Large aspect ratio wing structure capable of lateral assembly and assembly method thereof

A technology with large aspect ratio and wing structure, applied in the aerospace field, can solve the problems of reducing disassembly and assembly, transportation efficiency, reducing the service life of the wing, disassembly and assembly, and transportation difficulties, so as to improve endurance and reduce instability. Destruction accident, the effect of light weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

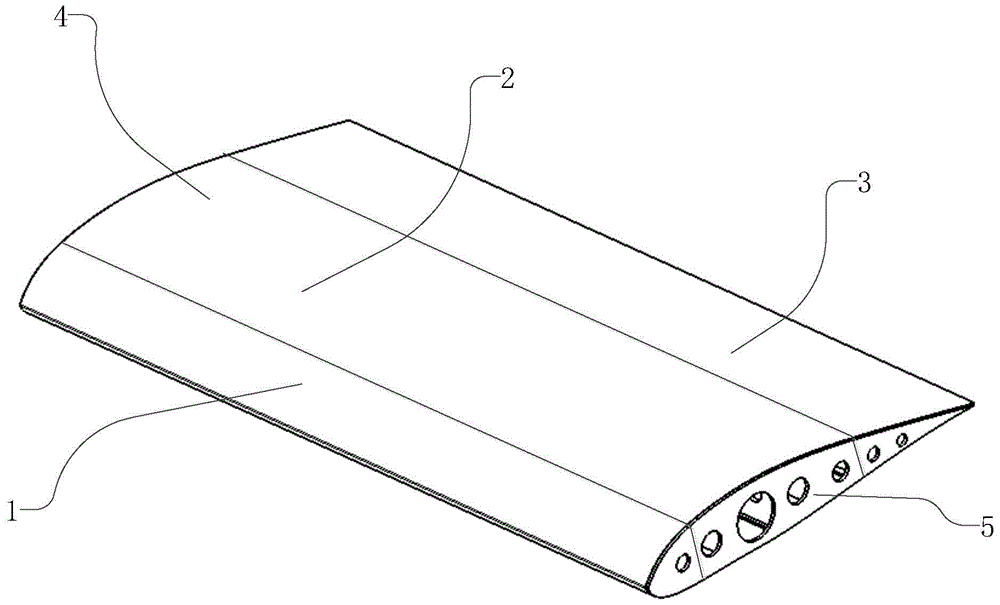

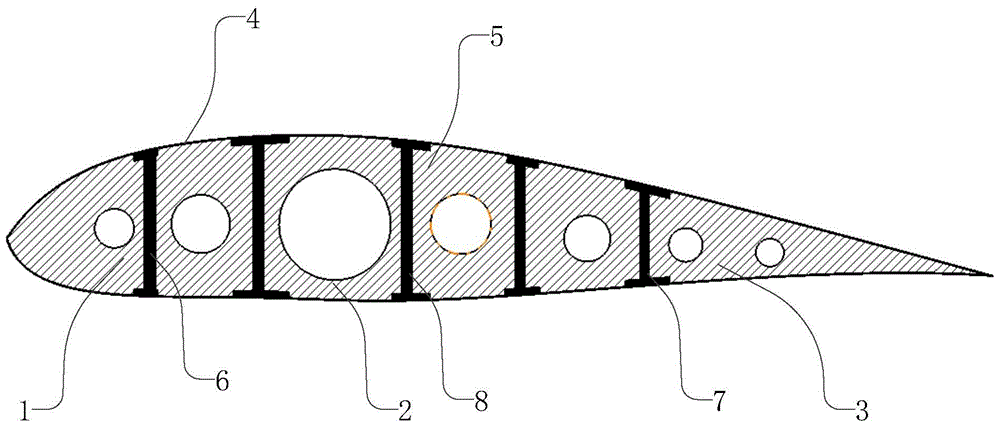

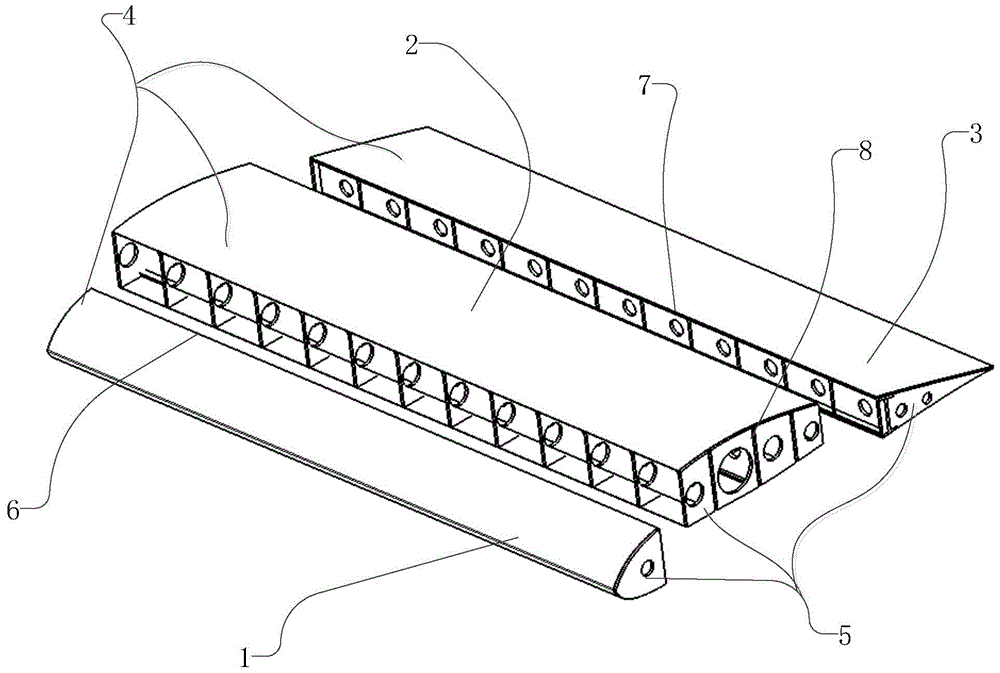

[0040] Such as Figure 1-7 As shown, a large aspect ratio wing structure that can be assembled laterally, it includes:

[0041] The leading edge assembly 1, the leading edge assembly 1 comprises a longitudinal front wall 6, a leading edge rib set and a leading edge skin 401, the leading edge rib set includes a plurality of leading edge ribs 501 arranged side by side longitudinally, the leading edge ribs 501 Both are fixedly connected to the longitudinal front wall 6, and the leading edge skin 401 is connected to the periphery of the leading edge rib group;

[0042] The spar assembly 2, the spar assembly 2 includes a longitudinal spar group, a reinforced rib group, an upper skin 4021 and a lower skin 4022, the longitudinal spar group includes a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com