A tire bezel wrapping device and method

A technology of cloth wrapping device and steel ring, which is applied in the direction of tires, other household appliances, household appliances, etc., can solve the problems of troublesome maintenance, low degree of automation, and complicated operation of winding machines, so as to reduce the number of manual refueling and increase the degree of automation , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings of the specification.

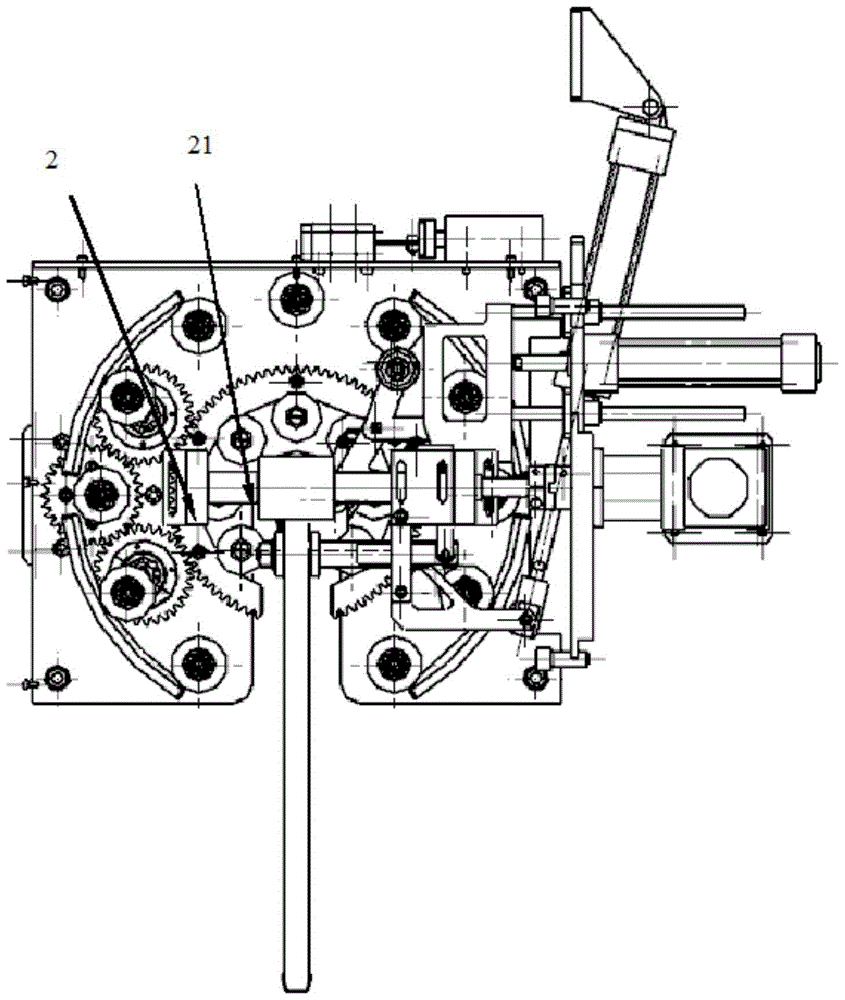

[0038] figure 1 As shown, a schematic diagram of the overall structure of the tire rim covering device provided by the present invention. Including the main drive module, the main winding module, the steel ring forward drive module, the tape cutting module, the tape clamping module, and the steel ring pressing module.

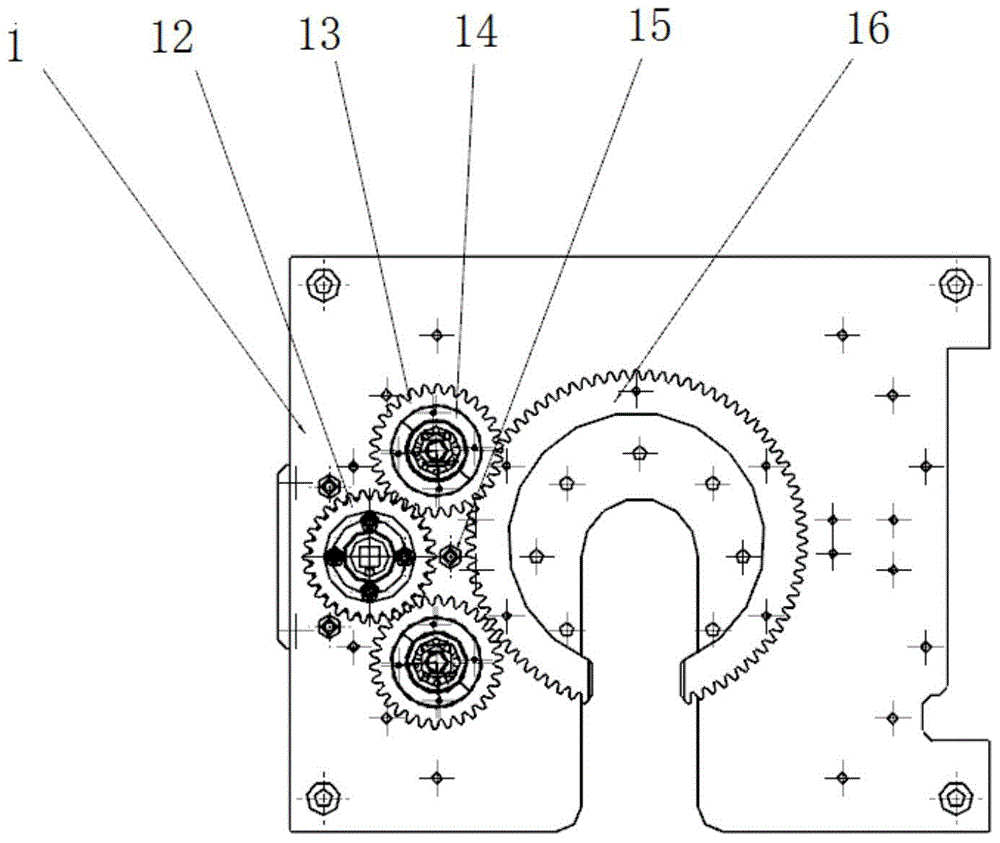

[0039] Figure 2 ~ Figure 4 As shown, the main drive module includes a drive motor 17, which is connected to the box body 1 by a hexagon socket screw 15 to provide a rotational torque for the gear. The two transmission gears 13 are also fixed on the box body by the bolt fixing member 14. The motor shaft is equipped with a gear 12, and the middle big wheel is also equipped with a big arc gear 16 through the hexagon socket screw. Through the meshing between the gears, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com