Bicycle fast demounting structure

A bicycle and linkage rod technology, which is applied to bicycle racks, bicycle accessories, transportation and packaging, etc., can solve the problems of time-consuming, loose locking rod 10, poor endurance strength, etc., and achieve the effect of good safety function and stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

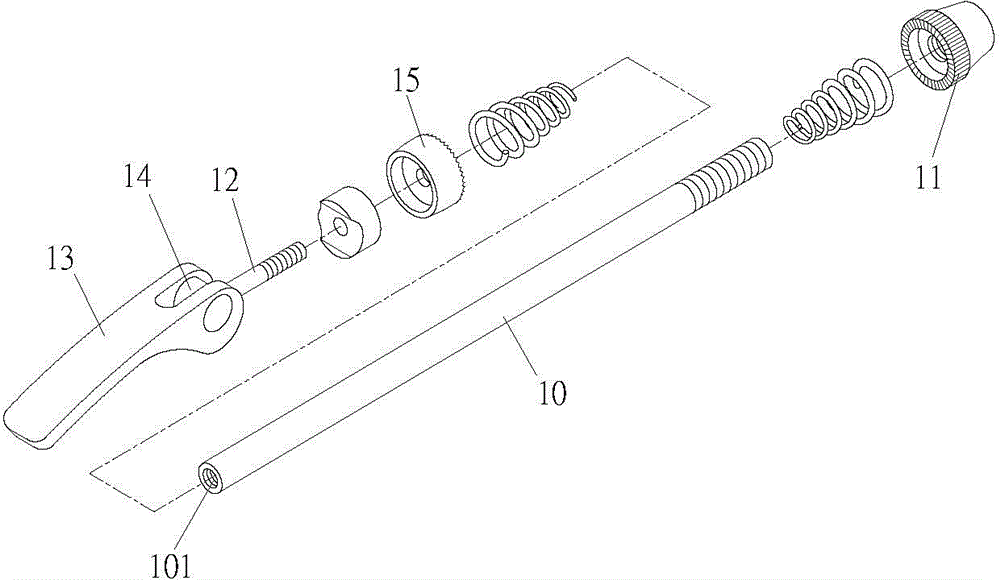

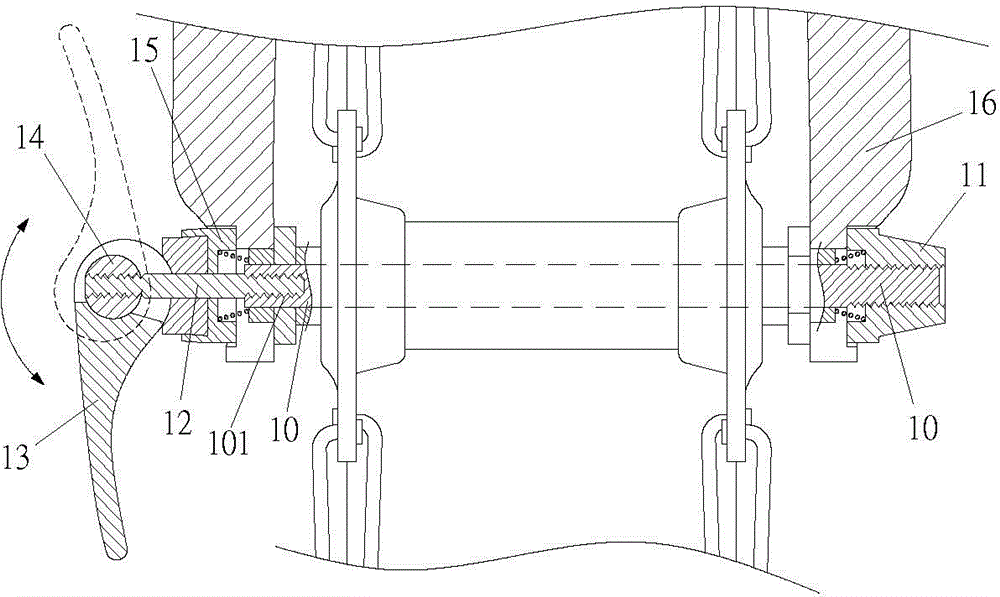

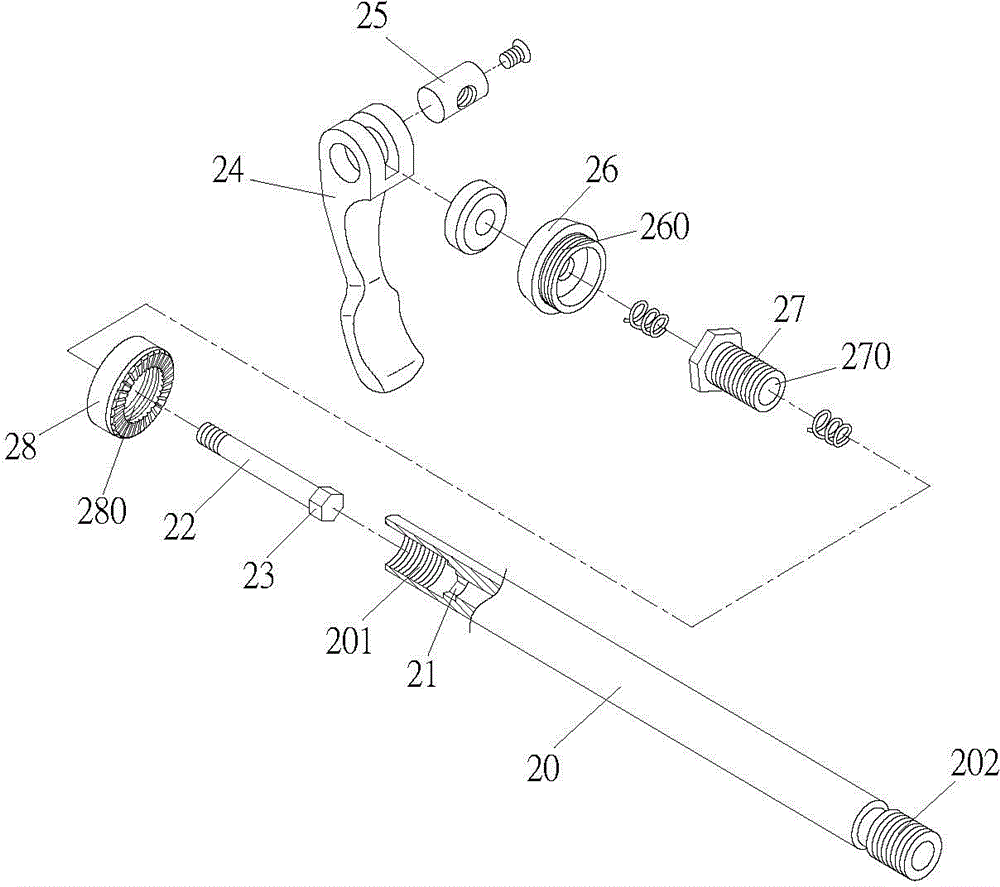

[0032] see image 3 , 4 , 5, 6, the bicycle quick release structure of the present invention comprises: lock force lever 20, linkage lever 22, positioning seat 28, link head 25, lock force handle 24; Linkage lever 22 is connected with link head 25, and is combined in In the locking handle 24, the linkage rod 22 is combined into the locking rod 20, and one end of the locking rod 20 has an external thread 202 and is locked to the frame 17; wherein, the other end of the locking rod 20 is provided with a screw hole 201, a polygonal groove 21 is provided in the screw hole 201; the linkage rod 22 is provided with a polygonal head 23 corresponding to the shape of the polygonal groove 21, and the locking handle 24 can make the linkage rod 22 advance to embed the polygonal head 23 into the locking force The polygonal groove 21 of the rod 20 forms the locking rod 20 that can be driven to rotate, and the linkage rod 22 can also retreat to make the polygonal head 23 break away from the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com