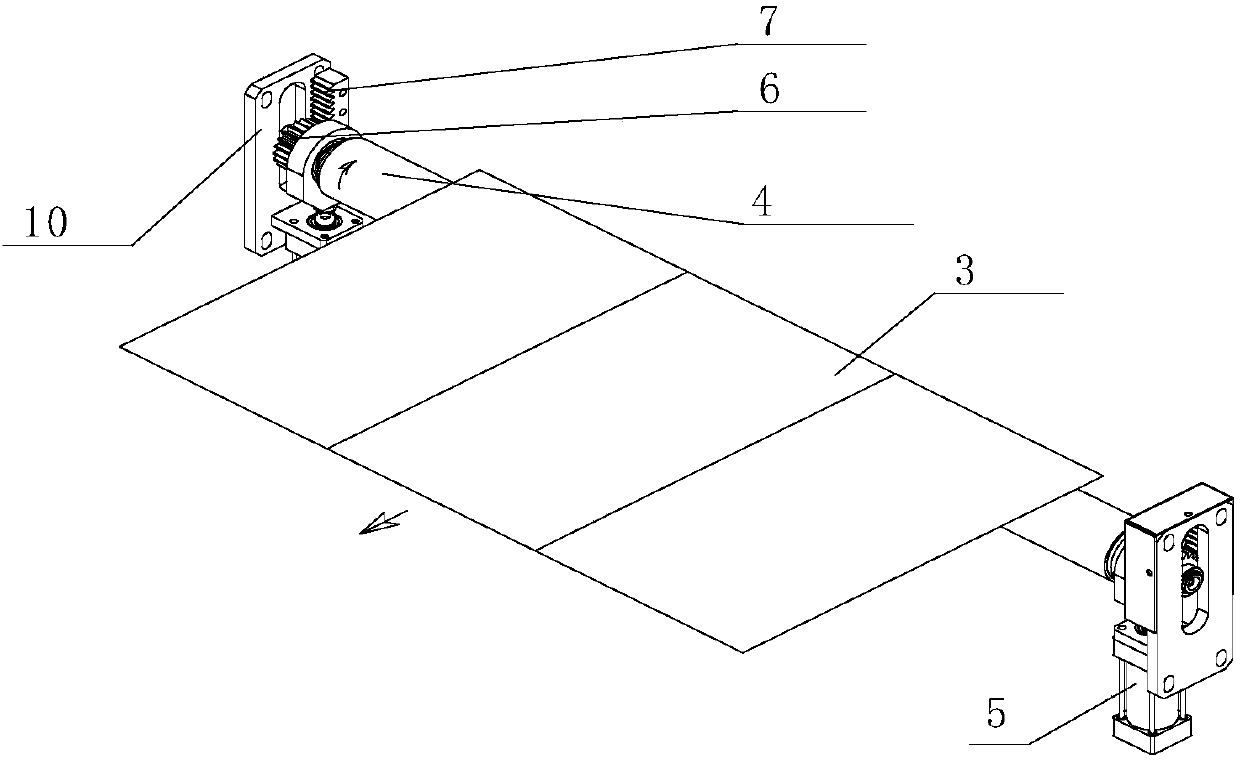

[0022] combine figure 1 , 2 Describe this embodiment, a batching device applied to the conveying mechanism of a stacker, the conveying mechanism includes a first conveying section 1 and a second conveying section 2, paper 3 is conveyed from the first conveying section 1 to the second conveying section 2, The batching device includes a rotary jack 4 installed between the first conveying section 1 and the second conveying section 2, a cylinder 5 for driving the rotary jack 4 to move up and down, arm plates 10 located at both ends of the rotary jack 4, and The gear 6 at the two ends of the rotary push rod 4 and the rack 7 arranged vertically on the arm plate 10, the gear 6 meshes with the rack 7, and the rack 7 is arranged on the side close to the first conveying section 1. The cross section of the rotating mandrel 4 is circular, and the surface of the rotating mandrel 4 is provided with a friction layer, which is made of a layer of material with strong friction. A vertical ch...

Embodiment 2

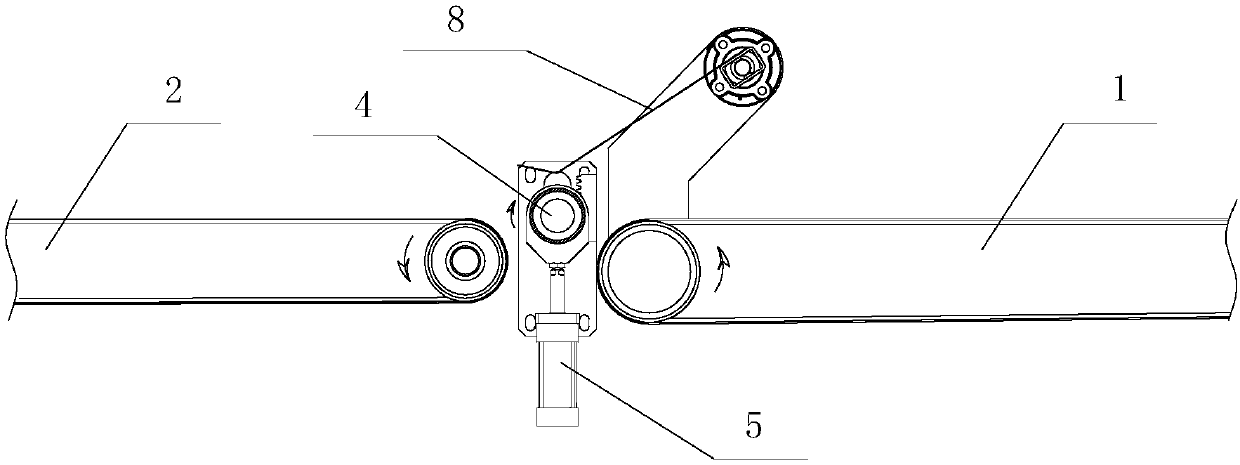

[0026] combine image 3 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that the batching device also includes a press brush 8, and the press brush 8 is arranged on the top of the first conveying section 1 near the side of the rotary ejector pin 4, and cooperates with the press brush 8 , the pulling force of the rotating mandrel 4 will be greatly strengthened, which is more conducive to batching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com