Process and special material for manufacturing plastic part with low cost

A low-cost technology for plastic parts, applied in the manufacturing industry, can solve problems such as increased development costs, high production costs, and extended development cycles, achieving high reliability, reduced development costs, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

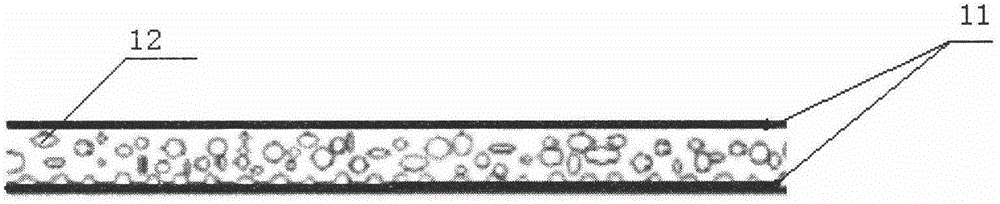

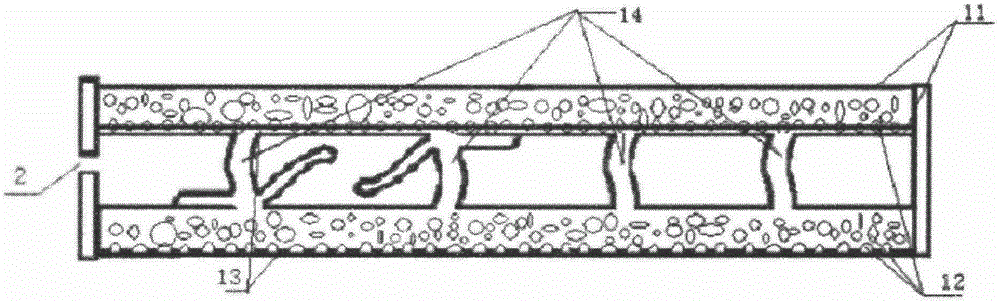

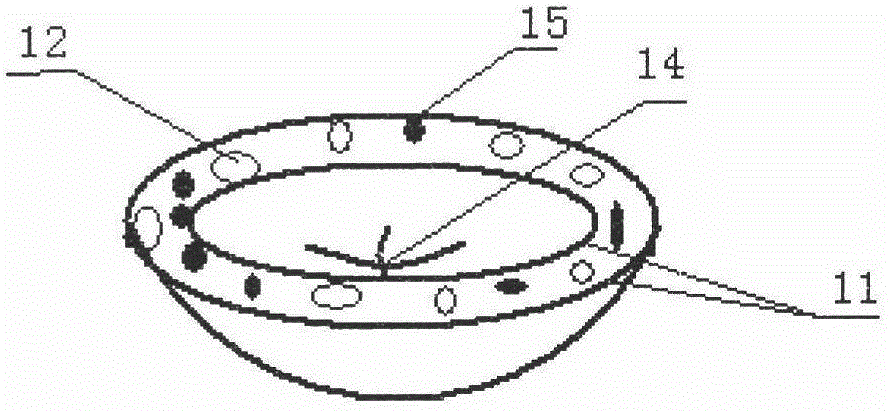

[0067] refer to figure 1 , figure 2 , image 3 or Figure 4 The special material for making plastic parts at low cost includes a substrate for producing product forms, the substrate includes at least two film layers 11, at least one film layer 11 of the two film layers 11 is a light-transmitting material. The uncured photocurable resin-based composite material is filled between the two film layers 11 . Resin-based composite materials are not solid before curing, so the matrix only needs to be able to form the shape of the product, and it does not require that it must be in the shape of the product or have a certain shape. Therefore, the degree of freedom in the shape of the matrix is high, and it can be made into different shapes accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com