An improved structure at the end of luggage rack to overcome thermal expansion and contraction

A technology of thermal expansion and cold contraction, luggage rack, applied in the direction of vehicle parts, additional accessories, transportation and packaging, etc., can solve the problems of small internal space, unable to accommodate too many accompanying objects, unable to accommodate accompanying objects, etc., to achieve simple structure, Easy to install and fix, to ensure the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

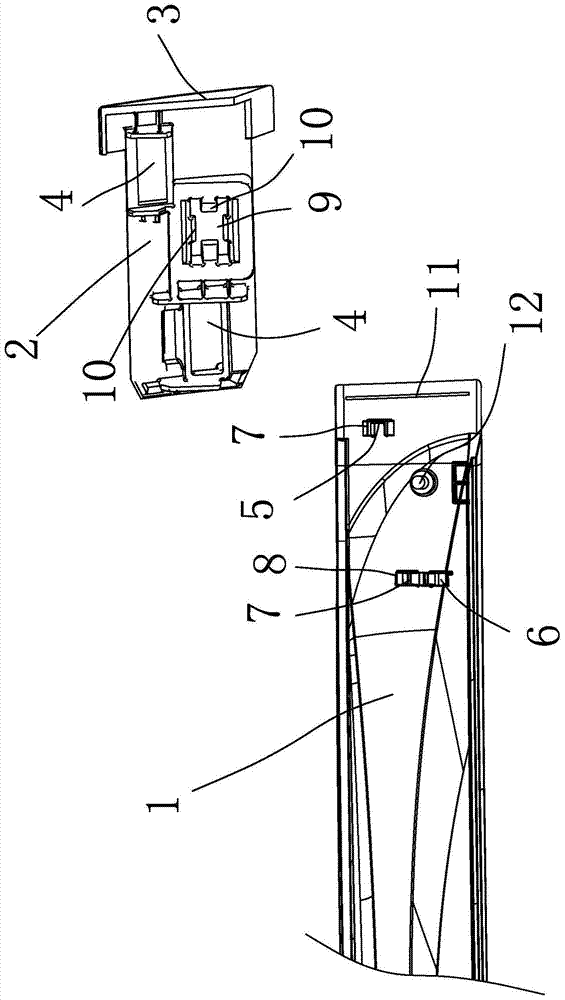

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

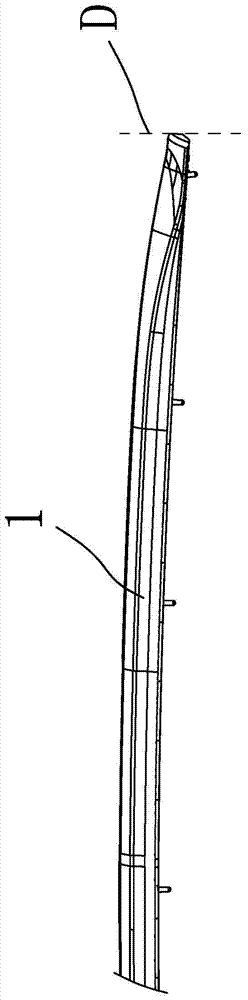

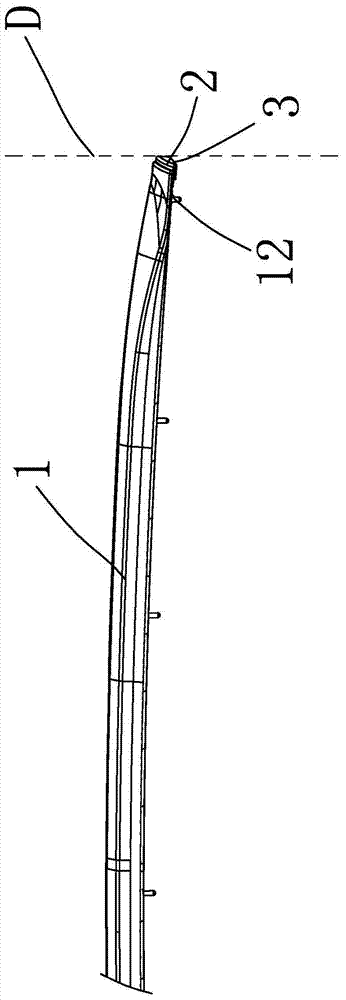

[0018] In the figure, luggage rack body 1; transition fit body 2; flanged end cover body 3; adjustment slot 4; first connecting buckle 5; second connecting buckle 6; Connect the locking groove 9; the top column body 10; the anti-slip convex rib 11; the roof fixing part 12; the right end surface D of the sheet metal.

[0019] Such as figure 2 as well as image 3 As shown, the improved structure for overcoming thermal expansion and contraction of the luggage rack includes a luggage rack body 1, a transition fit body 2 is arranged on the end of the luggage rack body 1, and a flanged end is provided on the end of the transition fit body 2 The cover body 3, the flanging end cover body 3 is flush with the right end surface D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com