Material blocking device of reel

A blocking device and coiling technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of not conforming to the concept of intensive equipment manufacturing, increased maintenance workload, and increased equipment investment, etc., to achieve Good benefits, reduced equipment investment, and scientific force effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to better understand and implement the technical solutions of the present invention, some embodiments of the present invention are provided here. These examples are for better explaining the technical solutions of the present invention, and do not constitute any form of limitation to the present invention.

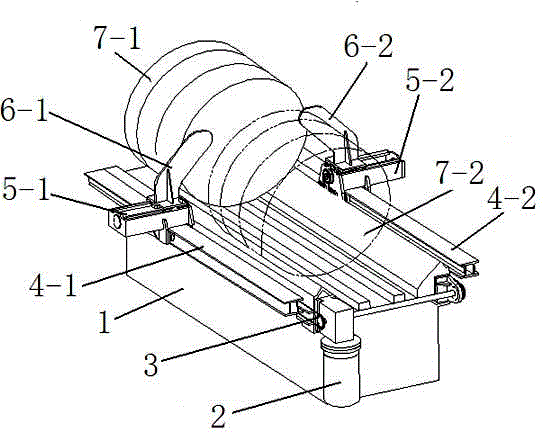

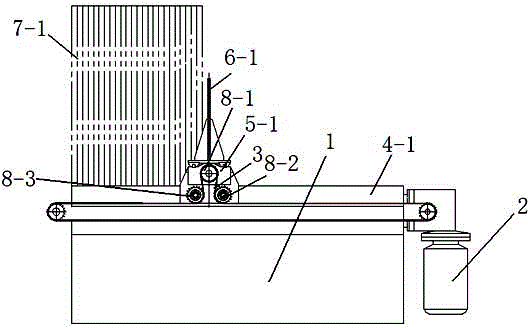

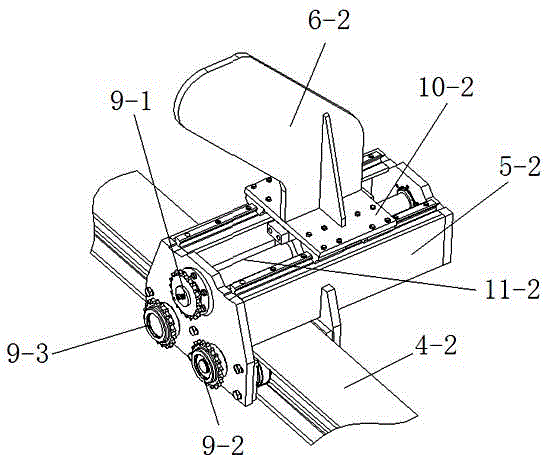

[0010] A coil stopper, comprising a frame, on which a transmission chain is arranged along the coil conveying direction, and a driving device for the transmission chain is provided, and the driving device is fixedly arranged on the frame, and a guide rail consistent with the direction of the chain is provided , the trolley is set on the guide rail, and the baffle is set on the trolley through the driving of the screw. The installation direction of the screw is perpendicular to the coil conveying direction, and the screw is connected to the trolley in rotation. The end of the sprocket is located at one end of the transmission chain. The main sprocket is driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com