Method for manufacturing liquid crystal panel and method for cutting substrate

A manufacturing method and liquid crystal panel technology, applied in the direction of manufacturing tools, instruments, laser welding equipment, etc., can solve problems such as coolant residue, and achieve the effects of improving yield, improving quality, and high-quality substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

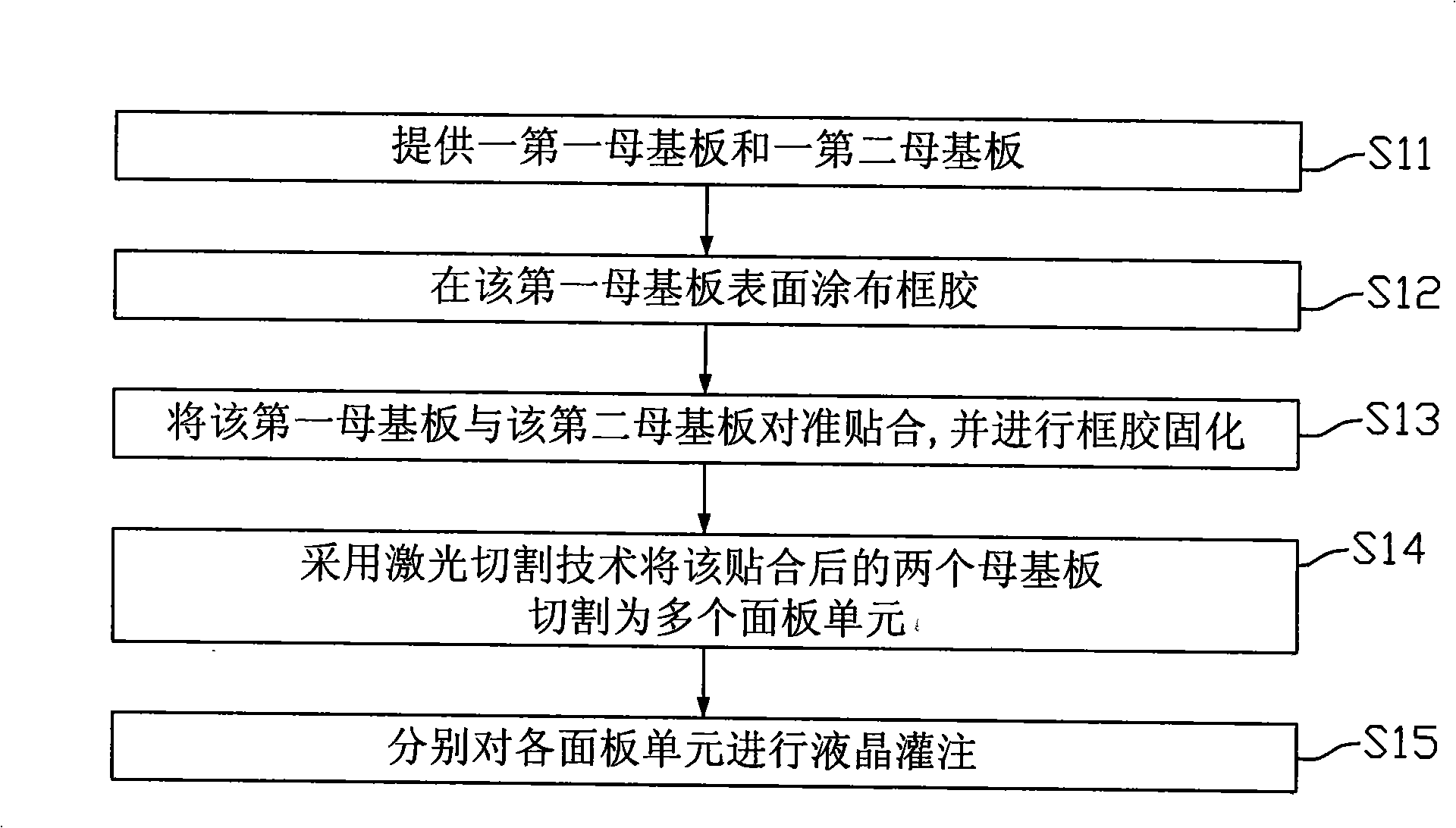

[0035] see figure 1 , is a flow chart of the first embodiment of the liquid crystal panel manufacturing method of the present invention. The manufacturing method of the liquid crystal panel includes the following steps: providing a first mother substrate and a second mother substrate; coating a sealant on the surface of the first mother substrate; aligning and laminating the first mother substrate and the second mother substrate , and curing the frame glue; cutting the laminated first and second mother substrates into multiple panel units by using laser cutting technology; performing liquid crystal perfusion on each panel unit respectively. Among them, the details of each step are as follows:

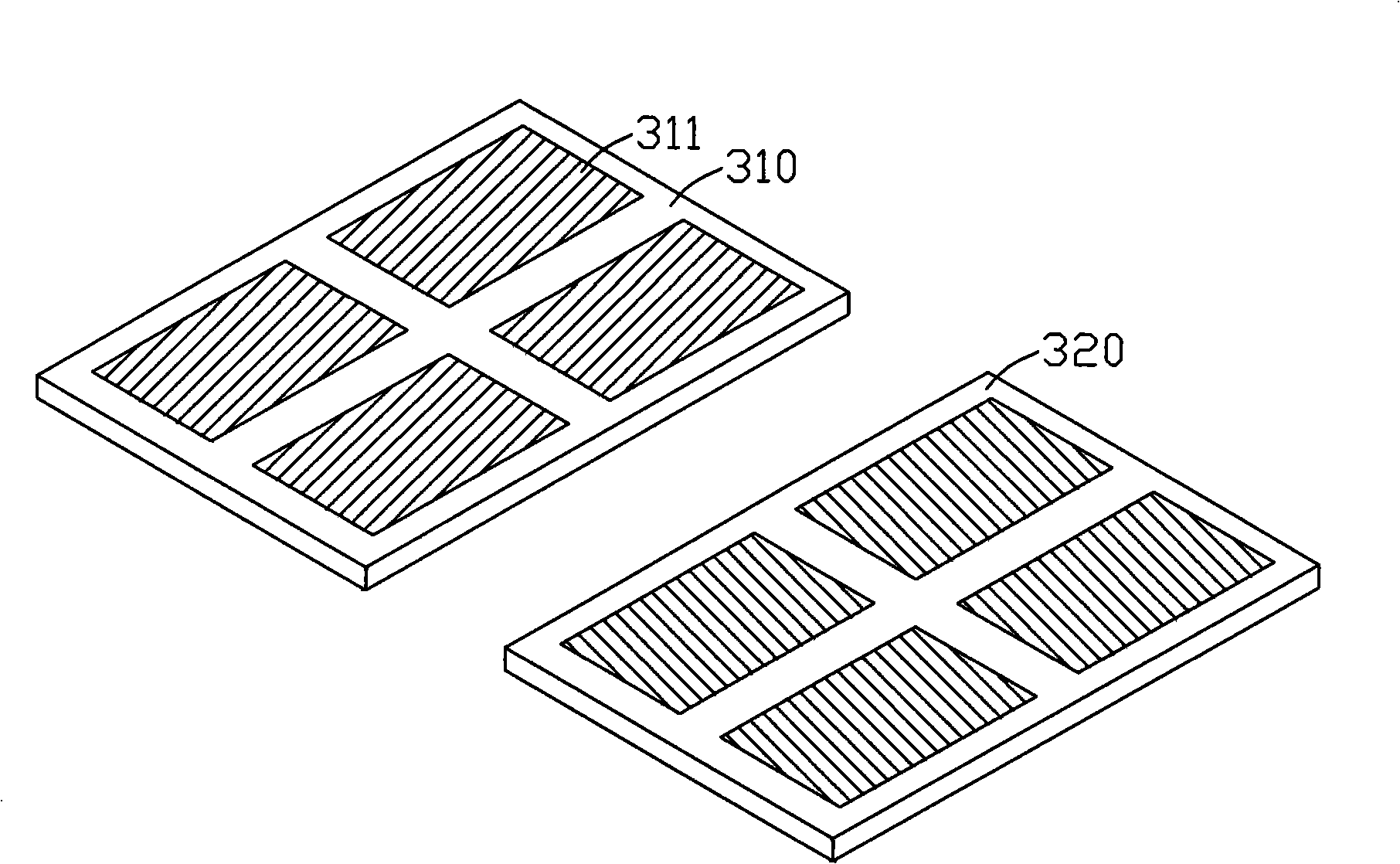

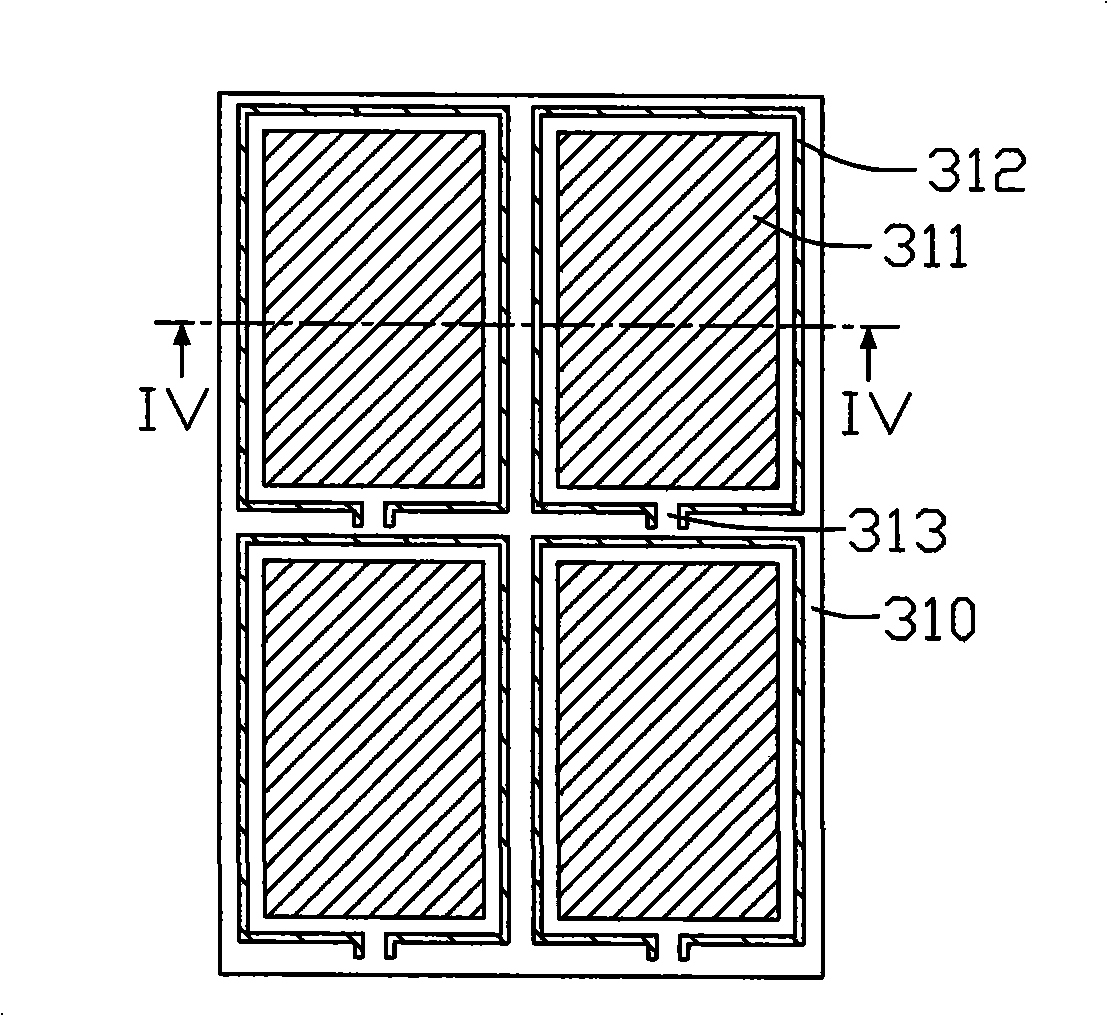

[0036] Step S11, providing a first motherboard 310 and a second motherboard 320;

[0037] Please also refer to figure 2 , is a schematic perspective view of the first mother substrate 310 and the second mother substrate 320 . The step S11 is specifically as follows: Firstly, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com