A kind of automatic packing machine and cloth tape automatic packing method

A technology of automatic packaging machine and driving motor, which is used in packaging, packaging protection, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

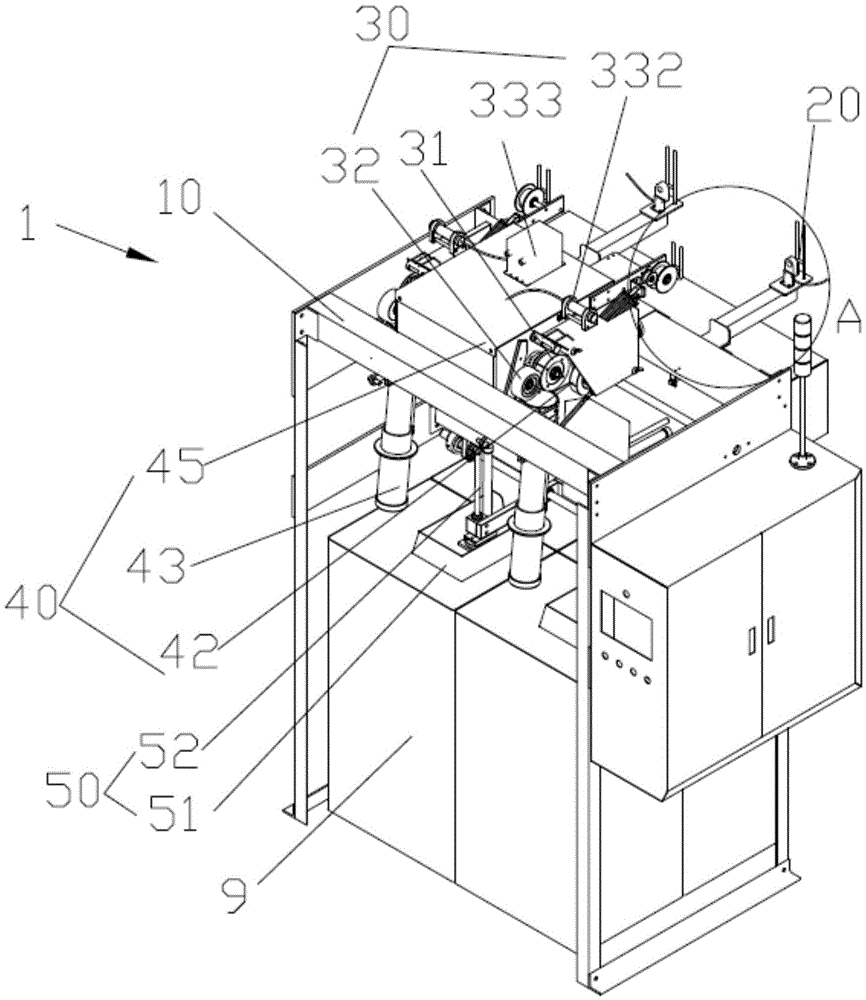

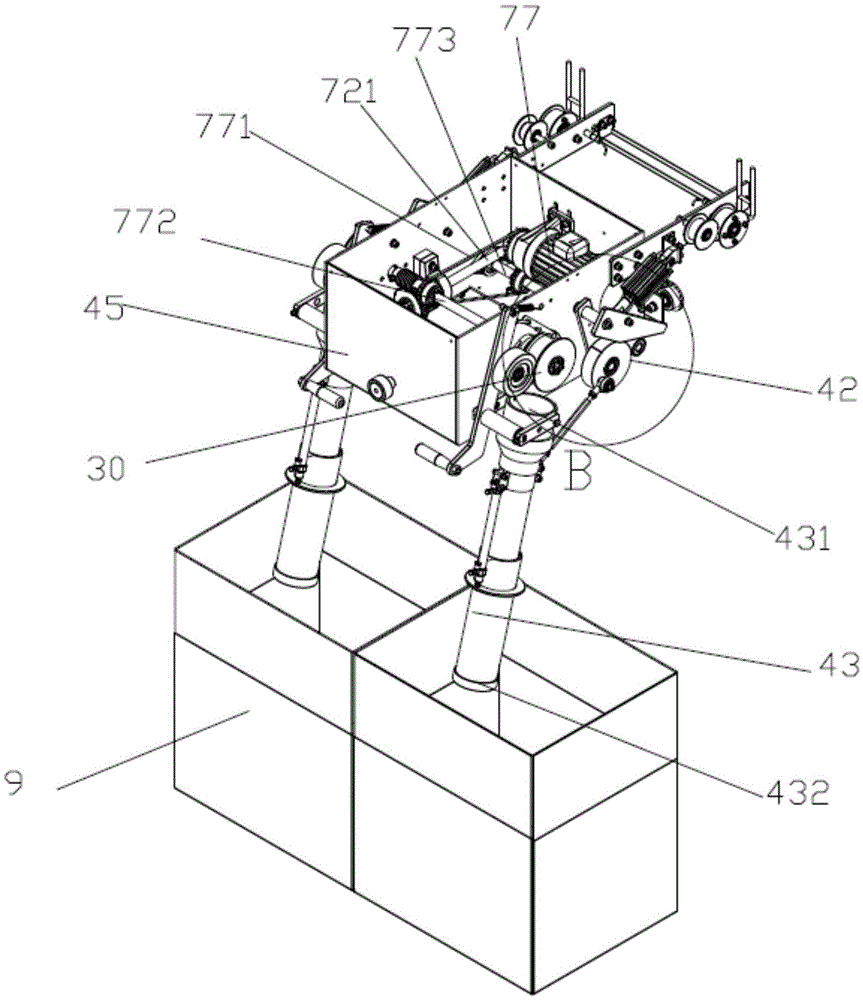

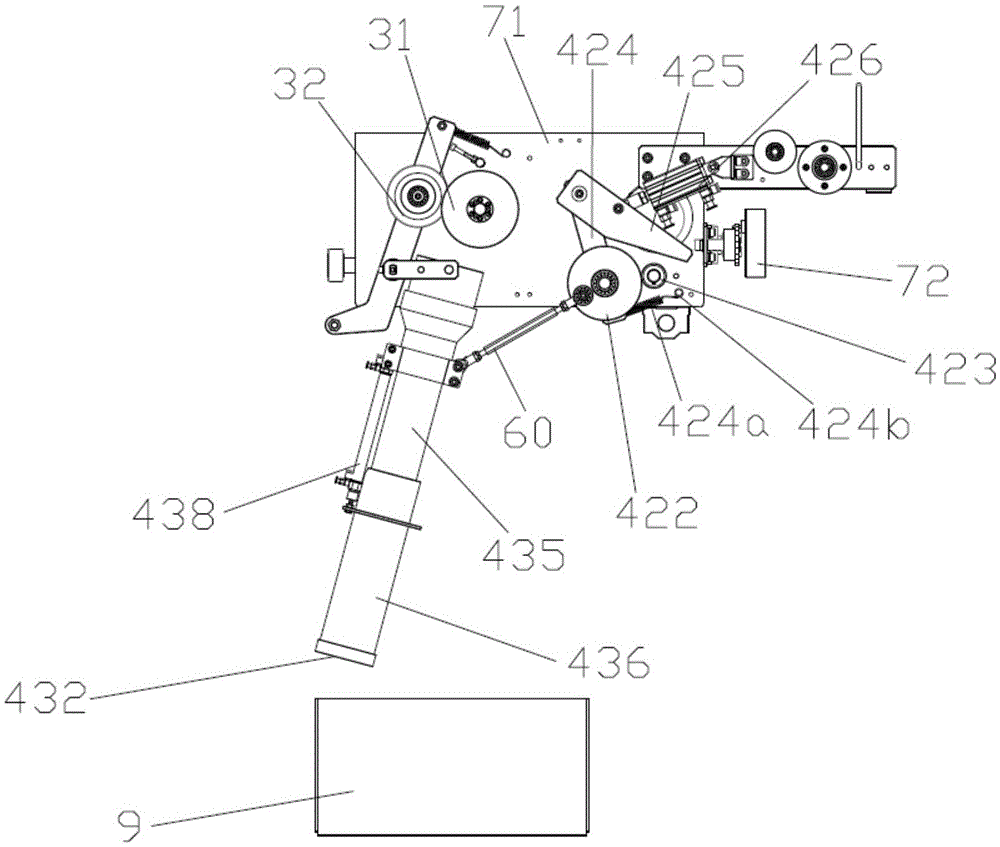

[0033] Such as Figure 1 to Figure 4 Shown, a kind of embodiment of a kind of automatic packaging machine 1 of the present invention comprises:

[0034] Frame 10, described frame 10 is successively provided with feeding device 20, feeding device 30 and tape-out device 40 and driving motor 77, and tape-in device 20 has metal inductor 212, and described tape-out device 40 comprises transverse Motion mechanism 45, swing mechanism 42 and tape out cylinder 43, described tape feeding device 30 is driven and connected with described drive motor 77, described swing mechanism 42 and tape out cylinder 43 are arranged on the transverse movement mechanism 45 and described lateral movement The mechanism 45 moves laterally under the drive of the drive motor 77, and the swing mechanism 42 drives the belt-out cylinder 43 to swing back and forth under the drive of the drive motor 77. The middle part of the belt-out cylinder 43 is connected and scalable, and has Inlet 431 and outlet 432, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com